8.11

TRANSMISSION

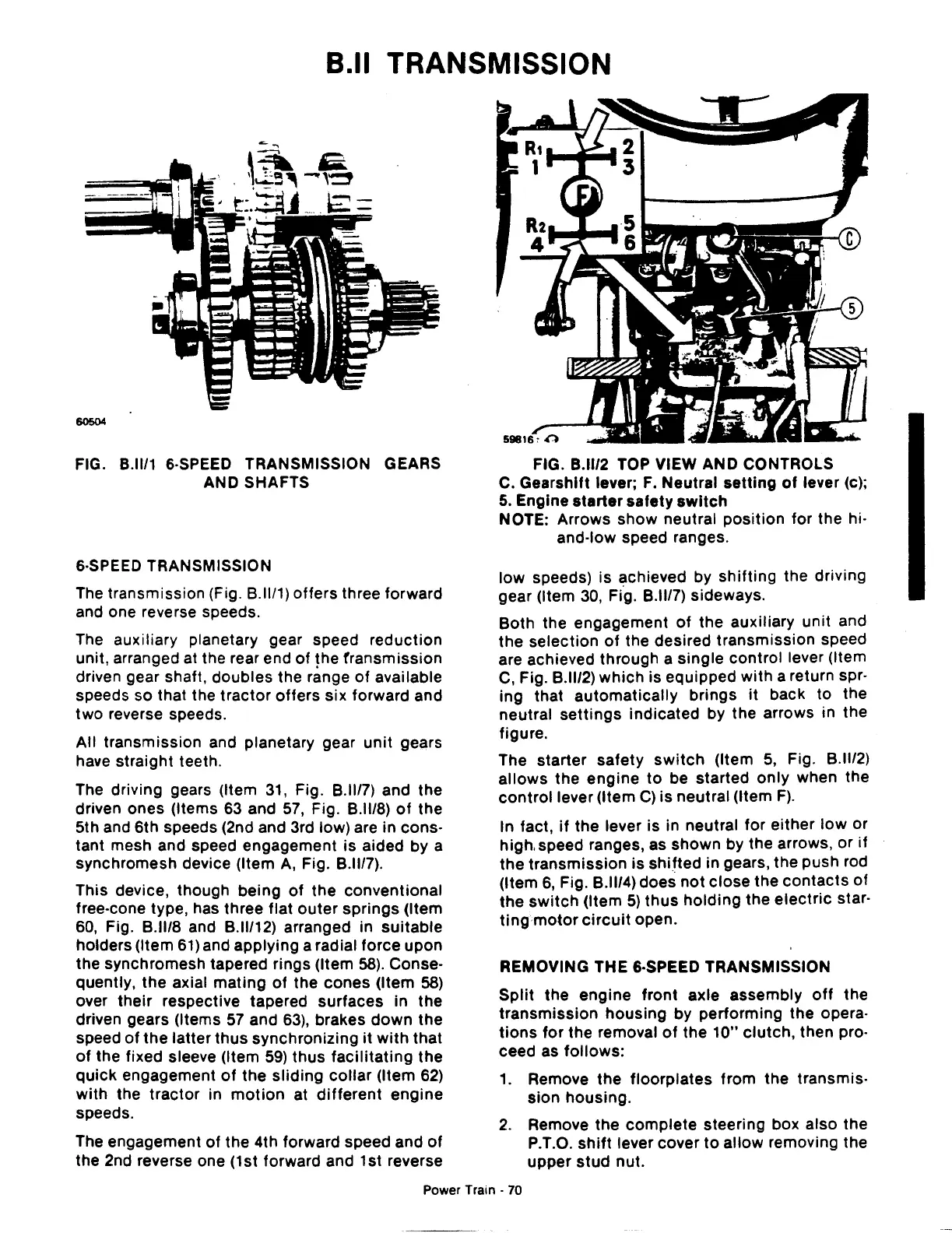

FIG.

8.11/1

6-SPEED TRANSMISSION GEARS

AND SHAFTS

6-SPEED TRANSMISSION

The transmission (Fig. B.ll/1)

offers

three forward

and one reverse speeds.

The auxiliary planetary gear speed

reduction

unit, arranged at the rear end

of

the

transmission

driven gear shaft,

doubles

the range

of

available

speeds so that the

tractor

offers

six

forward and

two

reverse speeds.

All transmission and planetary gear

unit

gears

have straight teeth.

The driving gears (Item

31,

Fig.

8.1117)

and the

driven ones (Items 63 and

57,

Fig.

8.1118)

of

the

5th and 6th speeds (2nd and 3rd low) are in cons-

tant mesh and speed engagement

is

aided by a

synchromesh device (Item

A,

Fig. B.ll/7).

This device, though being

of

the

conventional

free-cone type, has three flat

outer

springs

(Item

60,

Fig.

8.1118

and B.ll/12) arranged in

suitable

holders (Item

61)

and

applying

a radial force upon

the synchromesh tapered rings (Item

58).

Conse-

quently,

the

axial

mating

of

the cones (Item

58)

over

their

respective tapered

surfaces

in

the

driven gears (Items

57

and 63), brakes

down

the

speed

of

the

latter

thus

synchronizing

it

with

that

of

the fixed sleeve (Item

59)

thus

facilitating

the

quick

engagement

of

the

sliding

collar

(Item 62)

with

the

tractor

in

motion

at

different

engine

speeds.

