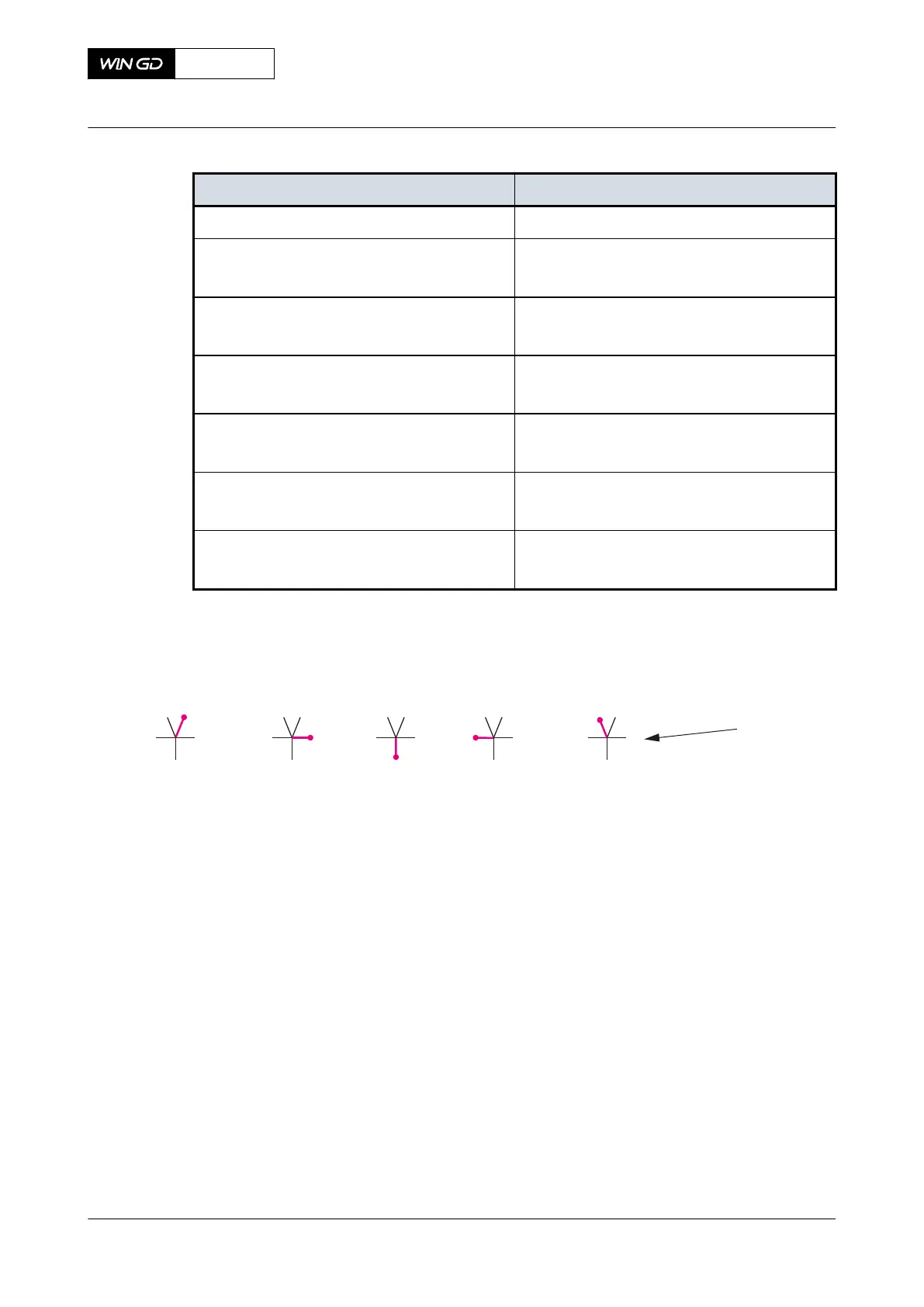

Tab 8-1 Maximum permitted difference in mm

Engine type Difference

X35, X35-B 0.03

X40, X40-B

X40DF

0.03

X52

X52DF

0.04

X62, X62-B

X62DF

0.04

X72, X72-B

X72DF

0.05

X82, X82-B

X82DF

0.06

X92, X92-B

X92DF

0.06

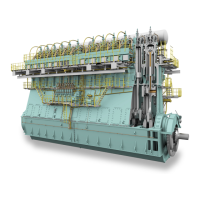

Fig 8-3 Definitions of positions

001

1 2 3 4 5

TDC ES ES BDC FS TDC FS

Legend

001 Dial gauge position

4.11 Do also the visual inspections that follow:

•

Visually do a check of the crank and the bedplate for unwanted material.

•

Visually do a check of the edge for unusual colors.

5 Do Step 4 again for the other cranks.

6 For each crank calculate the vertical deviation d

vert

as follows:

6.1 Calculate the average value d

1’

for position 1 and 5 with the formula

d

1’

= [d

1

+ d

5

] / 2.

6.2 Calculate the vertical deviation d

vert

with the formula d

vert

= d

3

- d

1’

.

7 For each crank calculate the horizontal deviation d

hor

with the formula d

hor

= d

2

- d

4

.

X72DF

AA00-3103-00AAA-360A-A

Maintenance Manual Crankshaft - do a check of the crank deflection

Winterthur Gas & Diesel Ltd.

- 353 - Issue 002 2020-10