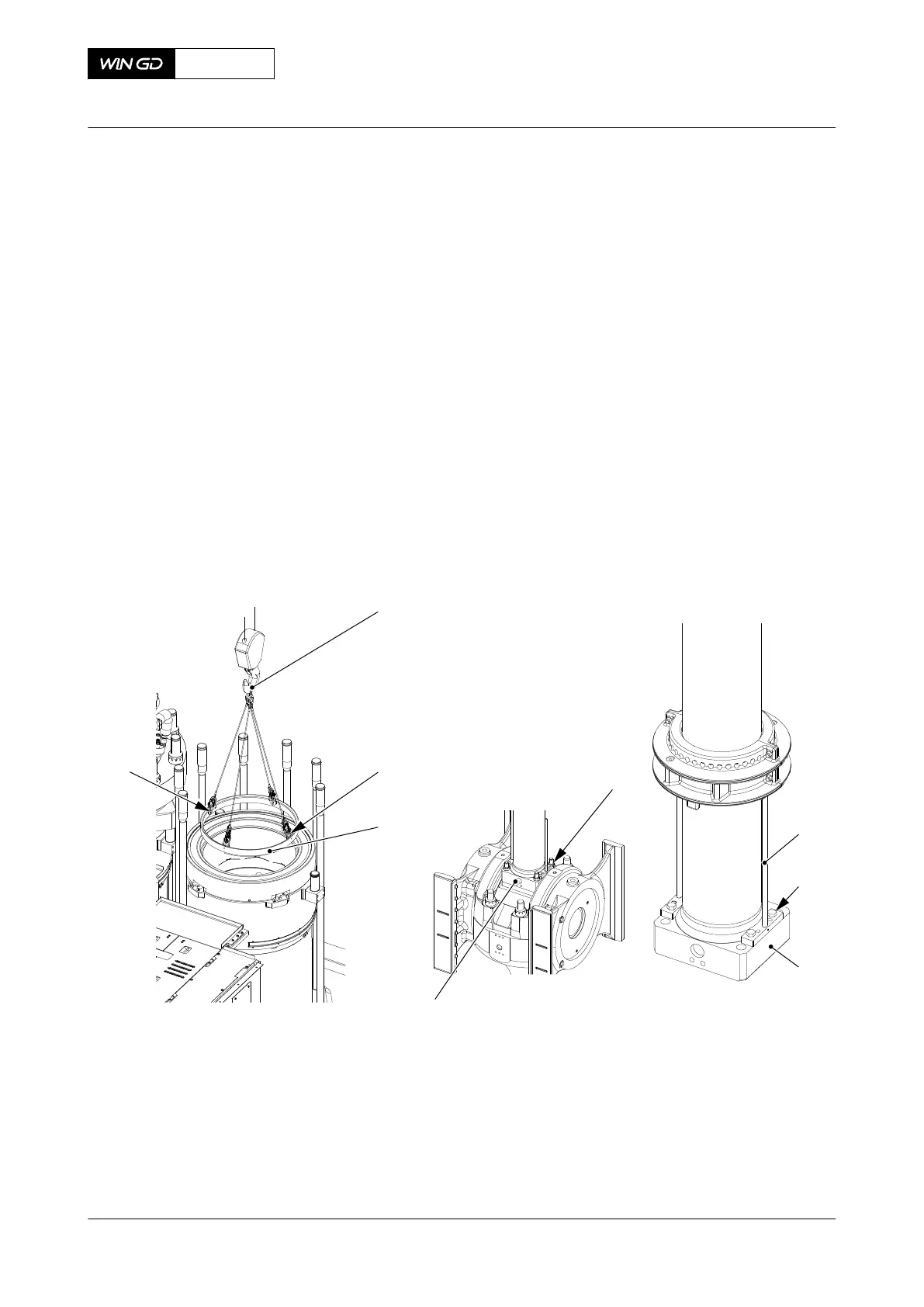

PROCEDURE

1 Attach the four plates (002, Figure 8-68) to the antipolishing ring (003) with the four

screws (004).

2 Connect the engine room crane to the lifting tool (001).

3 Attach the tool 94209 to the antipolishing ring (003).

4 Attach the lifting tool (001) to the tool 94209.

5 Remove the antipolishing ring (003).

6 Look at the area where the piston stroke ends. If there is a wear edge, refer to section

7.1.4 Cylinder liner - grind.

7 Operate the turning gear to move the crank to BDC.

8 Remove the round nuts (005) from the piston rod foot (006), refer to section 4.3 Loosen

a round nut with a pre-tensioner.

