#

Turn thering of cargotie-down ring B untilit

is parallel to thelongitudinal axis of cargo tie-

down ring C.

#

Holdcargo tie-down ring C between the

indexfinger andmiddlefinger andplace your

thumb through thering of cargotie-down ring

B and ontothe centralpressurepoint.

#

Use your thumb to push thelocking pin down

as farasitwillgo.

#

Push cargo tie-down ring C nearthe load

through thenotches on rack rail 2 and move

it approximately 0.5 in (12mm).

#

Remove your thumb from thepressurepoint

and slide cargo tie-down ring C untilit

engages.

#

Turn thering of cargotie-down ring B untilit

is perpendicular to thelongitudinal axis of

cargo tie-down ring C.

Cargo tie-down ring C is secured.

Removing cargo tie down rings

#

Turn thering of cargotie-down ring B untilit

is parallel to thelongitudinal axis of cargo tie-

down ring C.

#

Grip cargo tie-down ring C as described

above underinstalling and use your thumb to

push thelocking pin down as farasitwillgo.

#

Slide cargo tie-down ring C and pull it down

and outthrough thenotches of rack rail 2.

Attachingthe headlashing

&

WARNING Risk of injury due to incor‐

rectly securedloads

When thehooksonthe head lashing are

attached to theringsofthe sliders, theslid‐

erscould come loose. The load maycome

loose, fall down and injurepeople, for

instance when they enter or load and unload

thecargo compartment.

#

Onlyattach thehooksonthe head lash‐

ing to theringsofthe cargo tie-down

rings.

%

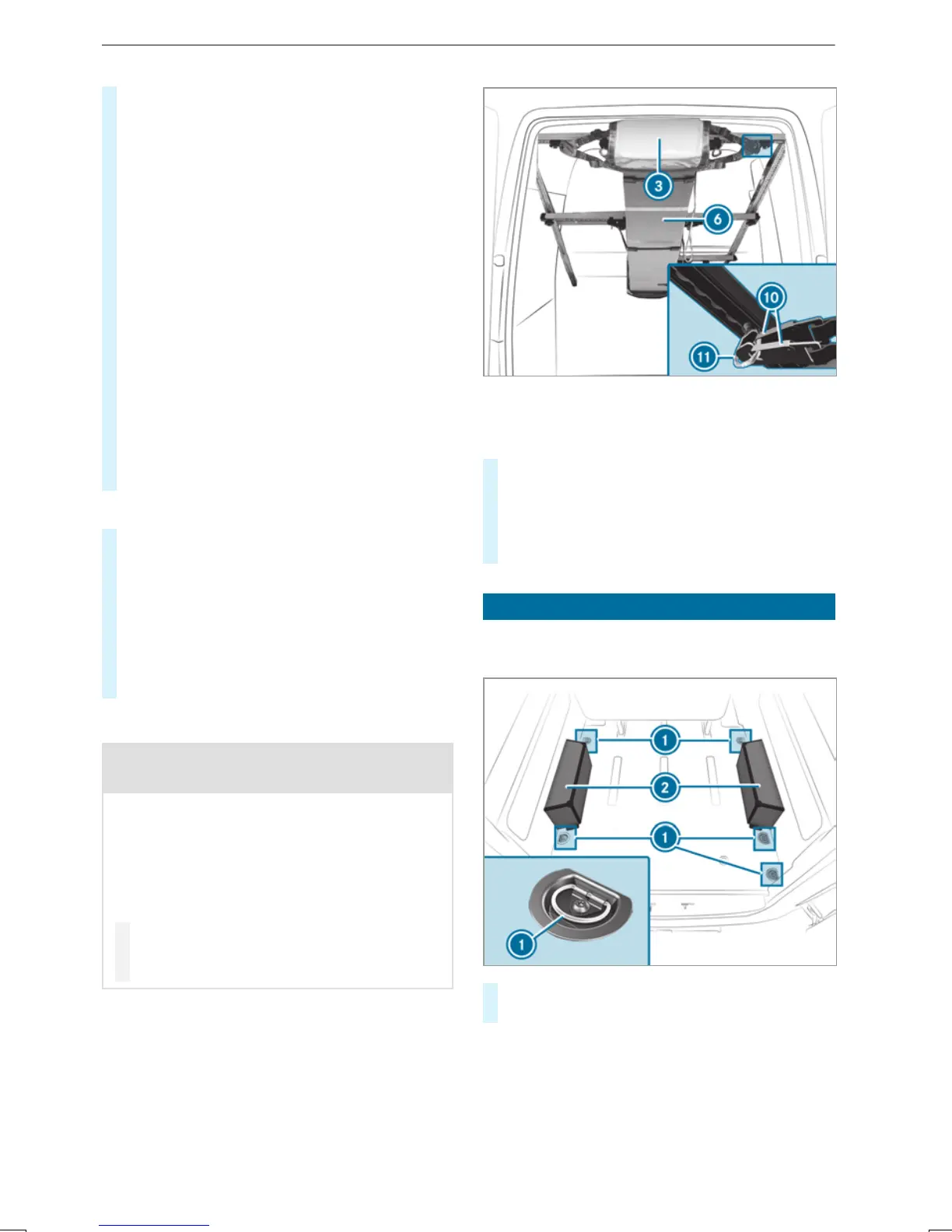

The hooks on head lashing 3 mayonlybe

attached to theringsofcargo tie down rings

B.

