PROCEDURE

1 Attach the eye bolt (001, Figure 7-62) to the valve spindle (004).

2 Attach the rope to the eye bolt (001) and the engine room crane.

3 Put a thin layer of engineer’s blue paste on the sealing face of the valve spindle (004).

4 Put the valve spindle (004) in position in the valve guide bush.

5 Put the wooden block (003) on the valve spindle (004).

6 Tap the wooden block (003) with the hammer (002) three or four times.

NOTE: During this step, do not turn the valve spindle (004) because this can cause

the sealing faces to catch.

7 Use the feeler gauge to do a check of the clearance X between the sealing faces of the

valve spindle (004) and valve seat (005), refer to Table 7-2 - Exhaust valve, clearance X.

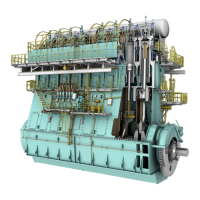

Tab 7-2 Exhaust valve, clearance X

Engine type Clearance X [mm]

X35, X35-B 0.005 to 0.020

X40, X40-B

X40DF

0.005 to 0.020

X52

X52DF

0.033 to 0.062

X62, X62-B

X62DF

0.054 to 0.070

X72, X72-B

X72DF

0.054 to 0.070

X82, X82-B

X82DF

0.120 to 0.150

X92, X92-B

X92DF

0.120 to 0.150

8 Remove the valve spindle (004) from the guide bush.

9 Do a check of the engineer’s blue paste. The paste must only show on the inner part of

the full circumference of the valve spindle.

X72DF

AA00-2751-01AAA-360A-A

Maintenance Manual Exhaust valve - do a check of the seat

Winterthur Gas & Diesel Ltd.

- 305 - Issue 002 2020-10