PROCEDURE

1 Remove all the protection from the sealing faces, the injection valve and the flow limiting

valve.

2 Attach new O-rings to the flanges (002, 006).

3 Apply Never-Seez NSBT to threads of the Allen screws (004 and 008, Figure 13-10).

4 Carefully put the HP injection pipe (001) in position in the injection valve (005) and the

flow limiting valve (003).

5 Torque symmetrically the four Allen screws (004) to the correct value, refer to section

16.1 Tightening instructions.

6 Torque symmetrically the four Allen screws (007) to the correct value, refer to section

16.1 Tightening instructions.

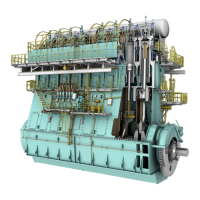

7 Make sure that the distance X between the flange (002, 006) and the end of the pipe

refers to Table 13-3 - Distances X and Y for HP fuel pipe.

Tab 13-3 Distances X and Y for HP fuel pipe

Engine type Distance X [mm]

X52

X52DF

xxx

X62 / -B

X62DF

xxx

X72 / -B

X72DF

5.8

X92 / -B

X92DF

6.0

X72DF

AA00-8733-00AAA-720A-A

Maintenance Manual HP fuel pipe (fuel rail to injection valve) - install

Winterthur Gas & Diesel Ltd.

- 753 - Issue 002 2020-10