After

every 250 hours

of

work, clean the

first

fuel

filter

(Item

a,

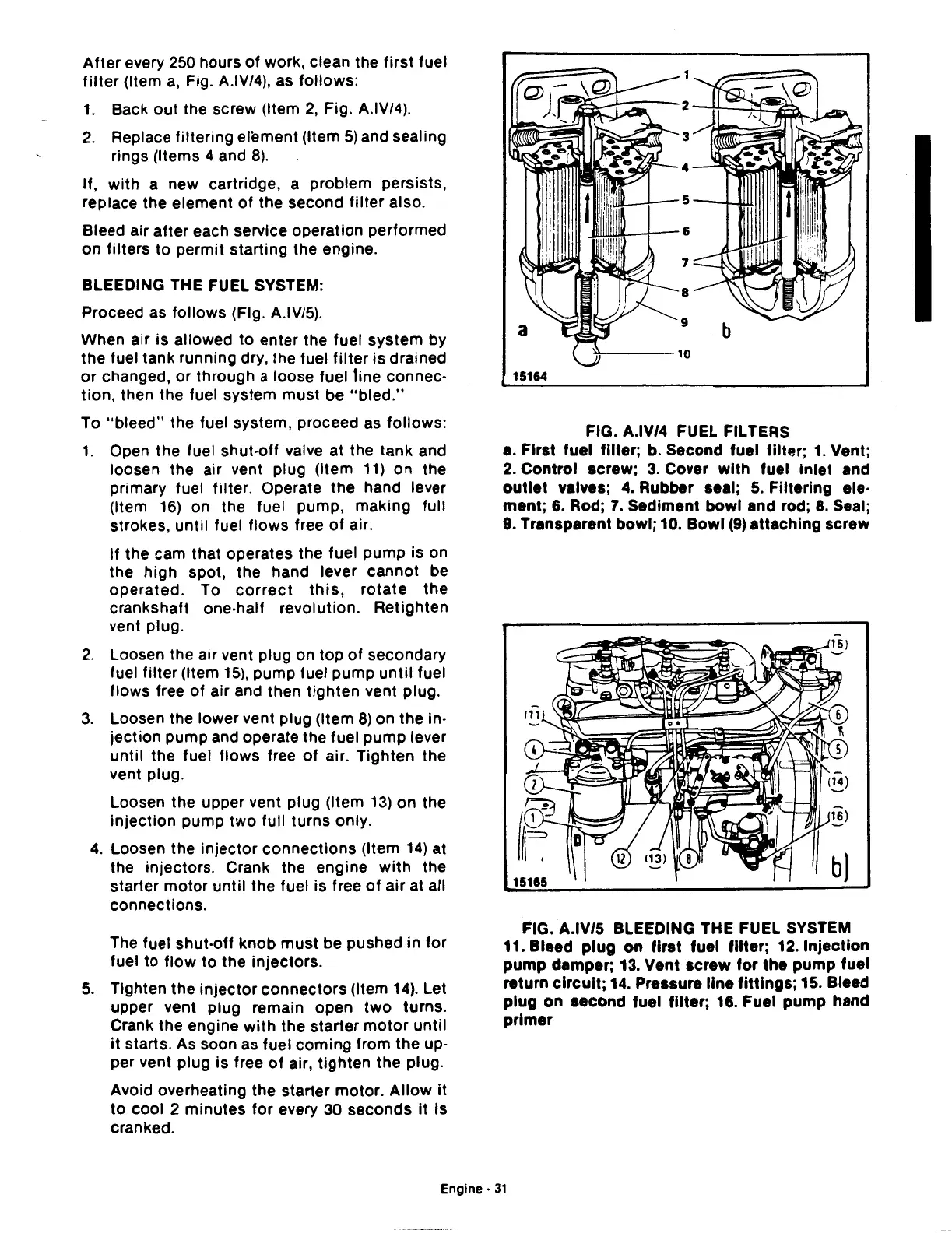

Fig. A.IV/4), as follows:

1.

Back

out

the screw (Item

2,

Fig. A.IV/4).

2.

Replace filtering element (Item

5)

and sealing

rings (Items 4 and

8).

If,

with

a new cartridge, a problem persists,

replace the element

of

the second

filter

also.

Bleed air

after

each service operation performed

on

filters

to

permit starting the engine.

BLEEDING THE FUEL SYSTEM:

