PROCEDURE

CAUTION

Damage Hazard: The surfaces of the cylinder liner and the nozzle tip make a metallic

seal. The seat angles in the cylinder liner and on the nozzle tip are different. Do not use a

gasket between the cylinder liner and the nozzle tip. This could cause damage to the

equipment.

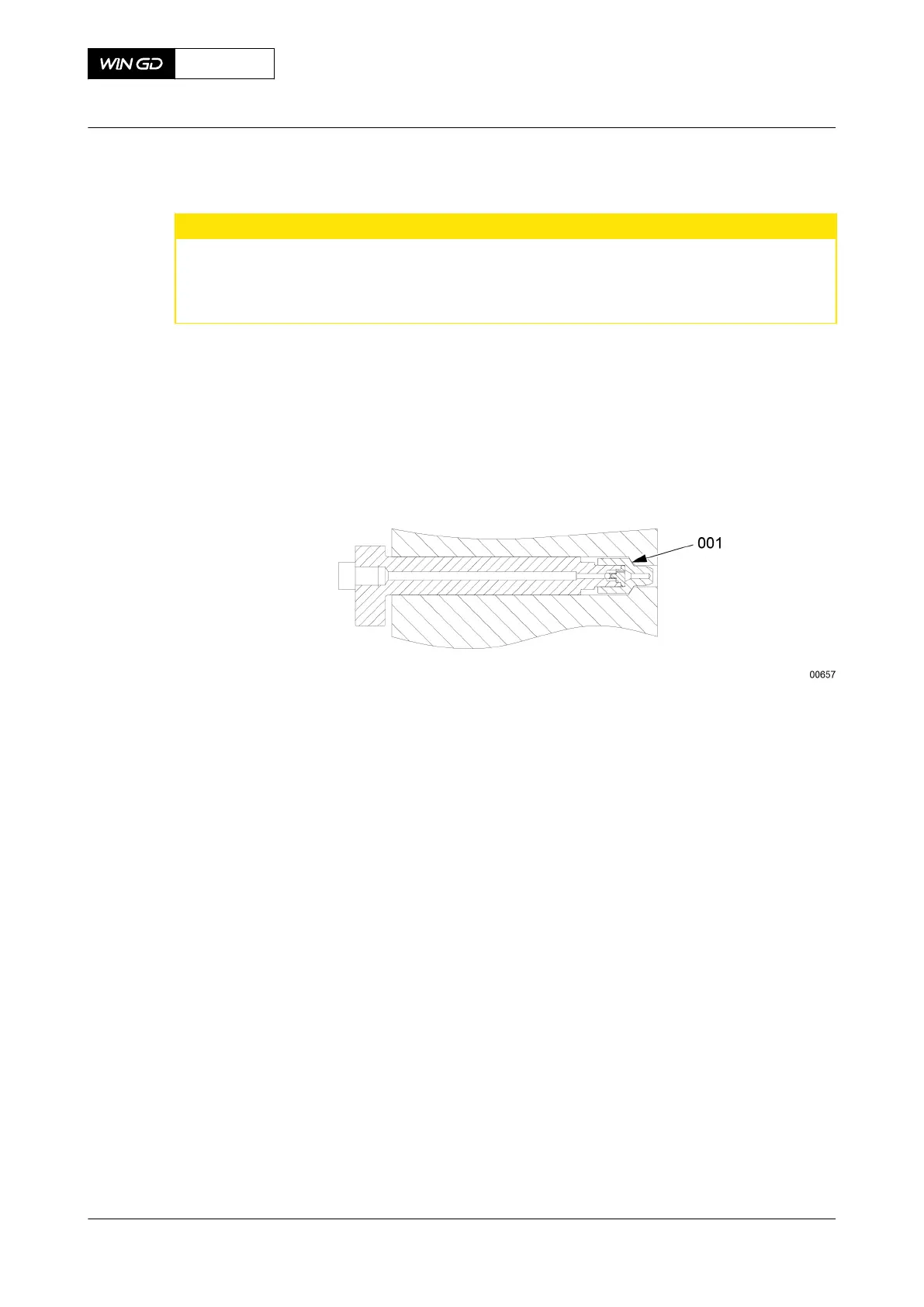

1 Make sure that the sealing surfaces (001, Figure 7-15) are clean and have no damage.

NOTE: If a component of the lubricating quill is defective, you must replace all

components of the lubricating quill.

Fig 7-15 Sealing surface

2 Apply oil to the threads of the screws (004, Figure 7-16).

3 Attach the lubricating quill (003) to the cylinder liner (001) with the screws (004).

4 Torque the screws (004) to the related value, refer to section 16.1 Tightening

instructions.

5 Remove the plugs from the pipe (002).

6 Attach the pipe (002) to the lubricating quill (003).

7 Tighten the nuts (005) of the unions.

X72DF

AA00-2138-00AAA-720A-A

Maintenance Manual Lubricating quill - install

Winterthur Gas & Diesel Ltd.

- 199 - Issue 002 2020-10