PLC

9836 3521 01 235

5.3.3 ID device variables

The following input and outputs can be used to control and monitor the Stations Work piece identifier

function. See chapter: Advanced Station Settings for this is set up.

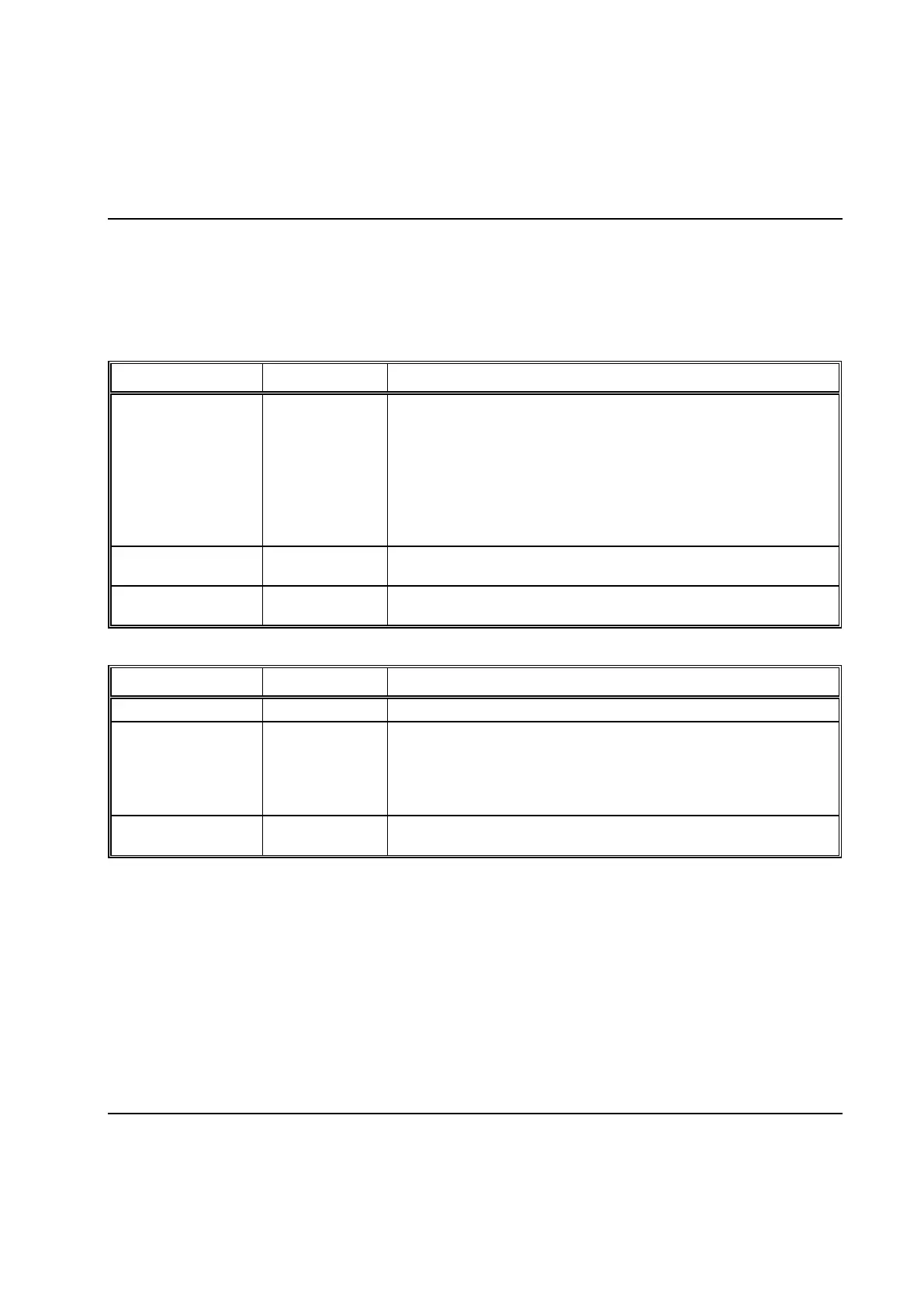

Inputs:

Status for ID device read or write operation:

0: Idle and OK

1: Idle and NOK

2: Busy

Note that the read ID string is not valid until this signal is 0. After

issuing an IDREAD you should always wait one PLC scan before

evaluating IDSTATUS.

This input always reflects the ID string known by the station. Will be

included in the cycle data as the station level variable "Wp ID".

Code from conversion of read ID string. See chapters: Conversion

table for how the conversion is defined.

