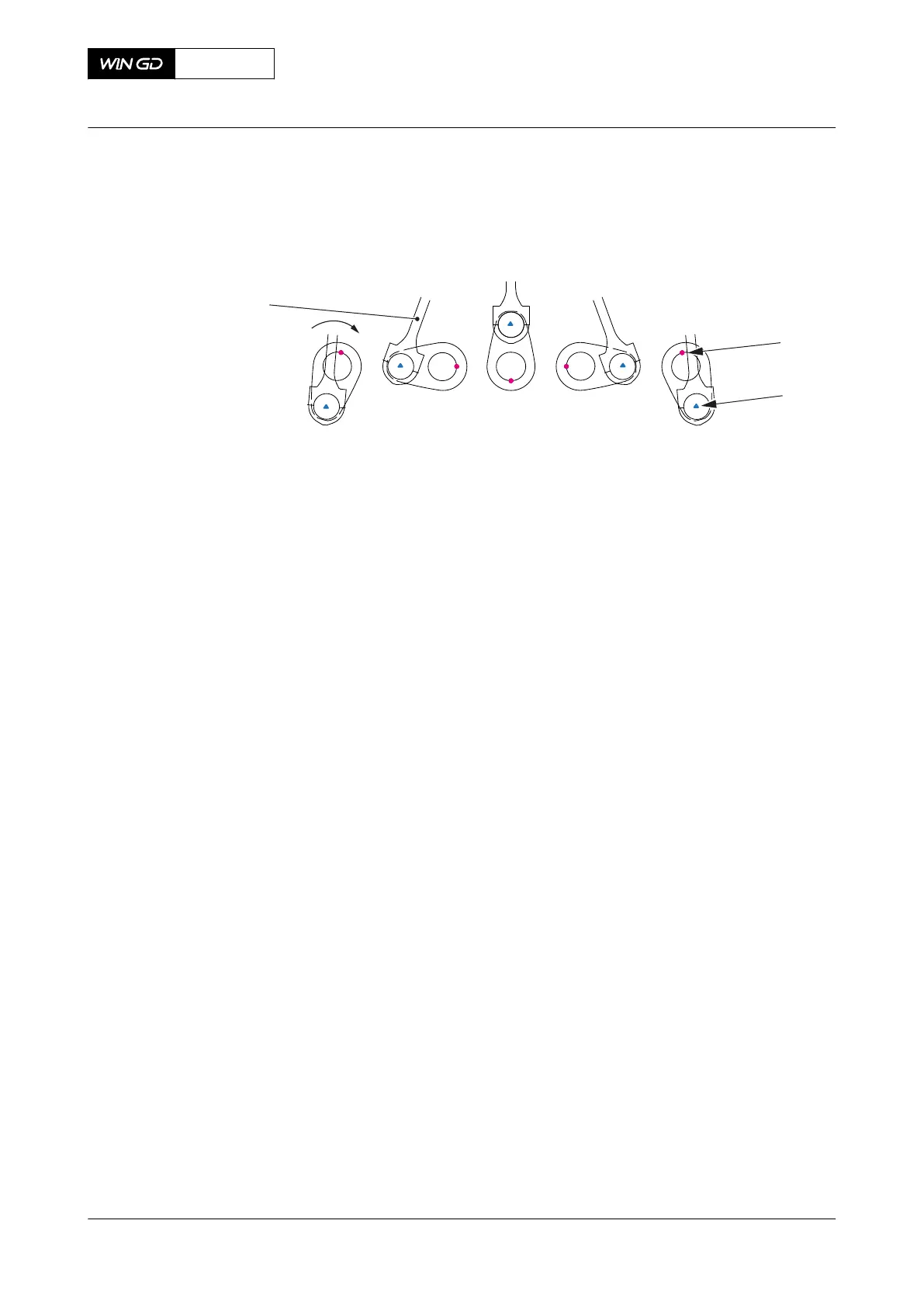

4.6 Operate the turning gear in the same direction to move the crank to each

position of the dial gauge (001, Figure 8-2).

Fig 8-2 Crank positions for clockwise direction

Legend

001 Dial gauge position 003 Connecting rod

002 Crank pin position

NOTE: For counterclockwise rotation, start at position 5.

4.7 For cranks n to n-1 or n-2 (related to the number of cylinders of the engine)

operate the turning gear in the opposite direction a short time to release

pressure between pinion and flywheel.

4.8 At each position, record the indication on the dial gauge. For the last position

make sure that the connecting rod (003) does not touch the dial gauge.

4.9 At position 3 also visually check the clearance of the connecting rod bearing.

4.10 If the difference between positions 1 and 5 is more than the value related to

Table 8-1 - Maximum permitted difference in mm, you must do the measurement

again.

NOTE: For the definitions for positions 1 to 5 refer to Figure 8-3.

X72DF

AA00-3103-00AAA-360A-A

Maintenance Manual Crankshaft - do a check of the crank deflection

Winterthur Gas & Diesel Ltd.

- 352 - Issue 002 2020-10