SPC and Statistics

408 9836 3521 01

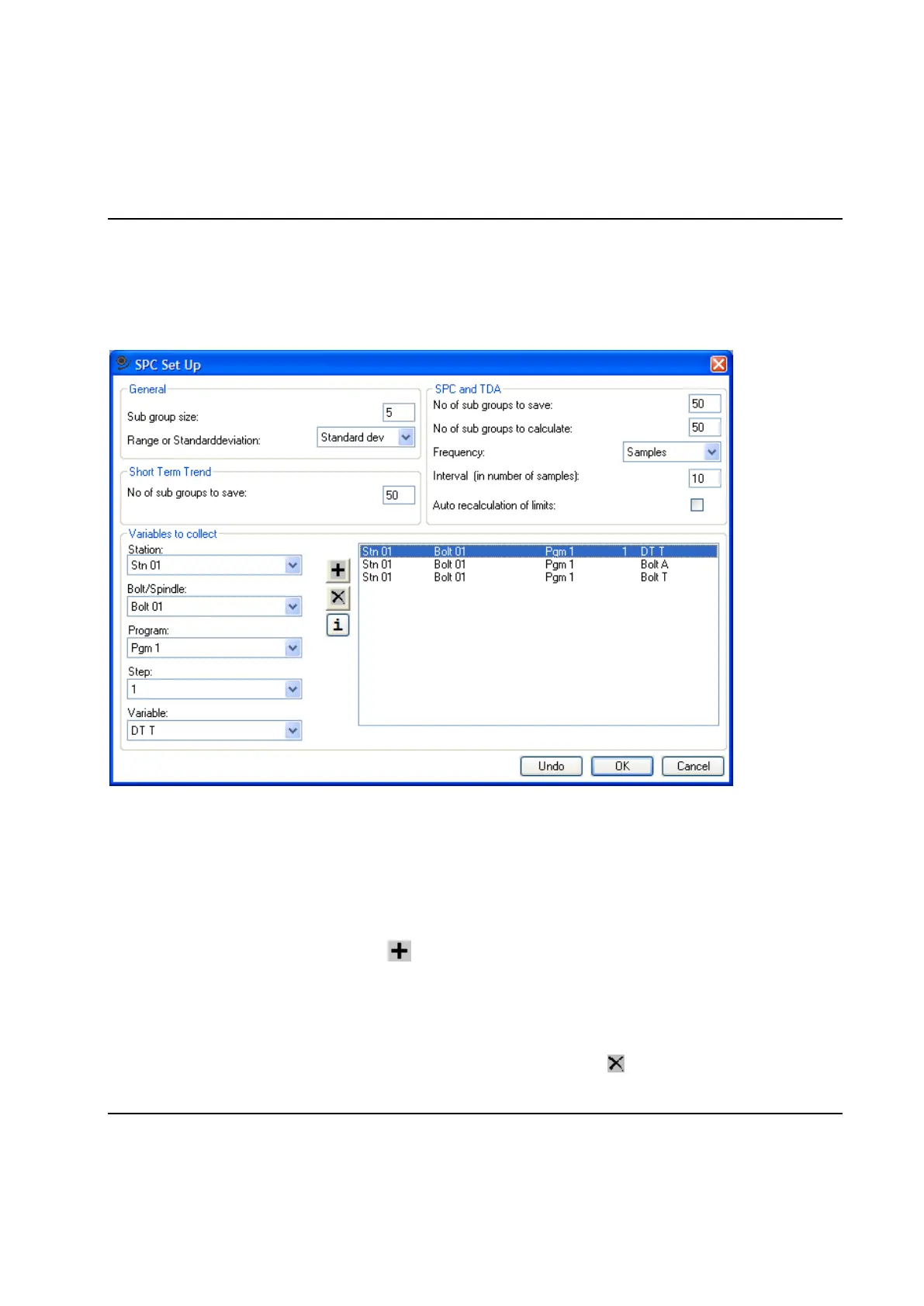

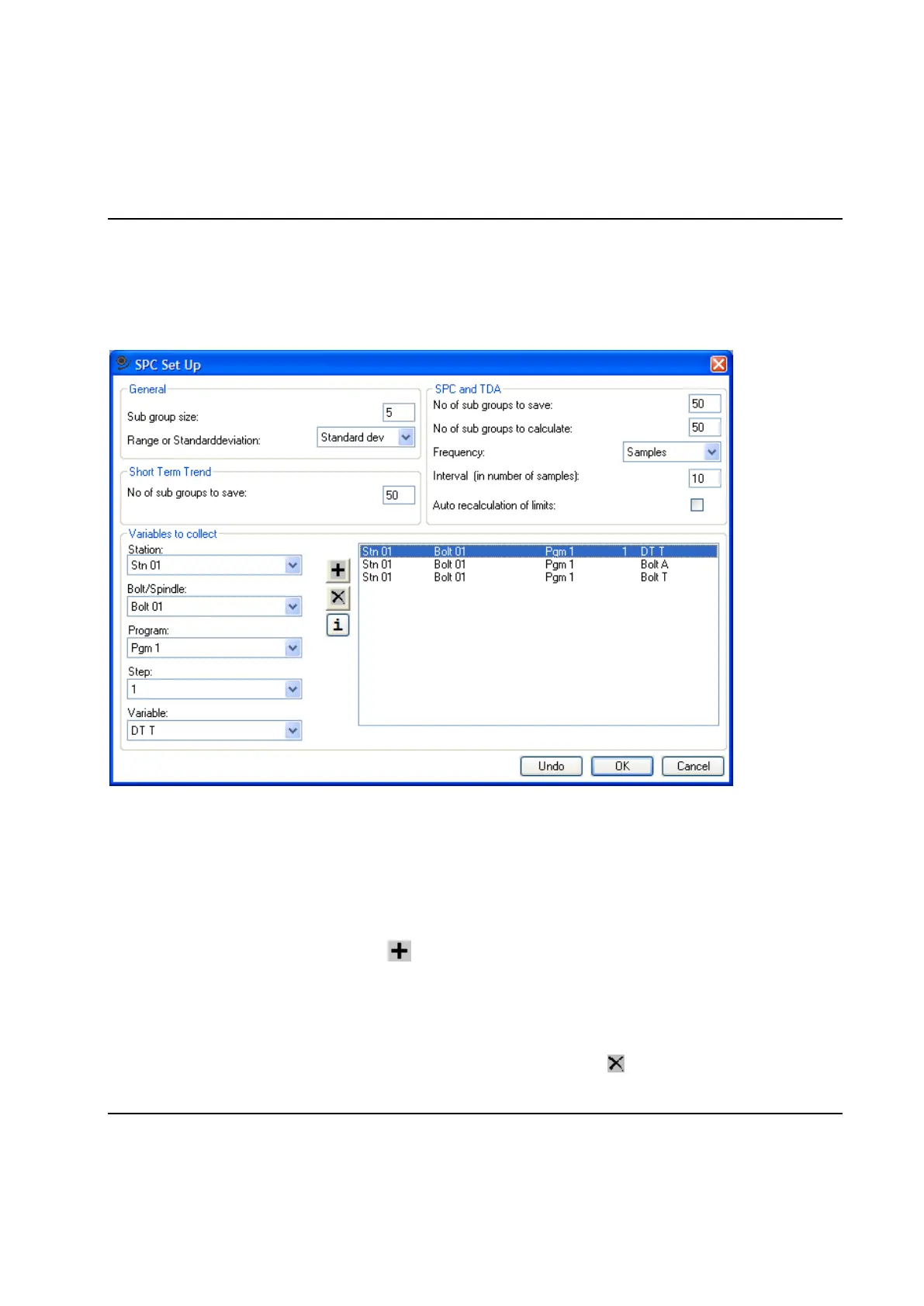

7.3 SPC set up

This form is used for configuration of the SPC, Statistical Process Control function. It is opened using the

Statistics SPC - Set Up menu item.

Specify Subgroup size and if you want to use Range or Standard Deviation.

In the SPC and TDA frame, set up values for normal SPC and Trend Deviation Alarms.

Do the same for the Short Term Trend frame. These values will be used for calculations of all variables

you choose to calculate on. See chapter: Data Collection for a description of the parameters.

In the Variables to collect frame, add those variables you want to check. Select Station, Bolt and/or

Spindle, Program, Variable and Step. For Bolt and/or Spindle you may specify All, this will add the

variable for all bolts in the station. Press . The variable shows up in the list box.

If more than one spindle can be used to tighten a bolt (defined in the Mode Table) you must define which

spindle for the bolt to collect data for.

A PowerMACS system may contain up to 200 SPC variables and max 20 per TC/spindle.

To remove a variable from the list, select it and press the remove button .

Loading...

Loading...