Set Up and Maintenance

9836 3521 01 195

4.17.3.4 Wind Up Coefficient

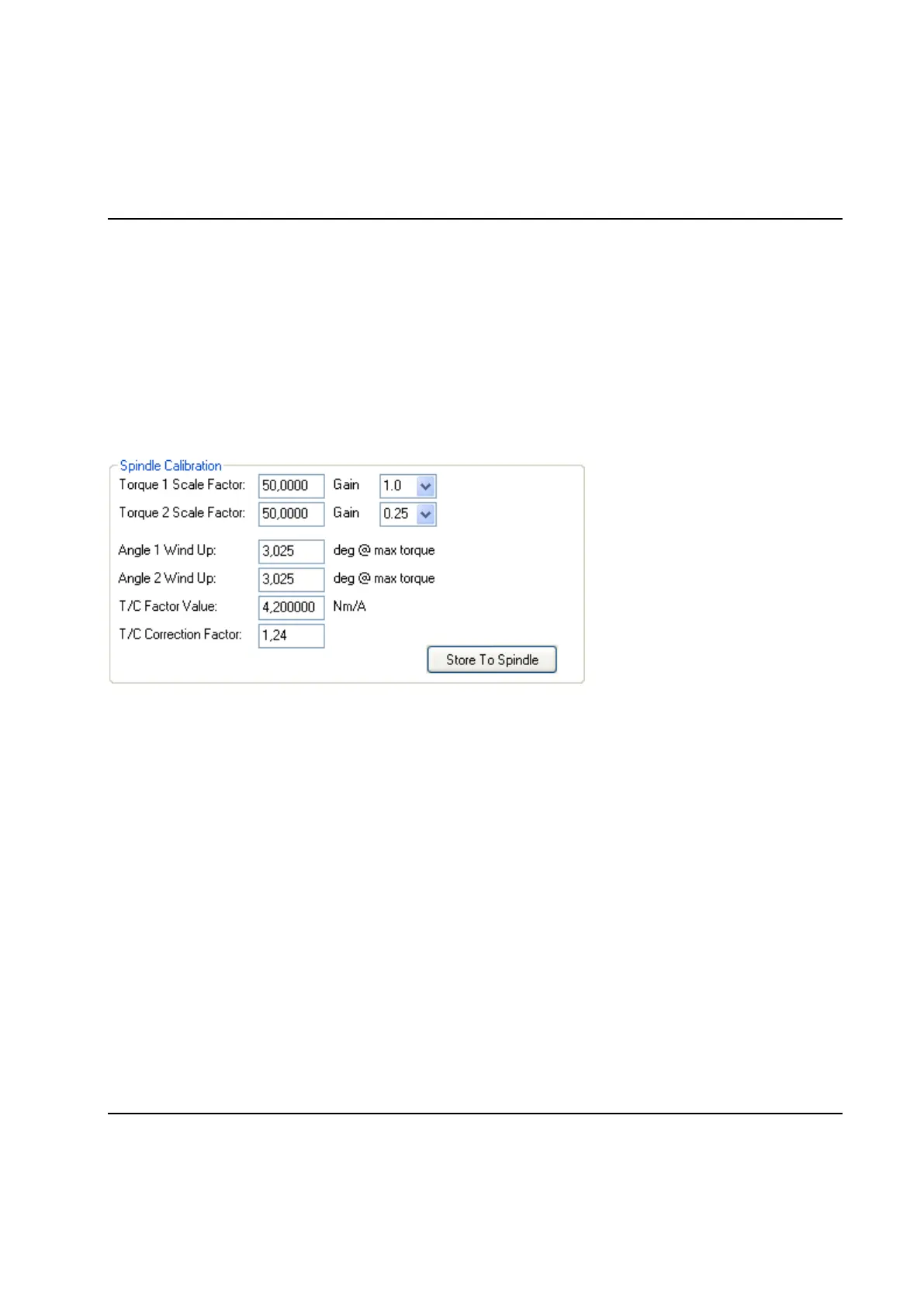

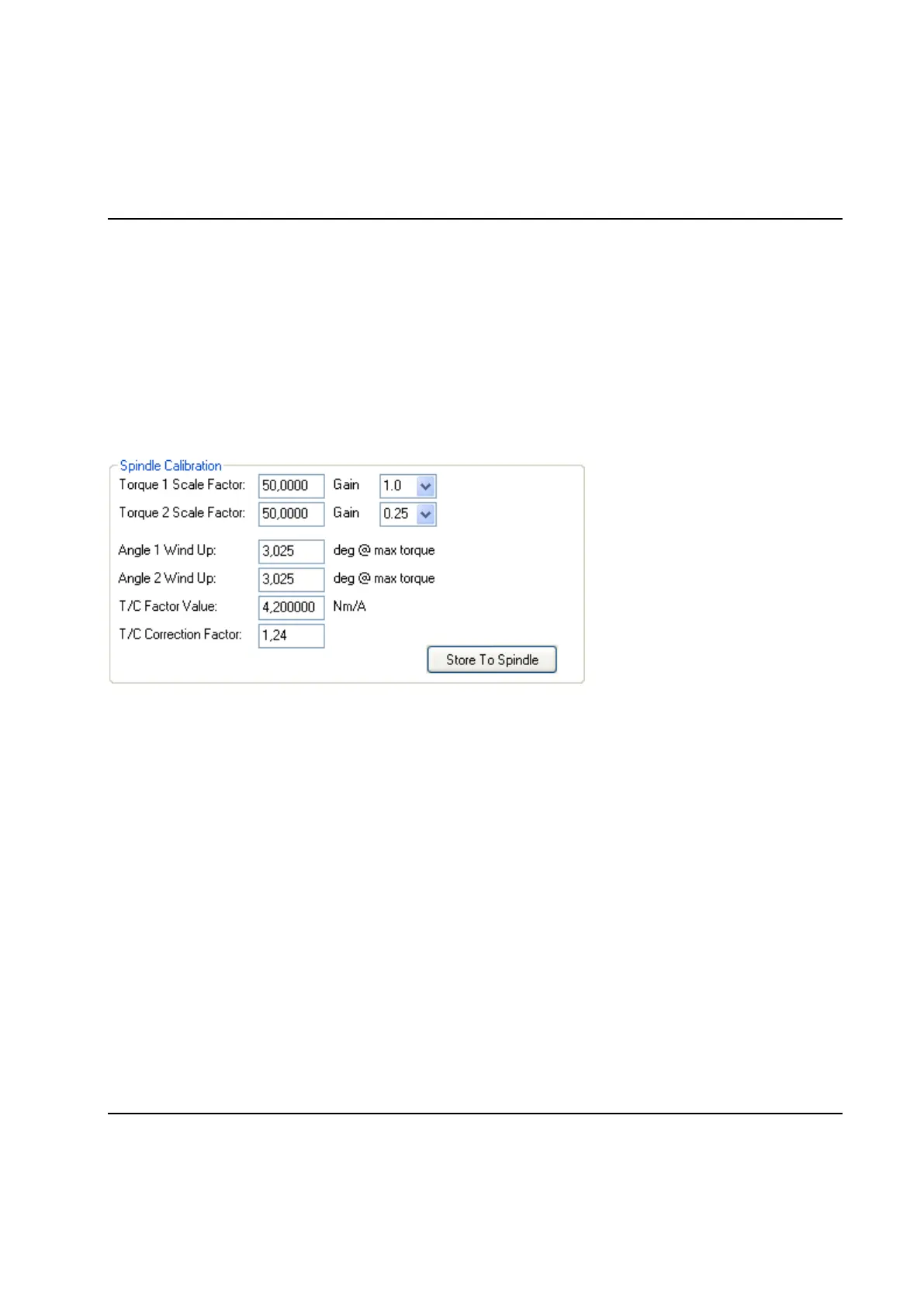

There is a spindle parameter, named Wind Up Coefficient (see Spindle Set Up, Calibration page), which

is used to compensate for the torsion in the mechanical parts (gears and shafts) between the electric

motor shaft and the square drive. The coefficient can be modified in order to fine tune systems where

external mechanics (like long thin extension shafts) affects the angle control.

The default value of the Wind Up Coefficient is 3 degrees at max spindle torque (that is, the value of

parameter Max Torque).

Note! The default Wind Up Coefficient is normally good enough and is in most cases not necessary to

change.

Calibration of the Wind Up Coefficient

It is fairly simple to check and to calibrate the Wind Up Coefficient.

Create a simple tightening program that has a Diagnostic step, a Torque step and a Cycle End.

Program a “high” torque in the T-step, the speed 5 rpm and the Speed Ramp 100 rpm/s. The “high”

torque shall be as much as the screw joint can stand without destroying it and that the spindle can

give.

Set the Wind Up Coefficient to the value 0.000 deg.

Run a number of times on the joint without loosening it between in order to have a test joint that is

not moving anymore.

Look at the trace showing Torque vs. Angle. Estimate the angle between two torque levels and

calculate the new Wind Up Coefficient. See the example below. The new value of the Wind Up

Coefficient will be: 3.5 / 45 * 50 (Spindle Max Torque) = 3,88 deg/Nm

Loading...

Loading...