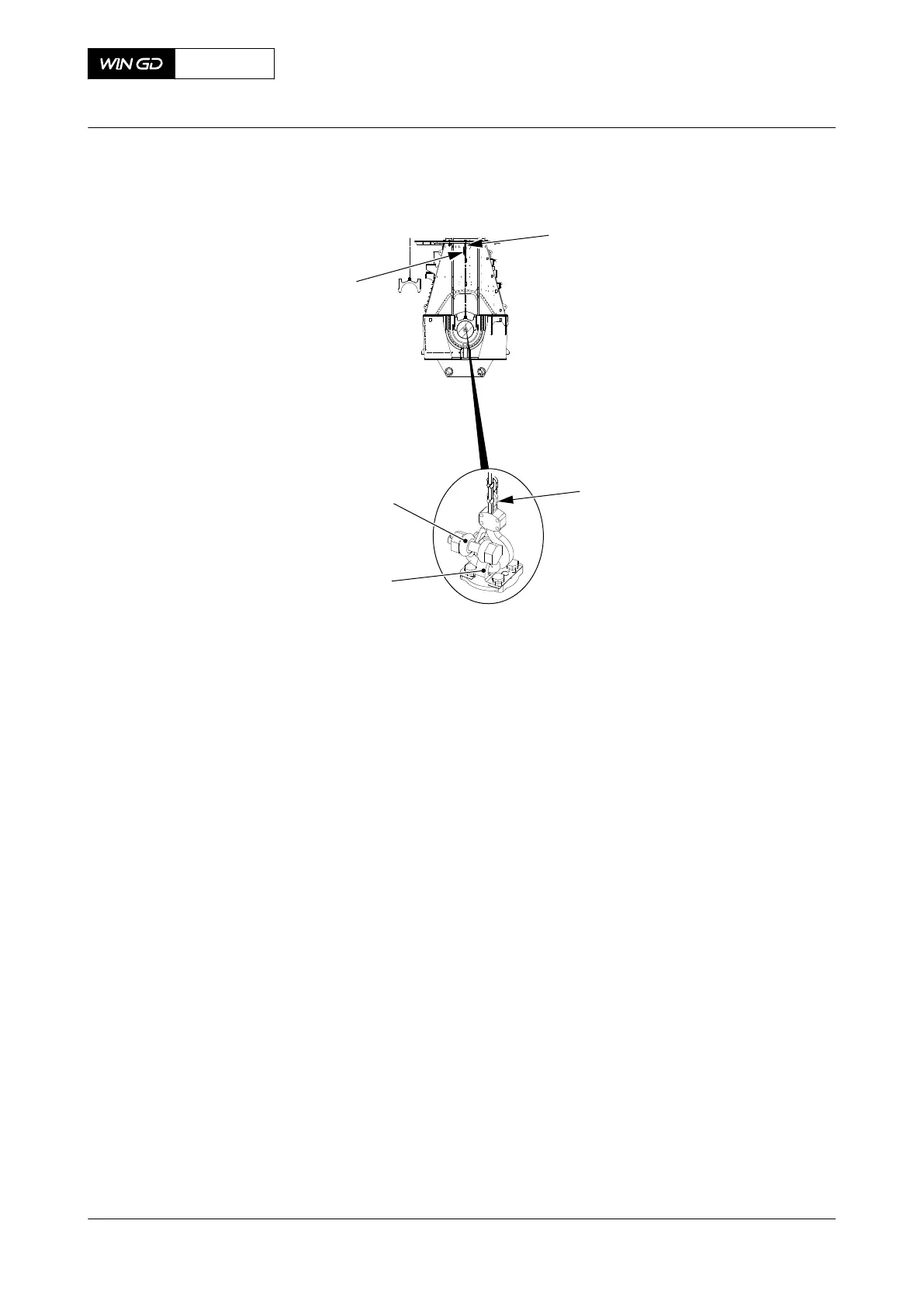

Fig 6-8 Bearing cover - move

26 Clean the pipes (003, Figure 6-9).

27 Install the pipes (003), their gaskets and new tab washers (006).

28 Tighten the screws (005).

29 Lock the screws (005) with the new tab washers (006).

30 Remove all tools and equipment from the work area.

31 Measure the bearing clearance and compare the value measured in section 6.2.1 Main

bearing - remove the cover with the value in section 3.3 Clearances - general.

NOTE: If the clearance is in the limits given, the bearing can be removed and installed

again.

32 After each installation of a new bearing shell, measure the crank deflection, refer to

section 8.1.1 Crankshaft - do a check of the crank deflection.

33 Do a check of the oil supply to the main bearing.

34 If necessary, add more lubricant to the main bearing as follows:

34.1 Remove the blank flange (002) and the screw plug (001).

34.2 Fill the bearing shell with the applicable lubricant.

34.3 Attach the screw plug (001) and the blank flange (002).

X72DF

AA00-1132-00AAA-720A-A

Maintenance Manual Main bearing - install the cover

Winterthur Gas & Diesel Ltd.

- 113 - Issue 002 2020-10