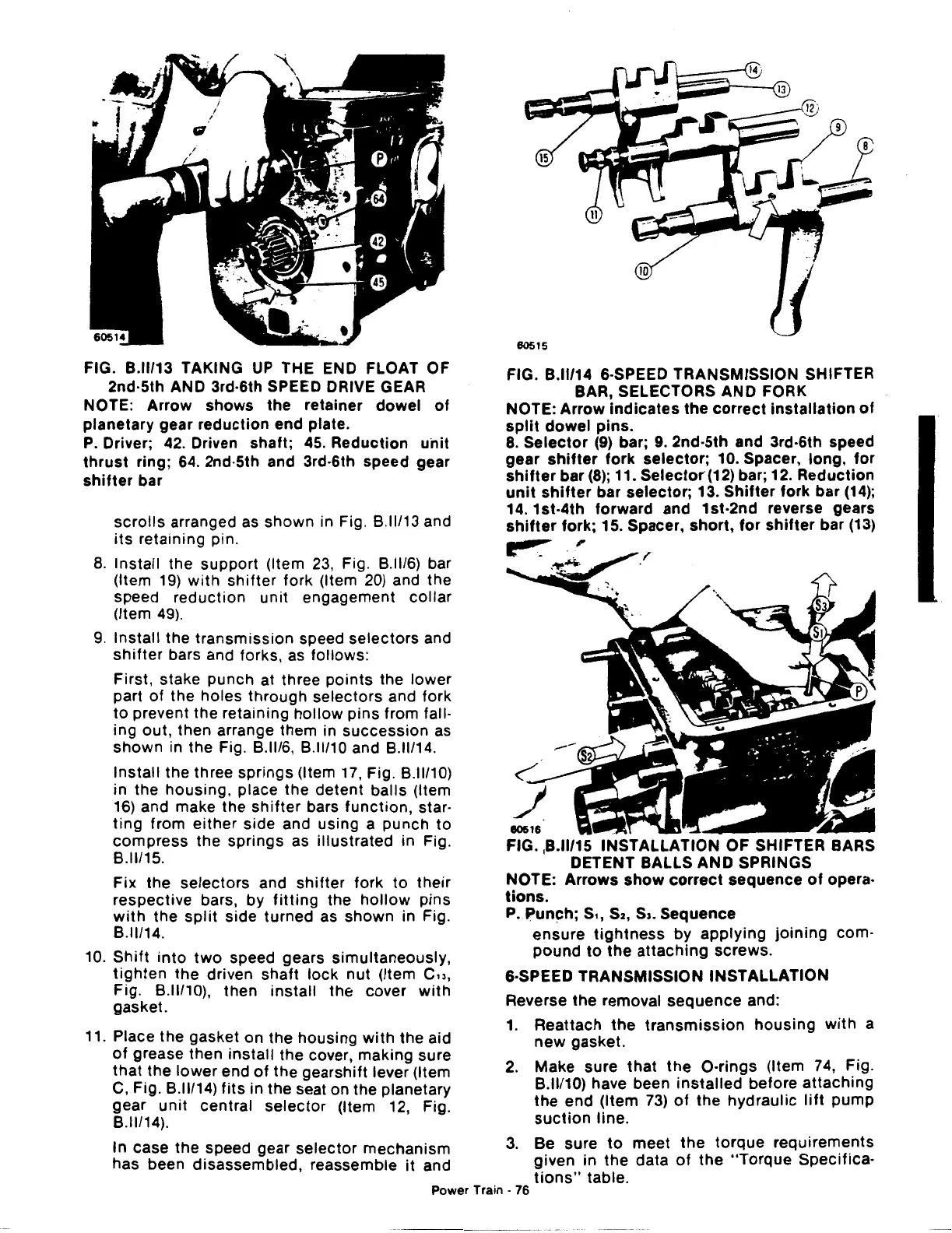

FIG. B.ll/13 TAKING

UP

THE END FLOAT OF

2nd-5th AND 3rd-6th SPEED DRIVE GEAR

NOTE: Arrow shows the retainer dowel

of

planetary gear reduction end plate.

P.

Driver; 42. Driven shaft; 45. Reduction

unit

thrust

ring;

64.

2nd-5th and 3rd-6th speed gear

shifter

bar

scrolls

arranged as shown in Fig.

8.11/13

and

its

retaining pin.

8.

Install the support (Item 23, Fig.

8.11/6)

bar

(Item

19)

with

shifter

fork (Item 20) and the

speed reduction unit engagement

collar

(Item

49).

9.

Install the

transmission

speed selectors and

shifter

bars and forks, as follows:

First, stake punch at three

points

the lower

part

of

the holes

through

selectors and fork

to

prevent the retaining

hollow

pins from fall-

ing out, then arrange them in succession as

shown in the Fig.

8.11/6,

8.11/10

and

8.11/14.

Install the three springs (Item 17, Fig.

8.11/10)

in the housing, place the detent

balls

(Item

16) and make the

shifter

bars

function,

star-

ting

from

either

side and using a punch

to

compress

the springs as illustrated in Fig.

8.11/15.

Fix the selectors and

shifter

fork

to

their

respective bars, by

fitting

the

hollow

pins

with

the

split

side turned as shown in Fig.

8.11114.

10.

Shift

into

two

speed gears simultaneously,

tighten

the driven shaft lock nut (Item

C13,

Fig.

8.11/10),

then install the cover

with

gasket.

11. Place the gasket on the housing

with

the aid

of

grease then install the cover, making sure

that the

lower

end

of

the gearshift lever (Item

C,

Fig.

