HINT:

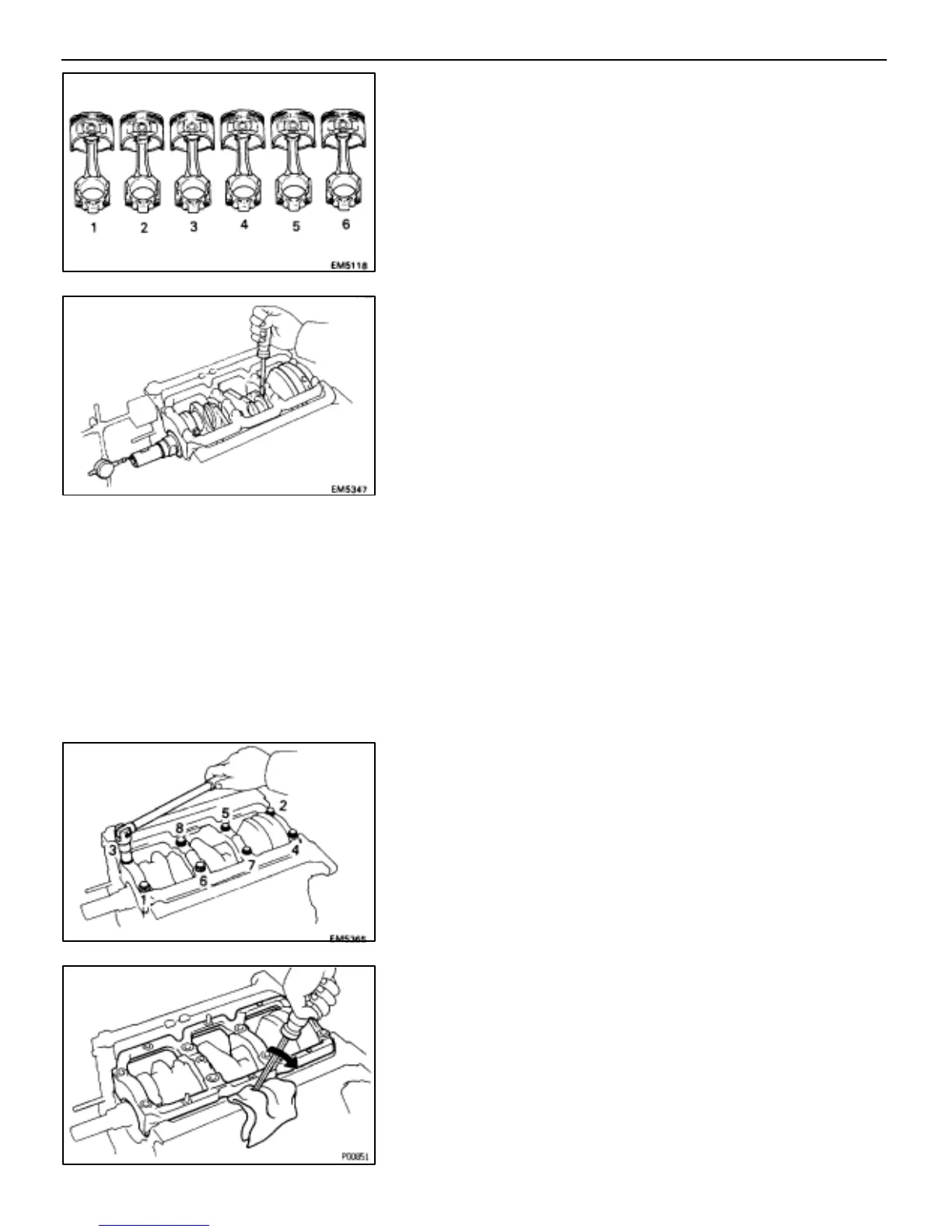

•Keep the bearings, connecting rod and cap together.

•Arrange the piston and connecting rod assemblies in correct

order.

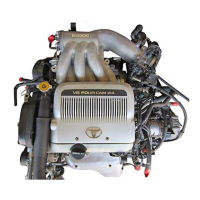

5. CHECK CRANKSHAFT THRUST CLEARANCE

Using a dial indicator, measure the thrust clearance while pry-

ing the crankshaft back and forth with a screwdriver.

Standard thrust clearance:

0.020–0.220 mm (0.0008–0.0087 in.)

Maximum thrust clearance:

0.30 mm (0.0118 in.)

If the thrust clearance is greater than maximum, replace the

thrust washers as a set.