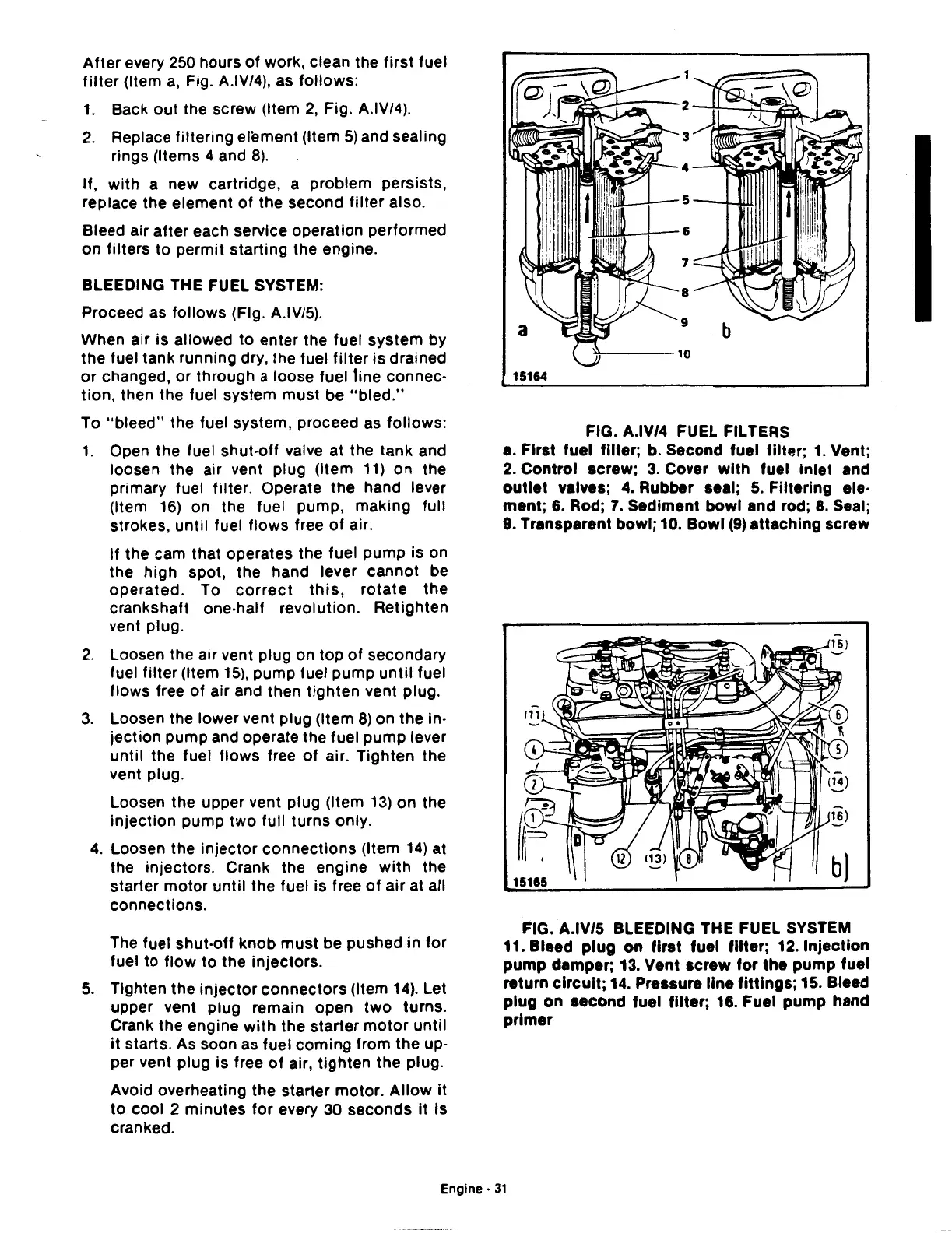

Proceed as follows (Fig. A.IV/5).

When air is allowed

to

enter the fuel

system

by

the

fuel tank running dry, the fuel

filter

is

drained

or

changed,

or

through a loose fuel fine connec·

tion,

then the fuel system

must

be

"bled."

To

"bleed"

the fuel system, proceed as follows:

1.

Open

the

fuel shut-off valve at the tank and

loosen the air vent plug (Item 1

1) on the

primary fuel filter. Operate the hand lever

(Item

16)

on the fuel pump, making full

strokes, until fuel flows free

of

air.

If

the cam that operates the fuel

pump

is

on

the

high

spot, the hand lever

cannot

be

operated.

To

correct

this,

rotate

the

crankshaft one-half revolution. Retighten

vent plug.

2.

Loosen the air vent plug on

top

of

secondary

fuel

filter

(Item

15),

pump fuel pump

until

fuel

flows free

of

air and then

tighten

vent plug.

3.

Loosen the lower vent plug (Item 8) on the in·

jection pump and operate the fuel

pump

lever

until

the fuel

flows

free

of

air. Tighten the

vent plug.

Loosen the upper vent plug (Item

13)

on the

injection

pump

two

full turns only.

4.

Loosen the

injector

connections

(Item

14)

at

the injectors. Crank the engine

with

the

15164

FIG. A.IV/4 FUEL FILTERS

a.

First fuel filter; b. Second fuel filter;

1.

Vent;

2.

Control screw;

3.

Cover with fuel inlet and

outlet

valves;

4.

Rubber seal;

5.

Filtering ele·

ment;

6.

Rod;

7.

Sediment bowl and rod;

8.

Seal;

9.

Transparent bowl; 10. Bowl

(9)

attaching screw

starter

motor

until

the fuel is free

of

air

at all

~1.:.:5:.:.16:.:5;_

______________

__

connections.

The fuel shut-off knob

must

be pushed in

for

fuel

to

flow

to

the injectors.

5.

Tighten the

injector

connectors

(Item

14).

Let

upper vent plug remain open

two

turns.

Crank

the

engine

with

the

starter

motor

until

it

starts. As soon as fuel

coming

from the up-

per vent plug is free

of

air,

tighten

the

plug.

Avoid overheating the starter motor.

Allow

it

to

cool 2

minutes

for

every 30 seconds

it

is

cranked.

FIG. A.IV/5 BLEEDING THE FUEL SYSTEM

11. Bleed plug on first fuel filter; 12. Injection

pump damper; 13. Vent screw for the pump fuel

return

circuit;

14. Pressure line fittings; 15. Bleed

plug on second fuel filter; 16. Fuel pump hand

primer

Engine·

31

Loading...

Loading...