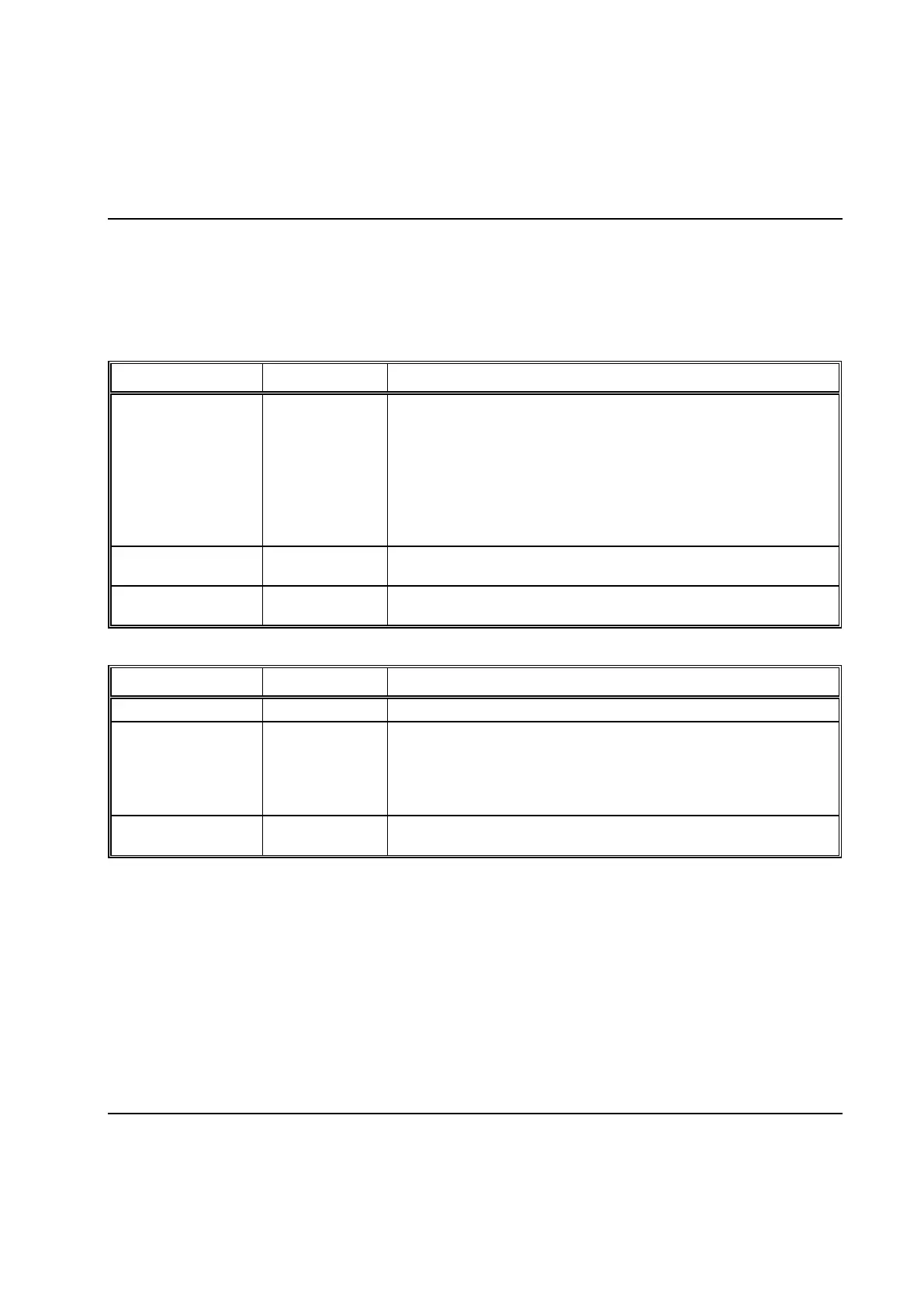

Outputs:

Set to True to order reading of ID device connected to the station.

Set to True to replace the ID string currently known by the station with

the value of IDSTRING.

If the station is connected to an ID device this device will be used to

generate a corresponding IDCODE. The written value will be echoed

back to CURRIDSTRING.

String to replace the ID string currently known by the station.

Sampled on the positive edge of IDWRITE.

The station will only use an ID string once. When it starts a cycle it will clear its internal ID string, and

therefore also CURRIDSTRING, and then set the value of IDCODE to –32768.

Depending on which type of ID device that is used a read operation may take differently long time. For a

barcode reader the last string scanned by the operator is stored internally by PowerMACS system so

completing a read is done within less a few milliseconds. However, for devices of Escort memory, where

the external data tag is read using a communication protocol, a read operation may take much longer

time. You should therefore always check the input IDSTATUS to make sure that a read string is available

to the station before you issue a start order.

Loading...

Loading...