#

Checkthat theload is seated securely.

#

To attachthe headlashing: tensionhead

lashing 3 at both ends of load 6 and

attachtwo hooks A of thehead lashing to

theringsofcargo tie down rings B.

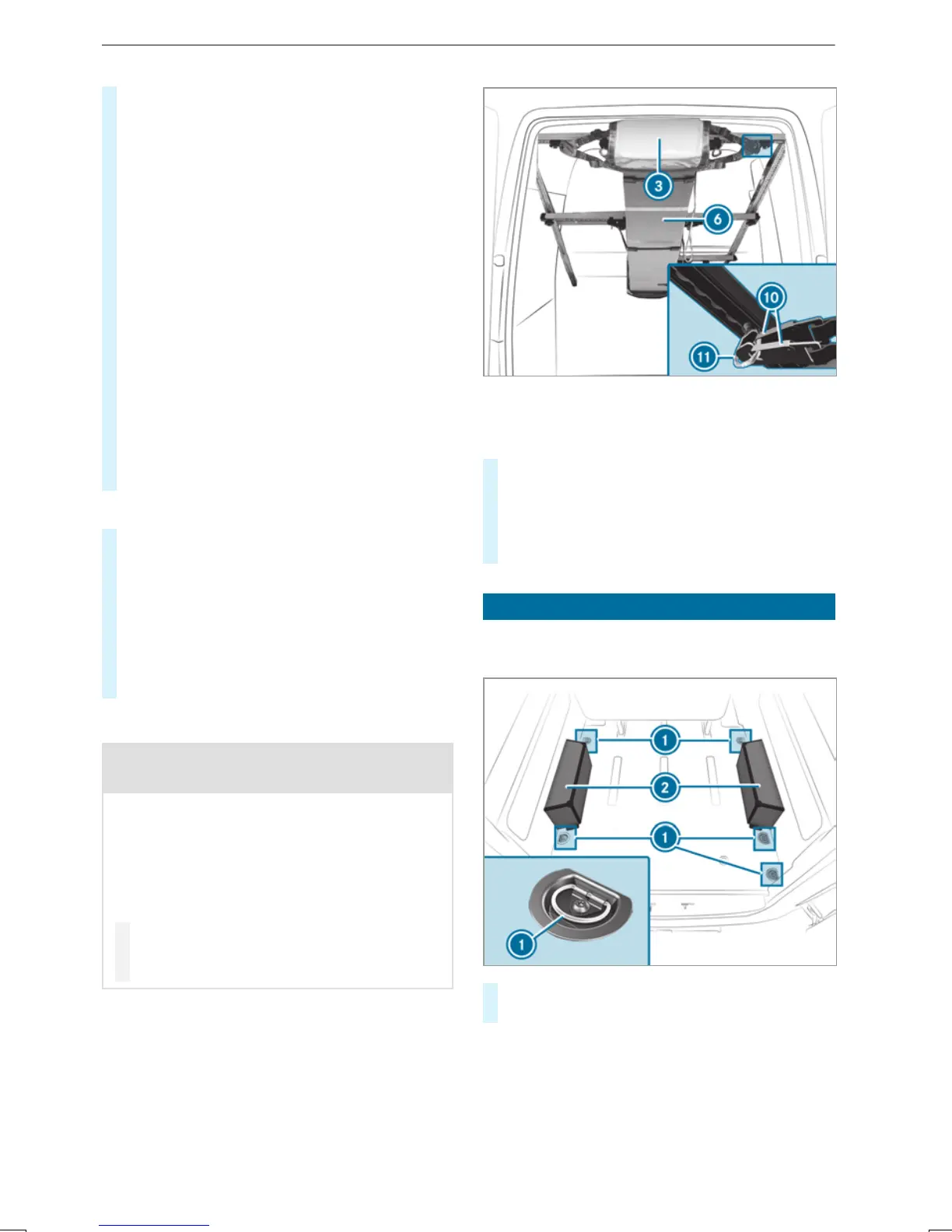

Placing aloadonthe wheel arch

Complywiththe important safety notesunder

"Notesonloading" (/ page73).

#

Place theobjectsonwheel arch 2 and lash

them using tie-down eyes 1(/ page259).

%

Awheel arch maybesubjected to aload of

330lb(150kg).

Transporting

263

Loading...

Loading...