27.4 Ethernet Connection

27.4.11 Precautions

27 - 83

25

BAR CODE READER

CONNECTION

26

PRINTER CONNECTION

27

CNC CONNECTION

28

MULTI-CHANNEL

FUNCTION

29

FA TRANSPARENT

FUNCTION

30

MULTIPLE-GT11

CONNECTION FUNCTION

31

GATEWAY FUNCTION INDEX

27.4.11 Precautions

1 Via network system

GOT with Ethernet communication cannot access the CNCs in another network via the CNC (network

module, Ethernet module, etc.).

2 When connecting to multiple GOTs

When connecting two or more GOTs in the Ethernet network, set each "PC No." to the GOT.

Section 27.4.5 Setting communication interface (Communication settings)

3 When connecting to the multiple network equipments (including GOT) in a segment

By increasing the network load, the transmission speed between the GOT and CNC may be reduced.

The following actions may improve the communication performance.

• Using a switching hub

• More high speed by 100BASE-TX (100Mbps)

• Reduction of the monitoring points on GOT

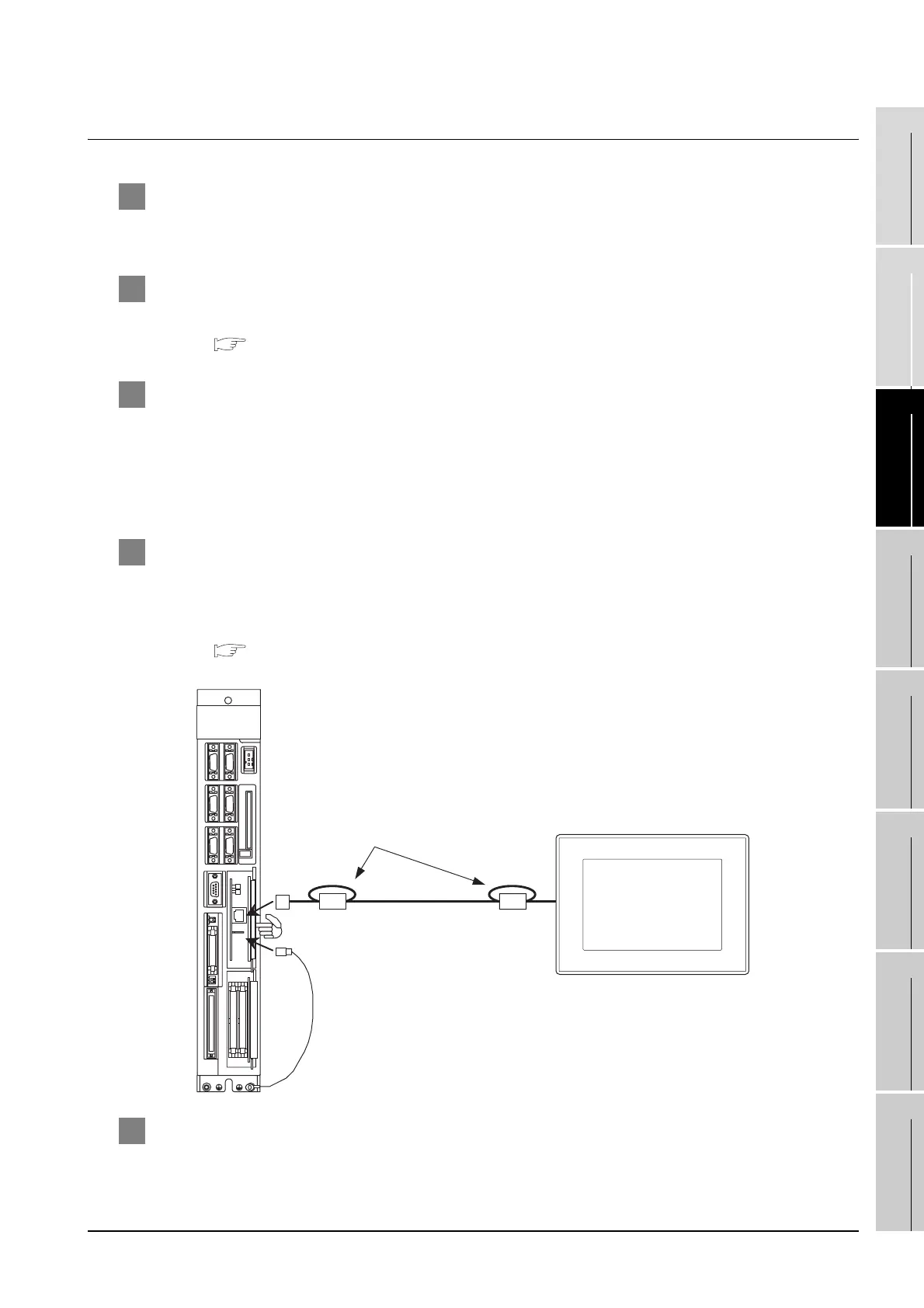

4 Ethernet cable connection

Ethernet cable is so susceptible to noise that you should wire power cables and electric supply cables

separately. And you need to attach a ferrite core (attachment) on the control unit side.

For details of the Ethernet cable connection, refer to the following

MELDAS C6/C64 NETWORK MANUAL BNP-B2373 IX Connection Function with GOT

5 Version of CNC

For MELDAS C6/C64, use NC system software version D0 or later.

LED1

1 turn

Ferrite core

Ferrite core

Ethernet

GOT

FG cable for Ethernet

Loading...

Loading...