8.11/14)

fits

in the seat on the planetary

gear

unit

central

selector

(Item 12, Fig.

8.11/14).

In case the speed gear selector mechanism

has been disassembled, reassemble

it

and

60515

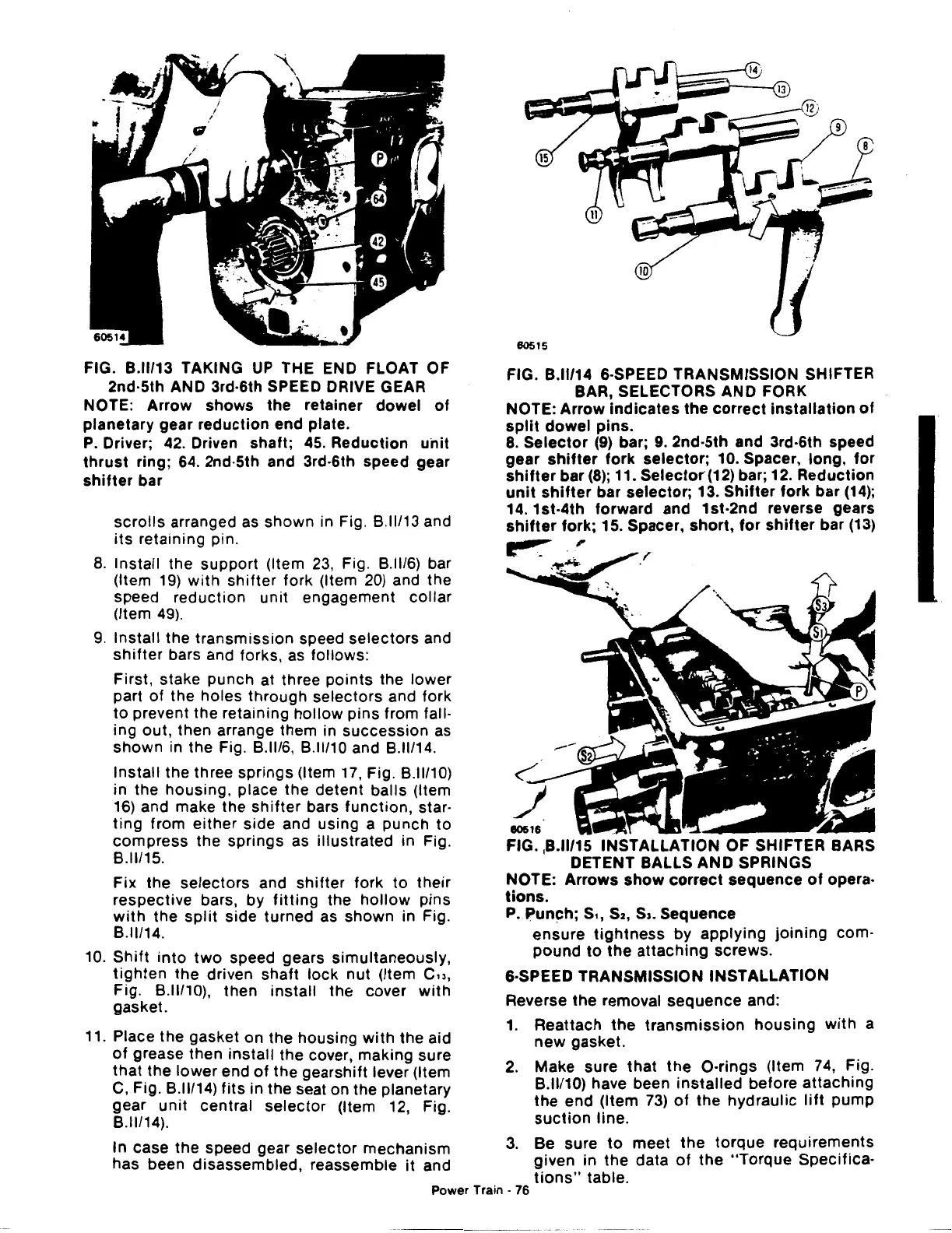

FIG. B.ll/14 &·SPEED TRANSMISSION SHIFTER

BAR, SELECTORS AND FORK

NOTE: Arrow

indicates

the

correct

installation

of

split

dowel

pins.

8.

Selector

(9)

bar;

9.

2nd-5th and 3rd·6th speed

gear

shifter

fork

selector;

10. Spacer, long,

for

shifter

bar

(8);

11.

Selector

(12) bar; 12. Reduction

unit

shifter

bar selector; 13.

Shifter

fork bar

(14);

14. 1st-4th forward and 1st·2nd reverse gears

shifter

fork; 15. Spacer,

short,

for

shifter

bar

(13)

~,

80516

FIG. ,B.II/15 INSTALLATION

OF

SHIFTER BARS

DETENT BALLS

AND

SPRINGS

NOTE: Arrows

show

correct

sequence

of

opera·

tions.

P.

,:»un~h;

s,,

S2,

s,. Sequence

ensure

tightness

by

applying

joining

com-

pound

to

the

attaching

screws.

&·SPEED TRANSMISSION INSTALLATION

Reverse the removal sequence and:

1.

Reattach

the

transmission

housing

with

a

new

gasket.

2.

Make sure

that

the

0-rings

(Item 74, Fig.

B.ll/10) have been

installed

before attaching

the

end (Item 73)

of

the hydraulic

lift

pump

suction

line.

3.

Be sure

to

meet

the

torque

requirements

given in

the

data

of

the

"Torque

Specifica·

tions"

table.

Power Train -

76

Loading...

Loading...