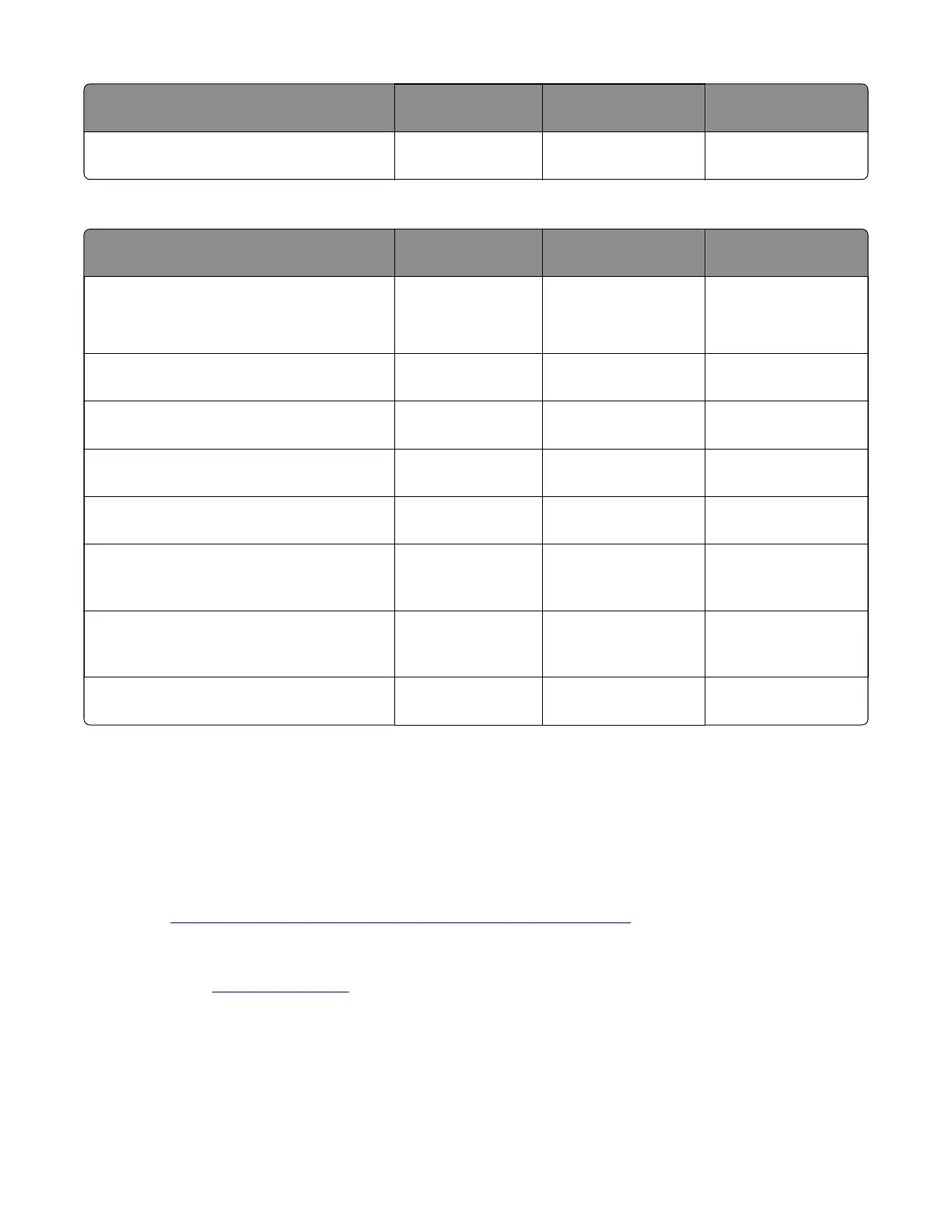

PART/ITEM EVERY SERVICE

CALL

EVERY 200K NOTES

Pick tires Inspect, clean if

needed

Inspect, clean if

needed

Check for toner

contamination.

