PLC

236 9836 3521 01

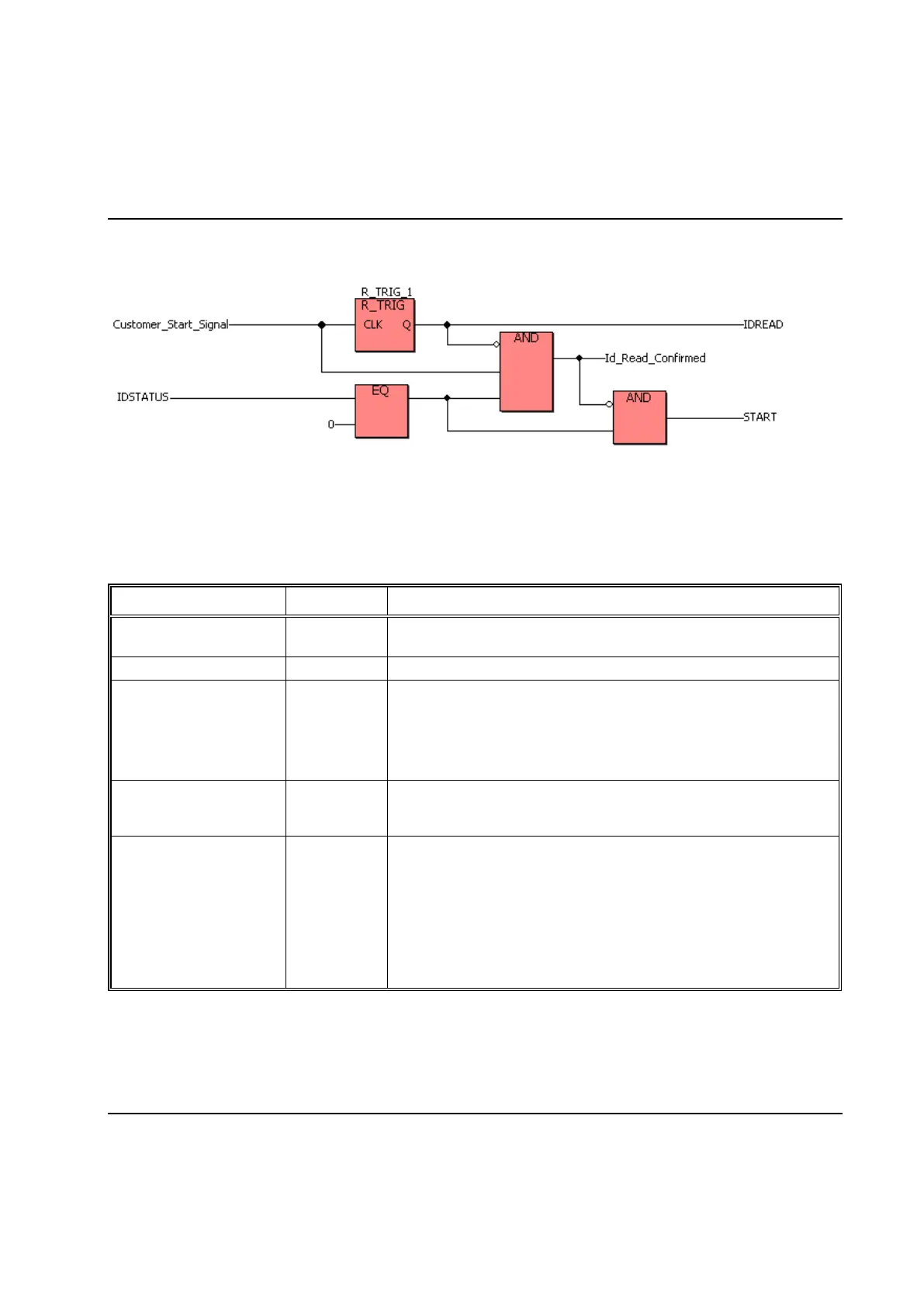

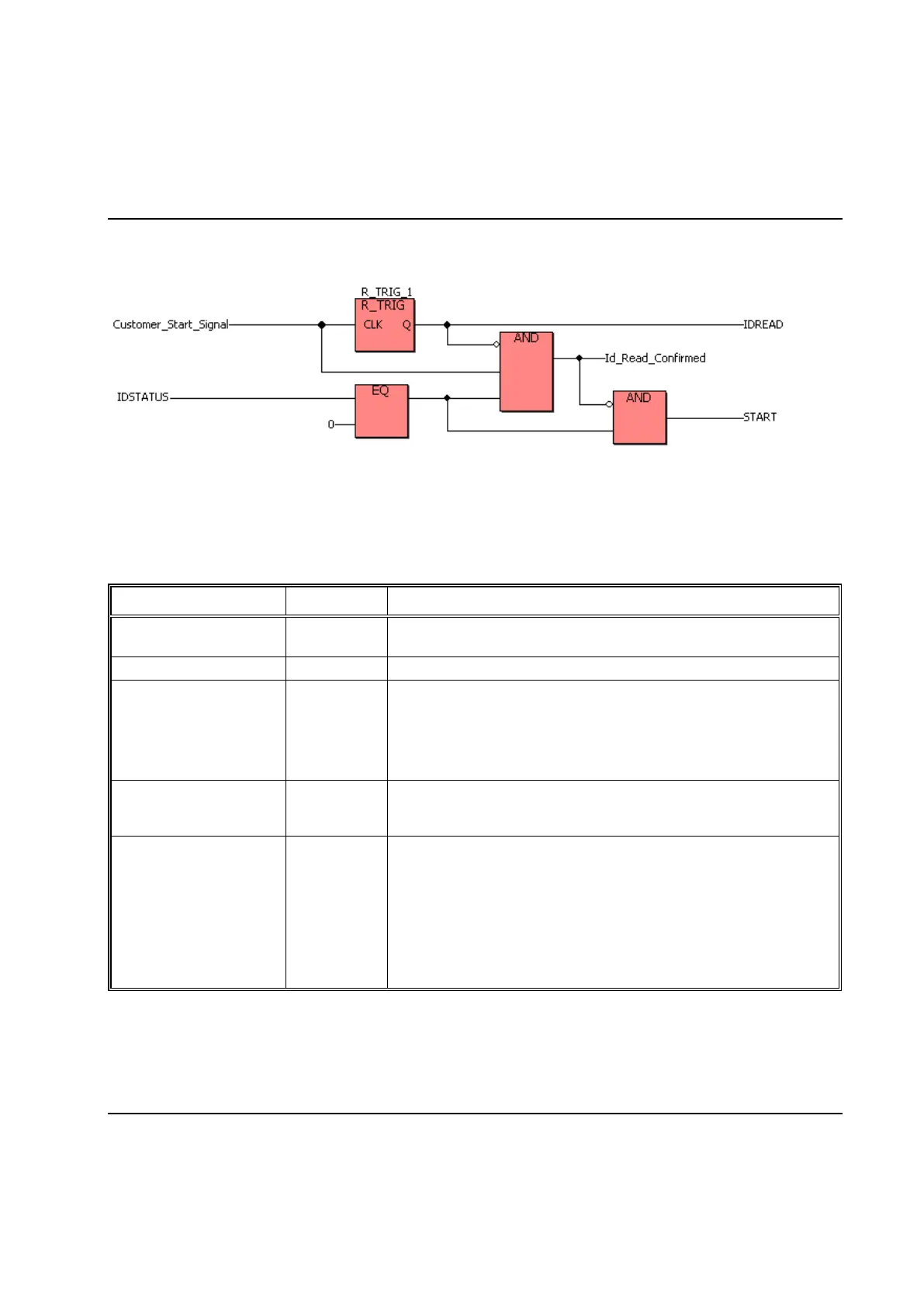

Example: The below code issues an IDREAD order when the signal "Customer_Start_Signal" is set True,

waits for the string to be returned, and then starts the tightening cycle.

5.3.4 Multiple identifier variables

The following input and outputs can be used to control and monitor the Stations Multiple identifiers

function. See chapter: Advanced Station Settings for a description on how it is configured and works.

Inputs:

IDTYPE_1_STR ...

IDTYPE_6_STR

The value of the last accepted string for the respective Identifier

Type. Cleared when on a positive edge of START.

Code generated by the Conversion table defined for Identifier Type 1.

Work Order State. A number between 0 and 4 indicating the latest

accepted item in the Work Order list.

One (1) means that the first Work Order condition is met, two (2) that

the second one was accepted, and so on.

Set zero (0) when the Work Order sequence is reset.

Work Order Complete. Set True when all Types of the Work Order

are accepted. Set False when a cycle is started or if the Work Order

sequence is restarted.

IDTYPE_1_STS...

IDTYPE_6_STS

Status of the read operation of the ID device used as source for the

respective Identifier Type:

0: Idle and OK

1: Idle and NOK

2: Busy – waiting for the device to respond

After issuing an IDTYPE_x_RD you should wait one PLC scan before

evaluating IDTYPE_x_STS.

Loading...

Loading...