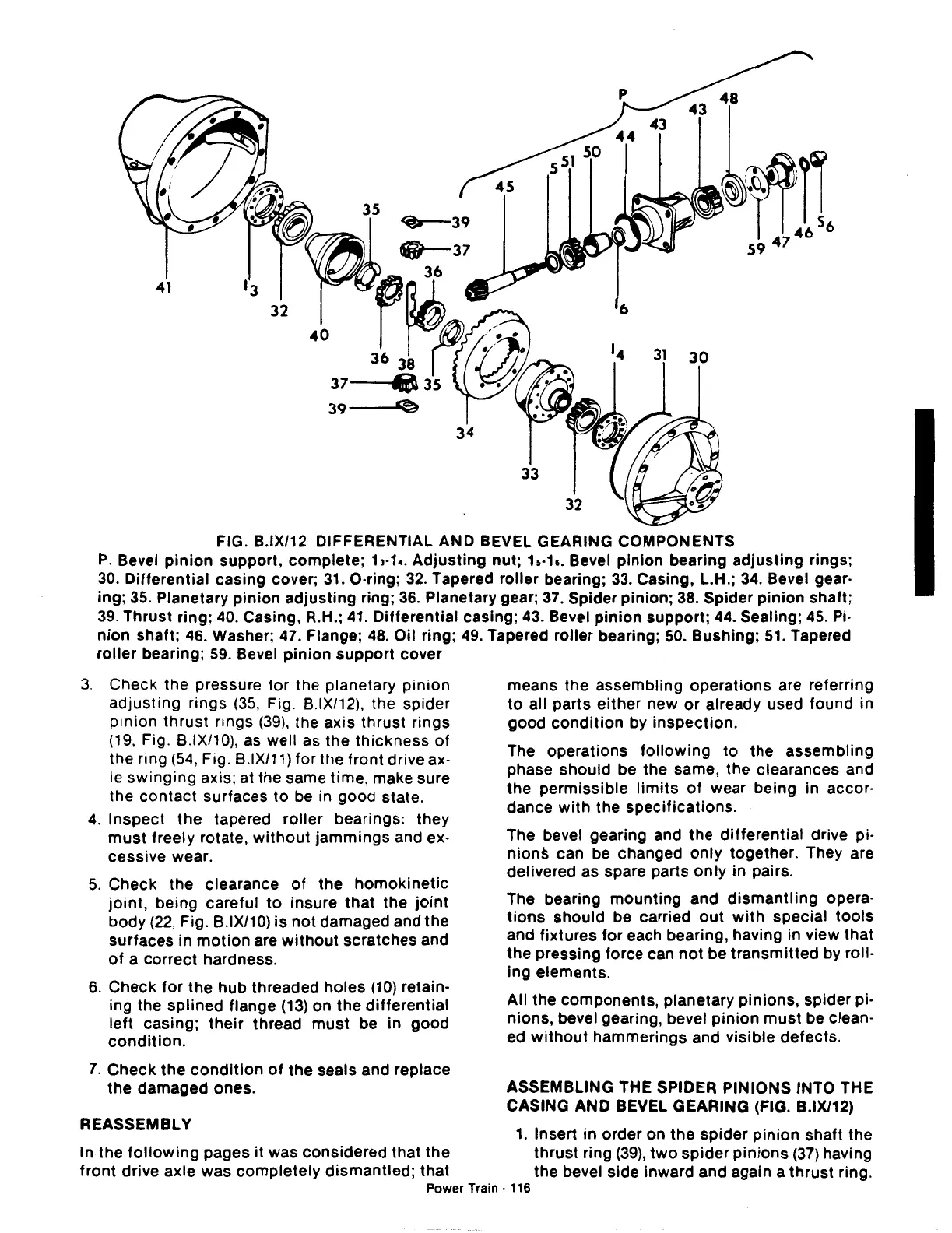

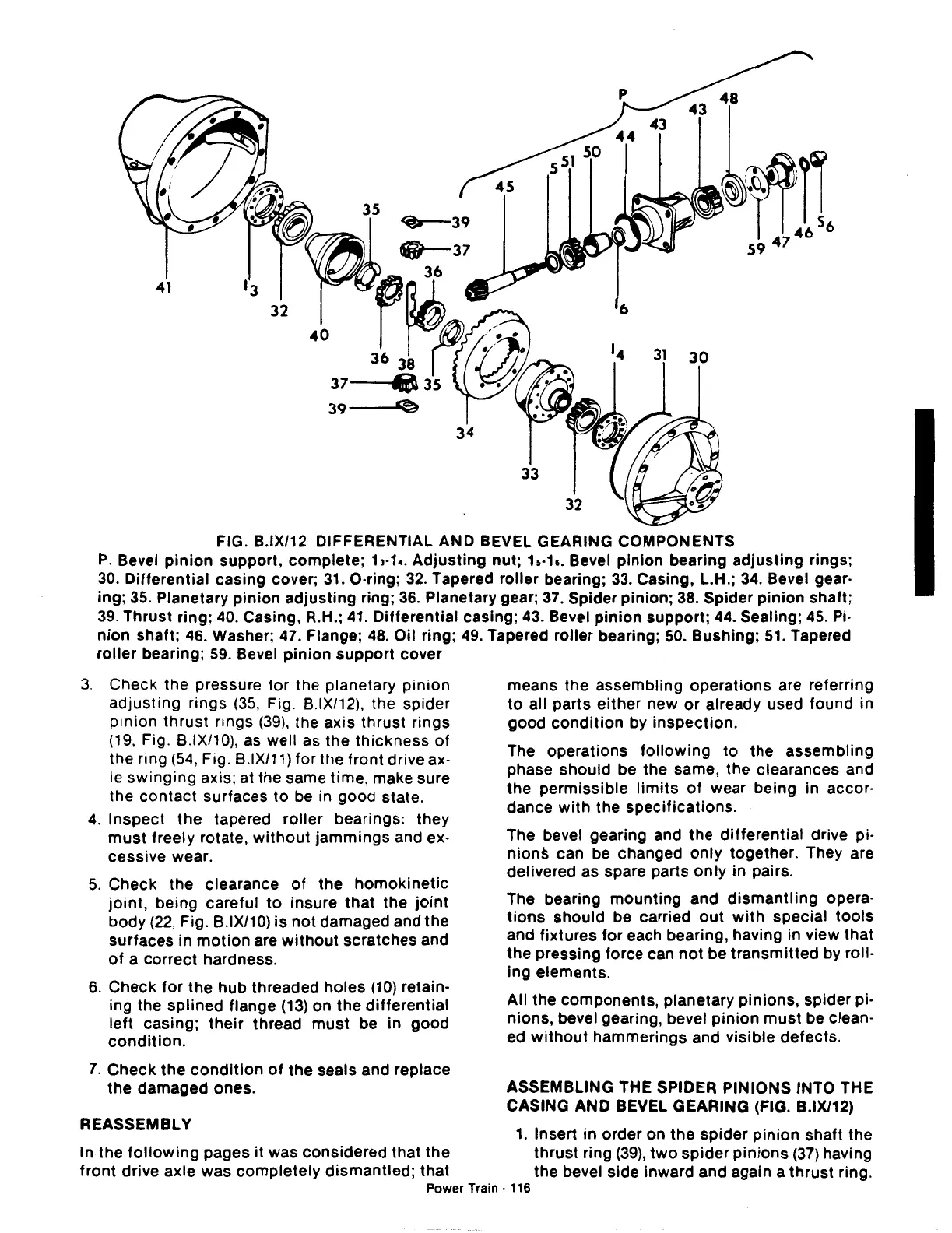

FIG. B.IX/12 DIFFERENTIAL AND BEVEL GEARING COMPONENTS

P.

Bevel

pinion

support,

complete;

13-1

•.

Adjusting

nut;

h·h.

Bevel

pinion

bearing

adjusting

rings;

30.

Differential

casing cover;

31.

0-ring;

32.

Tapered roller bearing;

33.

Casing, L.H.;

34.

Bevel gear-

ing;

35.

Planetary

pinion

adjusting

ring;

36.

Planetary gear;

37.

Spider pinion; 38. Spider

pinion

shaft;

39. Thrust ring; 40. Casing, R.H.; 41. Differential casing; 43. Bevel

pinion

support; 44. Sealing; 45. Pi-

nion

shaft; 46. Washer; 47. Flange;

48.

Oil ring;

49.

Tapered roller bearing;

50.

Bushing;

51.

Tapered

roller

bearing;

59.

Bevel

pinion

support

cover

3.

Check the pressure for the planetary

pinion

adjusting

rings

(35,

Fig. B.IX/12), the spider

pinion

thrust

rings

(39),

the axis thrust

rings

(19, Fig. B.IX/10), as well as the

thickness

of

the ring

(54,

Fig. B.IX/1

1)

for the front drive ax-

le

swinging

axis; at the same time, make sure

the

contact

surfaces

to

be in good state.

4.

Inspect

the

tapered

roller

bearings: they

must

freely rotate,

without

jammings

and ex-

cessive wear.

5.

Check

the

clearance

of

the

homokinetic

joint,

being careful

to

insure

that

the

joint

body

(22,

Fig. B.IX/10)

is

not

damaged and

the

surfaces

in

motion

are

without

scratches

and

of

a

correct

hardness.

6.

Check

