Tightening

274 9836 3521 01

6.5.2.1 DT - Run until Dyna-Tork

TM

Step type Id: 1

Parameters: T (Torque), TI1 (Time1), TI2 (Time2), PERC (Current percentage), DIR (Direction).

Function: Run spindle, in DIR direction, until torque is T using current control. When the target is

reached a new torque, DT, is calculated as

DT = T * PERC / 100

The torque DT is then retained during the next TI1 + TI2 seconds using current control.

The PERC parameter makes it is possible to Dyna-Tork

TM

at a lower level than the target.

Before the step is started both torques, T and DT, are converted to corresponding motor

currents using the spindle parameters T/C Factor, T/C Correction Factor and Gear ratio.

When the step starts the current that corresponds to T is set as current reference to the

motor servo. When the servo reaches this current the step immediately switches the current

reference to the current that corresponds to DT which then is maintained for TI1 + TI2

seconds.

Note: To avoid overheating of the spindle it is strongly recommended to never run Dyna-

Tork

TM

to more than 40% of the maximum torque of the spindle.

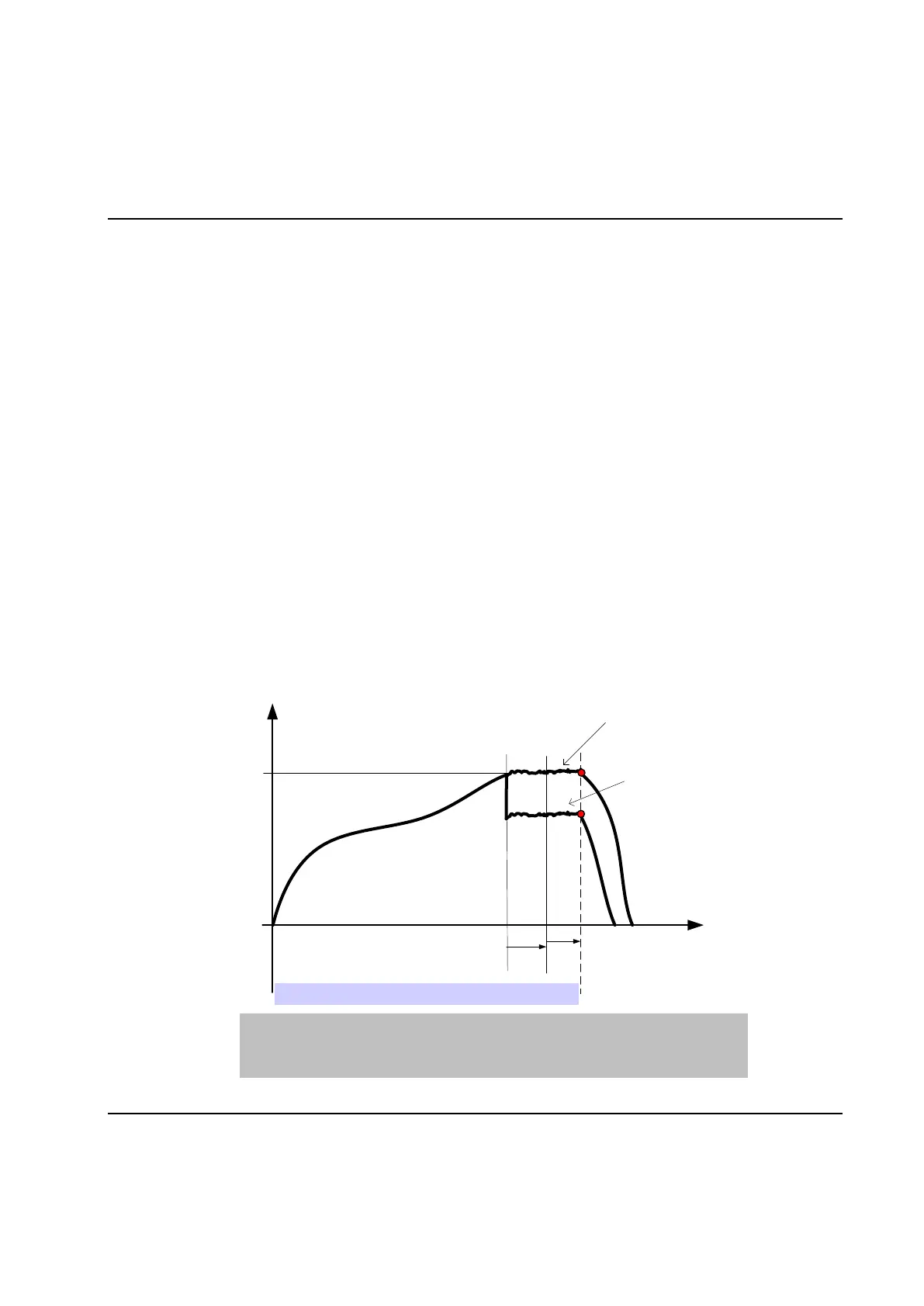

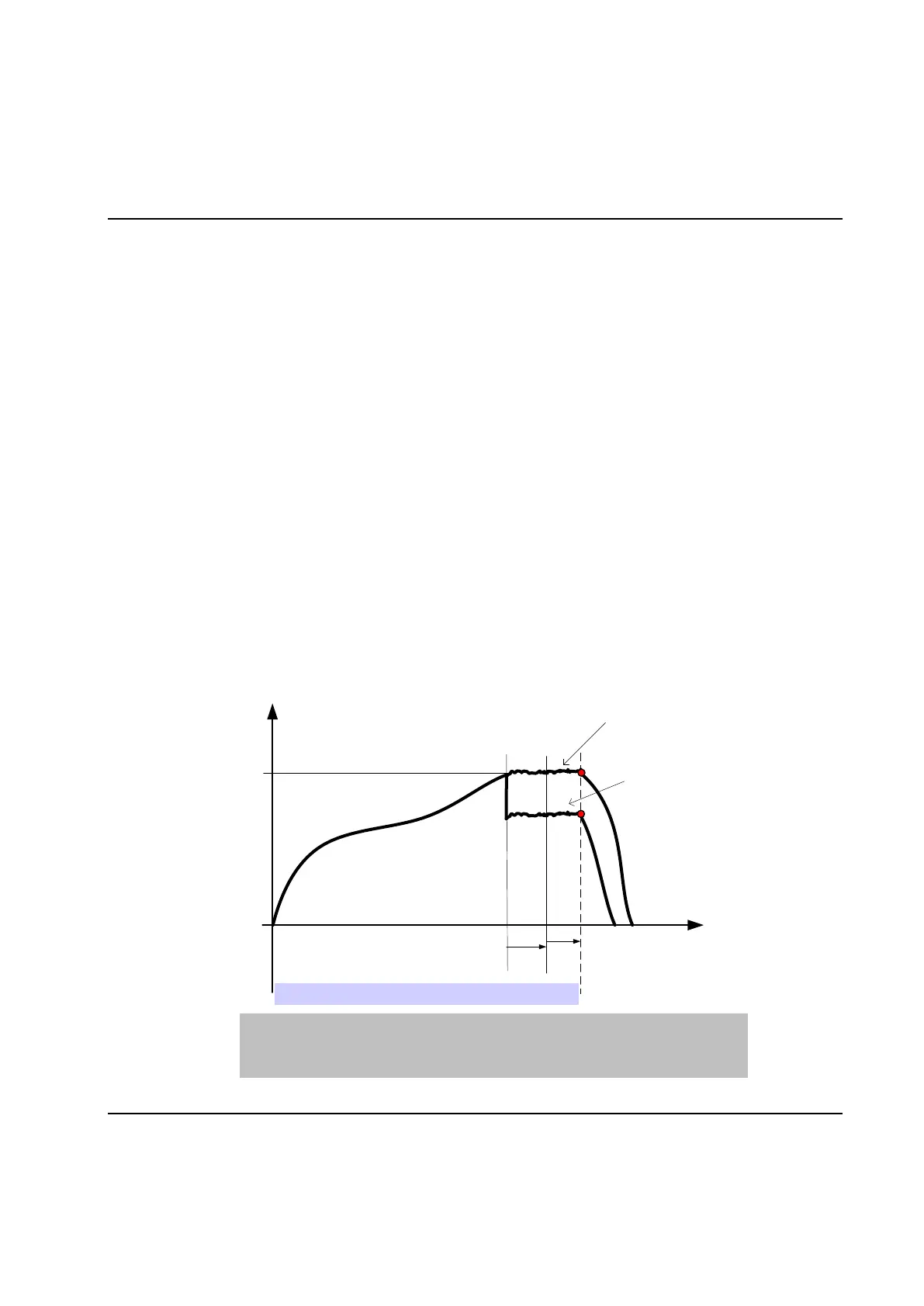

Diagram:

Time

Torque

TI1

TI2

T Torque TI1 DynaTork Time 1

PERC Percent of T TI2 DynaTork Time 2

DT Torque level retained during TI1 and TI2

T

Step

DT (PERC = 100%)

DT (PERC = 80%)

Loading...

Loading...