9 Attach the two distance holders (007) to the piston rod foot (006) with the screws (008).

10 Remove the knee lever from the crosshead connection.

11 Attach the knee lever in a save position.

Fig 8-68 Piston - Preparation

001

002

003

004

005

006

007

008

006

00779

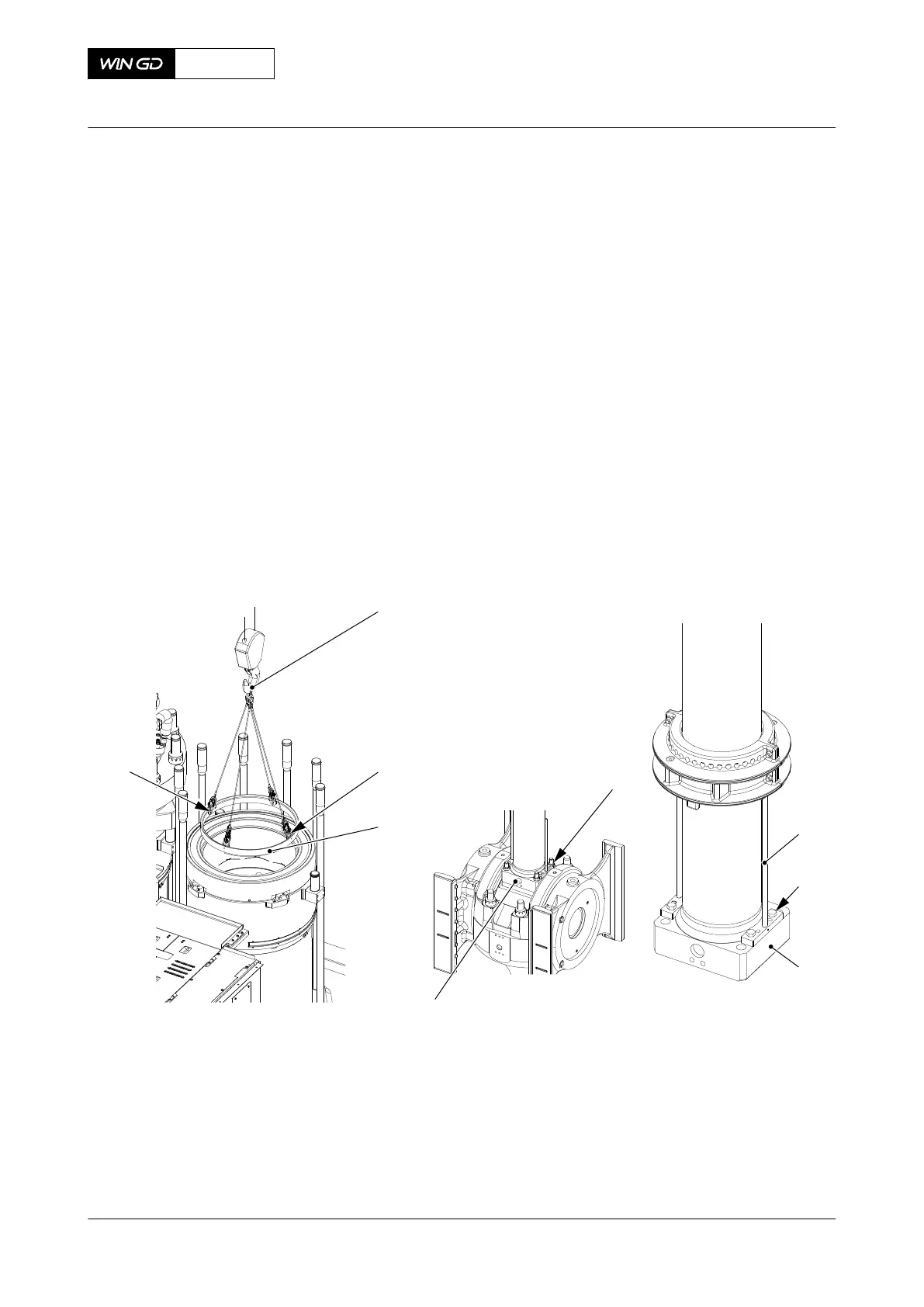

12 Remove the four bolts (002) from the gland box support (001, Figure 8-69).

13 Operate the turning gear to move the crosshead up until the distance pieces (005) touch

the gland box.

14 Operate the turning gear to push out the gland box out of the cylinder jacket.

15 Continue to operate the turning gear to move the piston to TDC.

16 Clean the threads of the three holes and the top part of the piston crown.

17 Make sure that the lifting tool 94341 is clean.

18 Remove the six bolts and the three brackets.

X72DF

AA00-3403-00AAA-523A-A

Maintenance Manual Piston - prepare before removal

Winterthur Gas & Diesel Ltd.

- 477 - Issue 002 2020-10

Loading...

Loading...