Thrust washer thickness:

2.440–2.490 mm (0.0961–0.0980 in.)

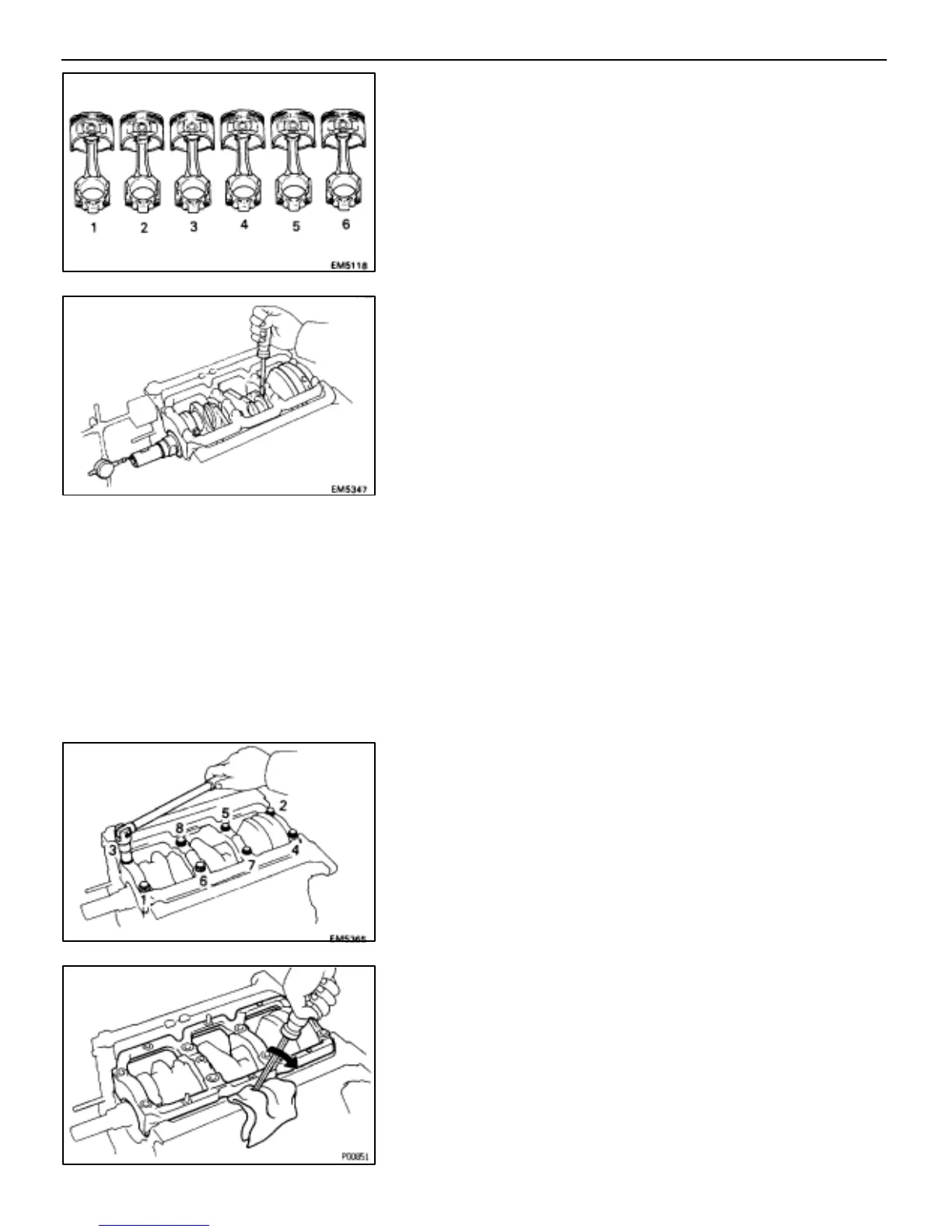

6. REMOVE MAIN BEARING CAP AND CHECK OIL

CLEARANCE

(a) Uniformly loosen and remove the main bearing cap bolts in

several passes, in the sequence shown.

(b) Using a screwdriver, pry up the main bearing cap, and

remove the main bearing cap, lower main bearings and lower

thrust washers (No.2 journal position of main bearing cap

only).

HINT: Keep the lower main bearings and lower thrust wash-

ers together with the main bearing cap.

(c) Lift out the crankshaft.

HINT: Keep the upper main bearings and upper thrust wash-

ers together with the cylinder block.

EG–104

–ENGINE TROUBLESHOOTING ENGINE MECHANICAL

Loading...

Loading...