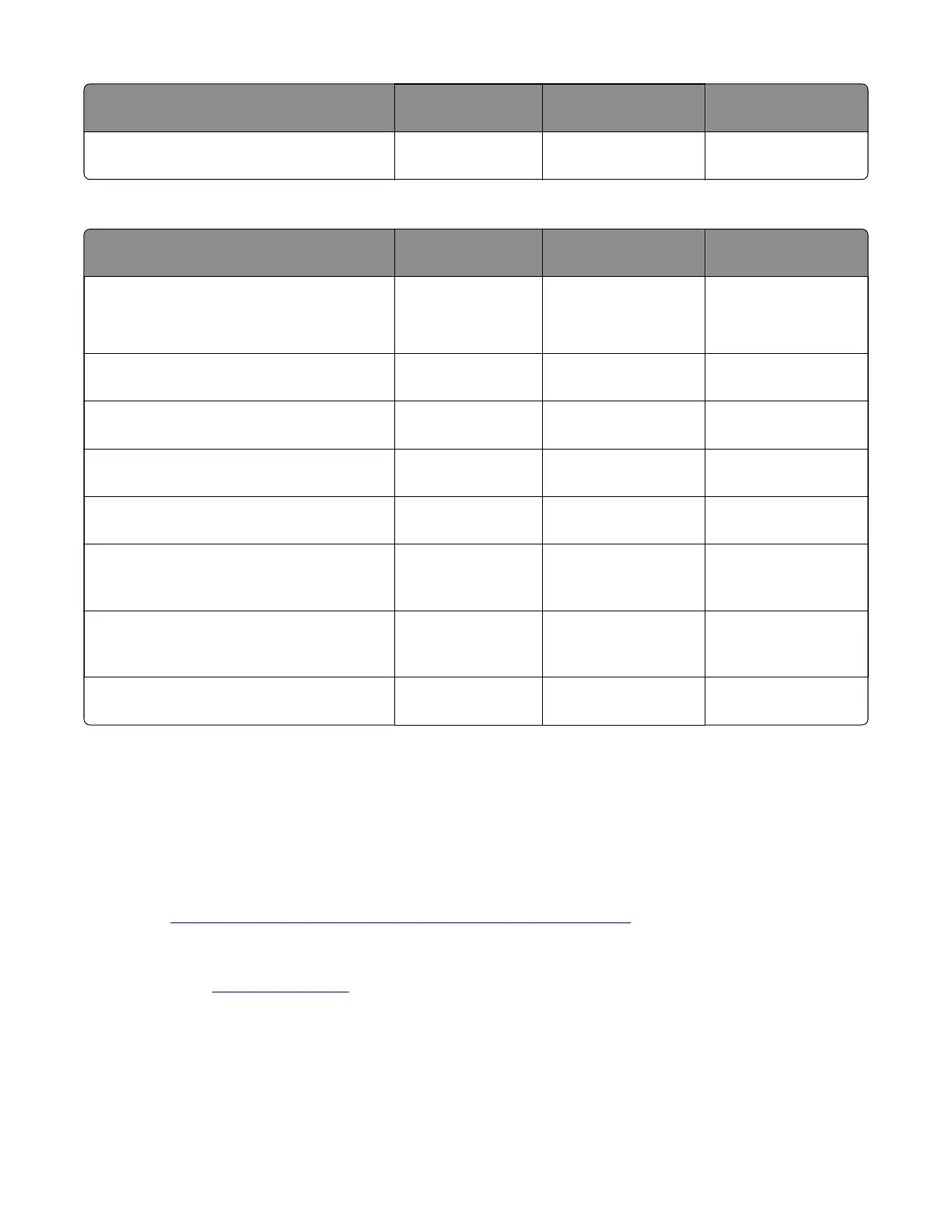

MS82x Inspection guide table

PART/ITEM EVERY SERVICE

CALL

EVERY 225K NOTES

Tray insert

• Width paper guide

• Length paper guide

Inspect Replace Check for correct

positioning.

Separator pad Inspect, clean if

needed

Replace Clean with a damp

cloth.

Tray pick roller Inspect, clean Replace Clean with a damp

cloth.

MPF pick roller Inspect, clean Inspect, clean Clean with a damp

cloth.

Rear door Inspect Inspect Ensure correct

operation and closure.

Duplex paper path Inspect Inspect Check for paper

fragments and

obstructions.

Toner spillage Clean Clean Remove all toner

spillage from the

printer.

Pick tires Inspect, clean if

needed

Inspect, clean if

needed

Check for toner

contamination.

Scheduled maintenance

Fuser maintenance kits

The printer may stop printing when the fuser rated life is reached. At rated fuser life, a Fuser maintenance kit

is required. The correct Fuser maintenance kit must be installed for the type of fuser that is installed in the

printer. See

“Identifying the type of fuser used in the printer” on page 762.

Code levels prior to Base code of LW20.DN4.P231-0 and Engine code of FDN.DN.E410-0 set the 80.3x error

as a non‑continuable stop. To change the 80.3x error code to a continuable stop, please see technical bulletin

TE523 by visiting

www.lexmark.com. A continuable stop is an error code that will allow the user to continue

using the printer once the error is acknowledged using the control panel.

There are multiple warnings to indicate that the fuser is nearing end of life and that a maintenance kit is required.

4064

Maintenance

758

Loading...

Loading...