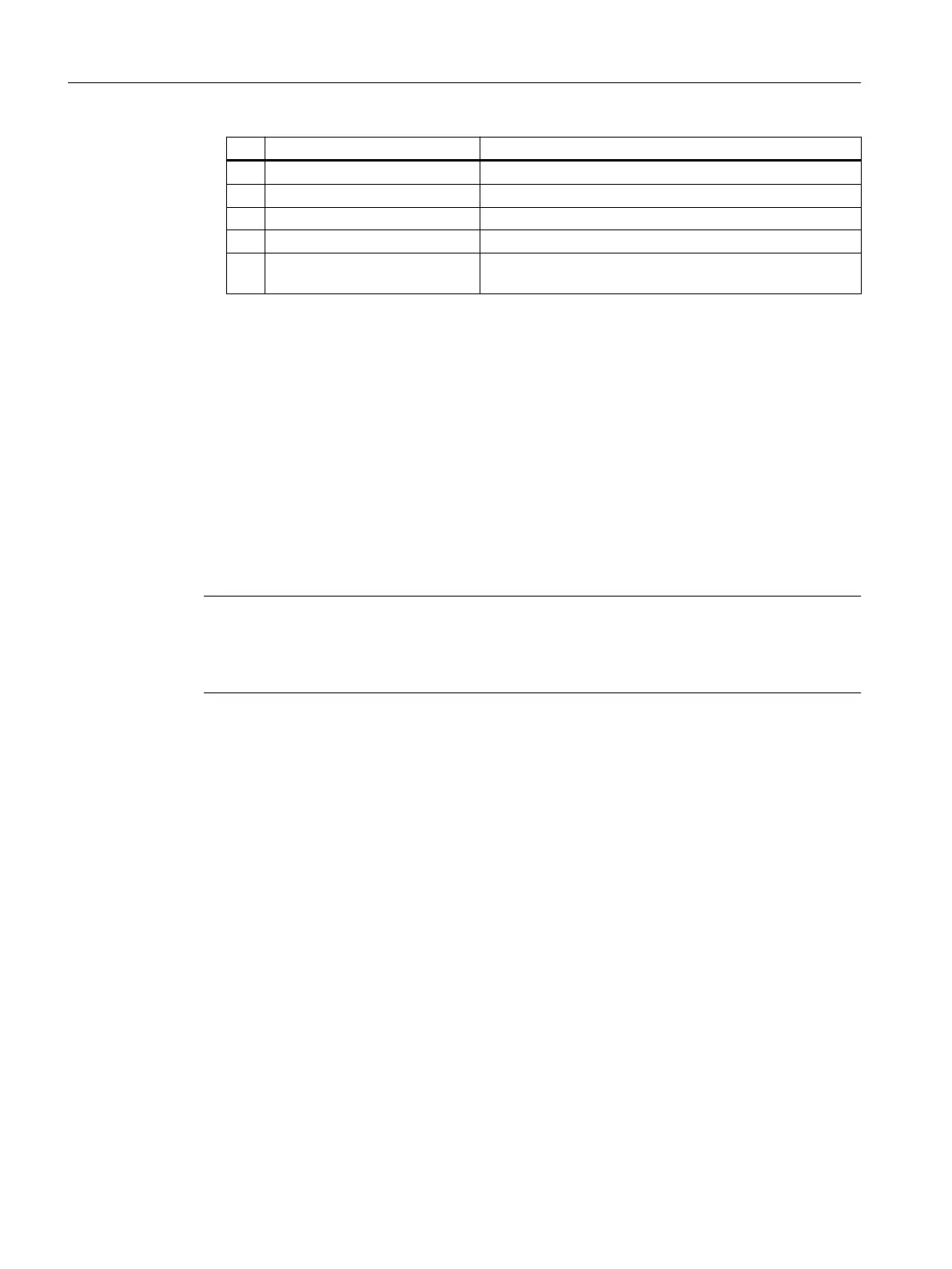

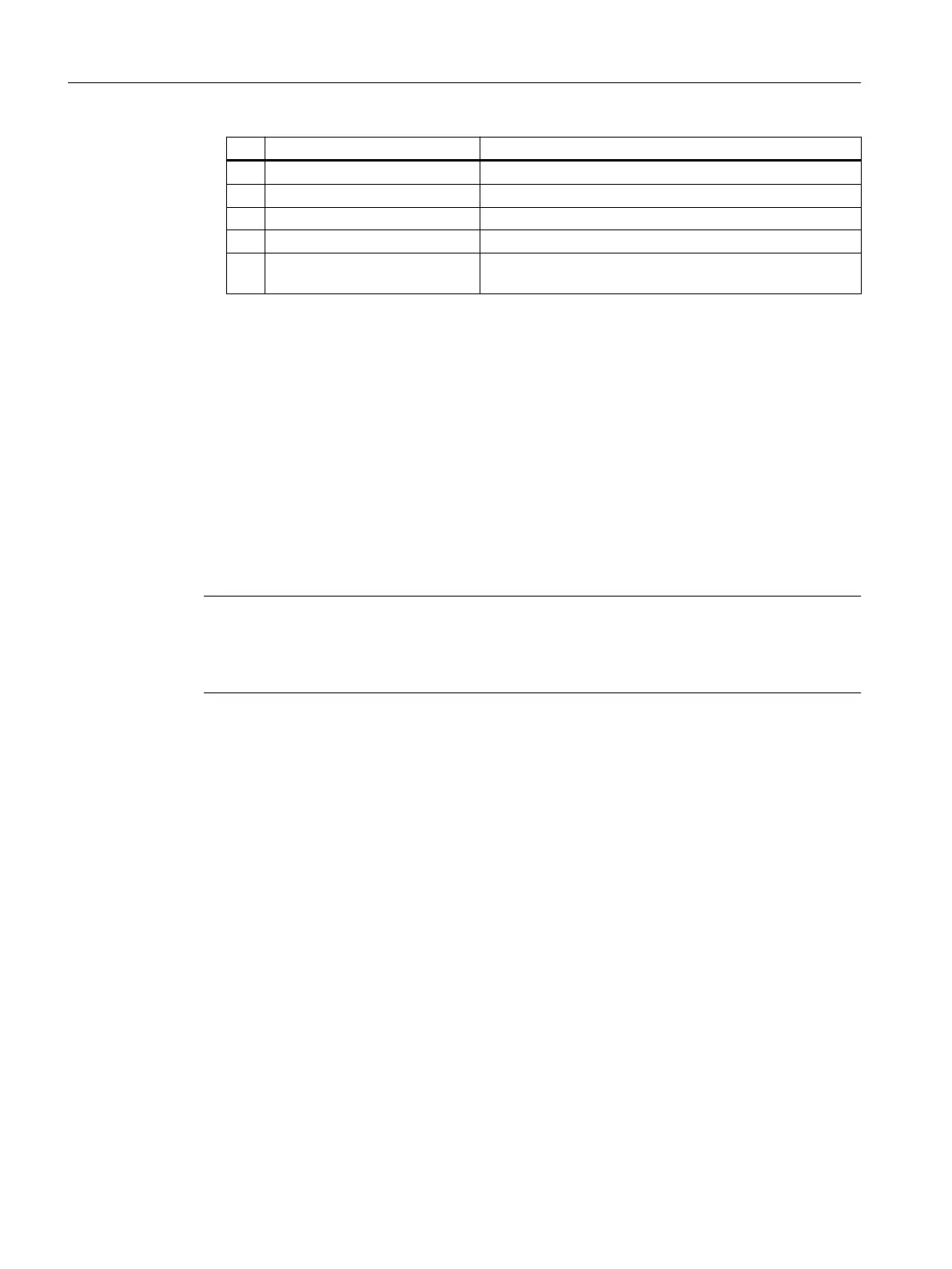

No. Fault cause Remedial measures

N Rotor out of true, shaft bent Consult the manufacturer

O Poor alignment Align motor set, check coupling

P Coupled machine not balanced Re-balance coupled machine

Q Shocks from coupled machine Check coupled machine

R Fault originating from the gear‐

bo

x

Adjus

t or repair the gearbox

If the fault still cannot be resolved after taking the measures stated above, contact the

manufacturer or the Siemens Service Center.

13.2.1 Replacing the motor bearings

Description

Motor bearings are wearing parts. They must be replaced after a dened number of operating

hours. At medium loads, the motor bearings last approximately 20000 hours.

Especially favorable ambient conditions, such as low average speed, low radial force

(transverse force) and vibration load, can prolong the interval until motor replacement.

Note

Premature bear

ing and motor replacement

Harsh operating conditions (for example, continuous operation at n

max

, high vibration or shock

loads, frequent reversing duty) reduce the bearing or motor replacement interval by up to 50%.

The procedure for replacing the motor bearing depends on the size of the motor.

Replacement of the mot

or bearings is only intended for high inertia motors. For low or

medium inertia motors, it is not possible to replace the motor bearings. Replace the motors

in their entirety.

The maintenance and repair of the motor can be performed in authorized Siemens Service

Centers all over the world. Contact your personal Siemens representative if you need this

service.

Corrective maintenance

13.2Service and maintenance for the motor

SINAMICS S200 PROFINET servo drive system with SIMOTICS S-1FL2

602 Operating Instructions, 11/2023, FW V6.3, A5E51646752B AB

Loading...

Loading...