Specification

9836 3521 01 623

9 Specification

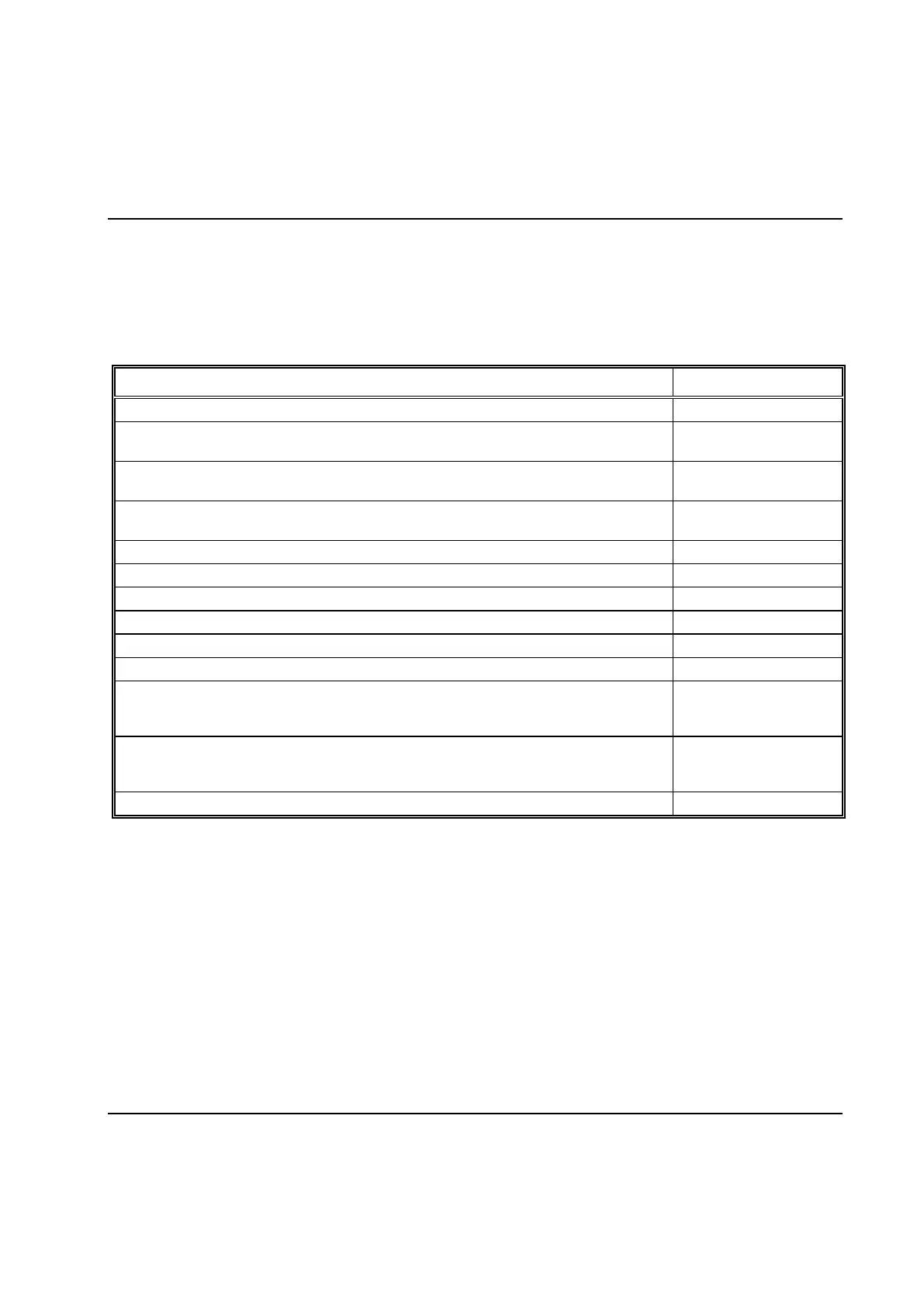

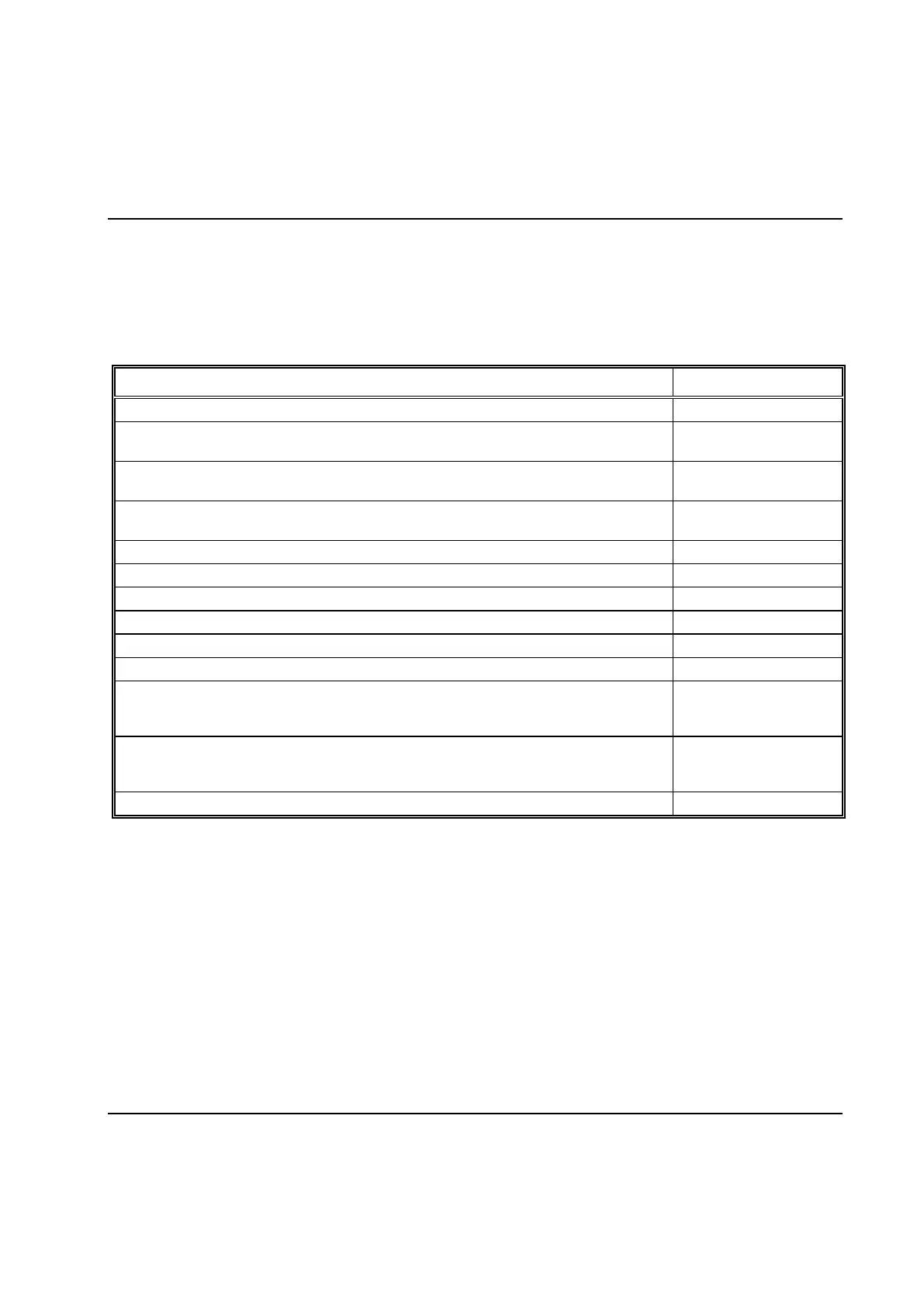

9.1 Specification

This part is the specification of the system. It describes general performances of a complete system:

Max. time from start signal until all spindles are running

Max. time from last spindle stops a step until all are running in the next step:

50 msec. + monitoring

time.

Max. time from last spindle stops last step until OK/NOK status on digital output, per

spindle and total:

0.1 sec. + monitoring

time.

0.5 sec at limited data

reporting.

Delays in set values to servo

Maximum time for a loop in the PLC program

Maximum number of cycle data stored in the system

Depends on number of

bolts and variables

included.

Traces per spindle. Each trace with 2000 values for angle, torque and current.

Up to 300 (depends on

length of trace and curve

form)

Max time to change a device

The Performance values can be seen as a realistic estimate of performance for the finalized system, but

the design of the system is focused on reaching the Target values.

Traces will be stored in two circular buffers with equal size, one for OK cycles, the other for NOK cycles. A

new trace will overwrite the oldest stored trace, independent of tightening program.

Loading...

Loading...