for

the

hub

threaded

holes

(10)

retain-

ing

the

splined

flange

(13)

on

the

differential

left

casing;

their

thread

must

be in

good

condition.

7.

Check

the

condition

of

the

seals and replace

the

damaged

ones.

REASSEMBLY

means the assembling operations are referring

to

all parts

either

new

or

already used found in

good

condition

by

inspection.

The operations

following

to

the

assembling

phase should be the same, the clearances and

the permissible

limits

of

wear being in accor-

dance

with

the

specifications.

The bevel gearing and

the

differential

drive pi-

nions

can be changed

only

together. They are

delivered as spare parts

only

in pairs.

The bearing

mounting

and

dismantling

opera-

tions

should be carried

out

with

special

tools

and fixtures

for

each bearing, having in view that

the pressing force can

not

be

transmitted

by roll-

ing elements.

All the components, planetary pinions, spider pi-

nions, bevel gearing, bevel

pinion

must

be clean-

ed

without

hammerings and visible defects.

ASSEMBLING THE SPIDER PINIONS INTO THE

CASING AND BEVEL GEARING (FIG. B.IX/12)

1.

Insert in order on

the

spider

pinion

shaft the

In the

following

pages

it

was considered that

the

thrust

ring

(39),

two

spider

pinions

(37)

having

front

drive axle was

completely

dismantled;

that

the bevel side inward and again a

thrust

ring.

Power

Train-

116

Loading...

Loading...