PROCEDURE

1 Do this procedure in the conditions that follow:

•

Related to the intervals given from the owner (related to classification societies)

•

Related to the intervals given from WinGD

•

If temperature alarms of bearings occurred

•

If damage of bearings occurred

•

After the main bearing shells are replaced and again after approximately 100

operation hours

•

If the vessel has hit the sea bed.

2 Prepare the vessel and the engine for the measurement as follows:

2.1 Make sure that the items that follow are sufficiently cool:

•

System oil

•

Cooling water

•

Engine

2.2 Make sure that the vessel floats freely in a horizontal position.

NOTE: You must not do this measurement in the dry-dock.

2.3 Get access to the crankshaft of the engine.

3 Record the general data that follow:

•

Load of the engine

•

Temperature of the engine

•

Temperature of the seawater

•

Temperature of the HT water

•

Temperature of the system oil

•

Draught of the vessel (fore side and aft side)

4 Measure the values for the first crank as follows:

4.1 Operate the turning gear to turn the engine in the direction related to Figure 8-2

until the crank is in the BDC position.

4.2 Continue to operate the turning gear in the same direction until the punch marks

are freely accessible (position 1 in Figure 8-2).

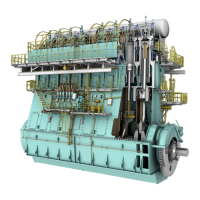

4.3 Put the dial gauge (002, Figure 8-1) next to the connecting rod in the center

punch marks (001). Make sure that the dial gauge (002) goes into the center

punch marks (001).

Fig 8-1 Dial gauge position

4.4 Turn the rod of the dial gauge (002) to apply tension.

4.5 Set the dial gauge (002) to zero.

X72DF

AA00-3103-00AAA-360A-A

Maintenance Manual Crankshaft - do a check of the crank deflection

Winterthur Gas & Diesel Ltd.

- 351 - Issue 002 2020-10