The engagement

of

the 4th forward speed and

of

the 2nd reverse one (1st forward and 1st reverse

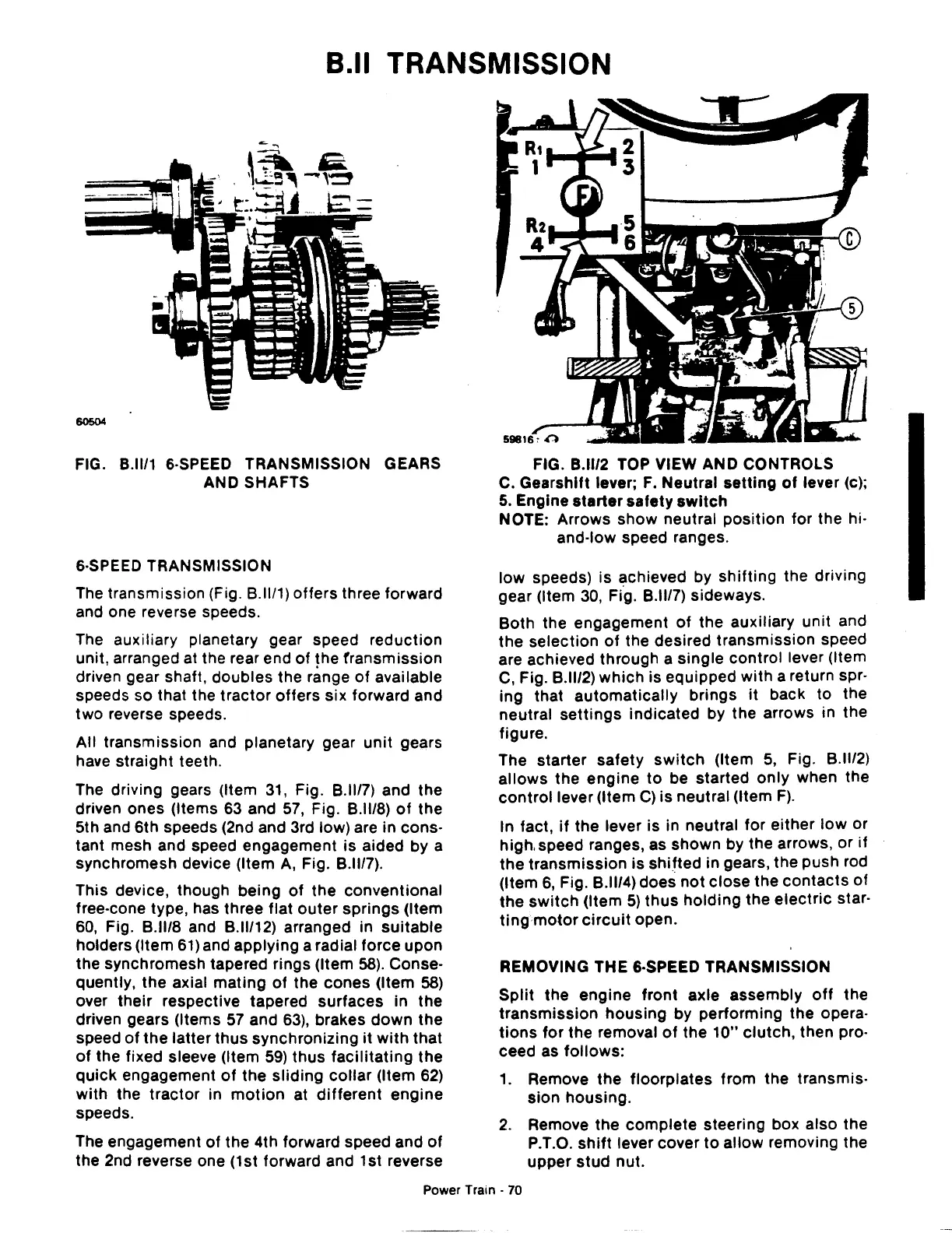

FIG.

8.11/2

TOP VIEW AND CONTROLS

C. Gearshift lever;

F.

Neutral

setting

of

lever (c);

5.

Engine

starter

safety

switch

NOTE: Arrows

show

neutral

position

for

the hi·

and-low speed ranges.

low

speeds) is achieved by

shifting

the driving

gear (Item

30,

Fi.g.

B.ll/7) sideways.

Both

the engagement

of

the auxiliary unit and

the

selection

of

the desired

transmission

speed

are achieved

through

a

single

control lever (Item

C, Fig.

8.11/2)

which

is equipped

with

a return spr-

ing that

automatically

brings

it

back

to

the

neutral

settings

indicated

by the arrows in the

figure.

The

starter

safety

switch

(Item

5,

Fig. B.ll/2)

allows

the

engine

to

be started

only

when the

control

lever (Item

C)

is

neutral (Item

F).

In fact,

if

the lever

is

in neutral

for

either

low

or

high. speed ranges, as shown by the arrows, or

if

the

transmission

is

shifted

in gears, the push rod

(Item

6,

Fig.

8.1114)

does

not

close

the

contacts

of

the

switch

(Item

5)

thus

holding

the

electric

star-

ting

motor

circuit

open.

REMOVING THE &·SPEED TRANSMISSION

Split

the

engine

front

axle

assembly

off

the

transmission

housing

by

performing

the opera-

tions

for

the

removal

of

the

10"

clutch,

then pro-

ceed as

follows:

1.

Remove

the

floorplates

from

the transmis-

sion

housing.

2.

Remove

the

complete

steering box also the

P.T.O.

shift

lever cover

to

allow

removing the

upper

stud

nut.

Power Train -

70

Loading...

Loading...