PROCEDURE

1 Operate the turning gear to move the roller of the related fuel pump to its highest

position (TDC).

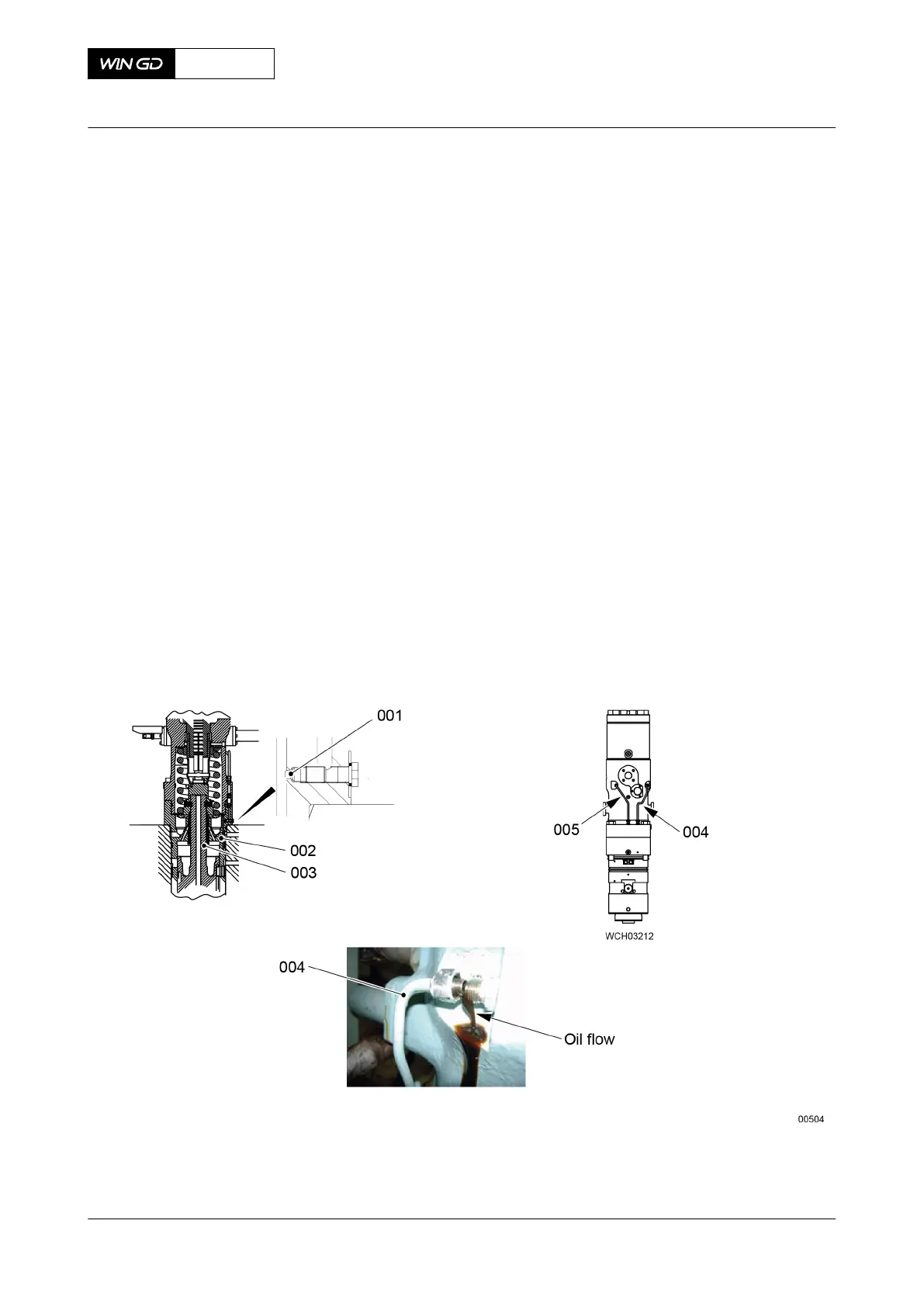

NOTE: The oil flows through the throttle (001, Figure 10-19) to the bottom housing

(002) and the guide piston (003).

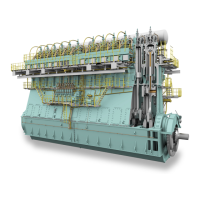

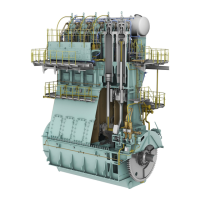

2 Remove the oil drain pipe (004) from the fuel pump.

3 Set to ON the servo oil service pump.

4 After one minute, make sure that you can see the oil flow as shown.

5 If the oil does not flow as shown, read the data in Technical Bulletin RT-180.

6 Make sure that the oil flows in the inlet pipe (005).

NOTE: If the oil in the inlet pipe (005) does not flow freely, it is possible that there are

unwanted particles in the oil supply system. If you find particles, remove them.

7 If there is incorrect oil flow, or no flow through the drain bore do Step 7.1 to Step 7.4:

7.1 If the oil cannot flow freely, flush the bores with WD-40.

7.2 If there is no oil flow, use a heat gun to apply heat to the clogged drain bore.

7.3 Use a small drill bit to open the bore.

7.4 Remove the particles with a nylon brush.

8 Install all unions and plugs.

9 Connect the oil drain pipe (004) to the fuel pump.

Fig 10-19 Fuel pump - oil flow

X72DF

AA00-5556-00AAA-320A-A

Maintenance Manual Fuel pump - do a test of the operation

Winterthur Gas & Diesel Ltd.

- 573 - Issue 002 2020-10