2. INSPECT PISTON

A. Inspect piston oil clearance

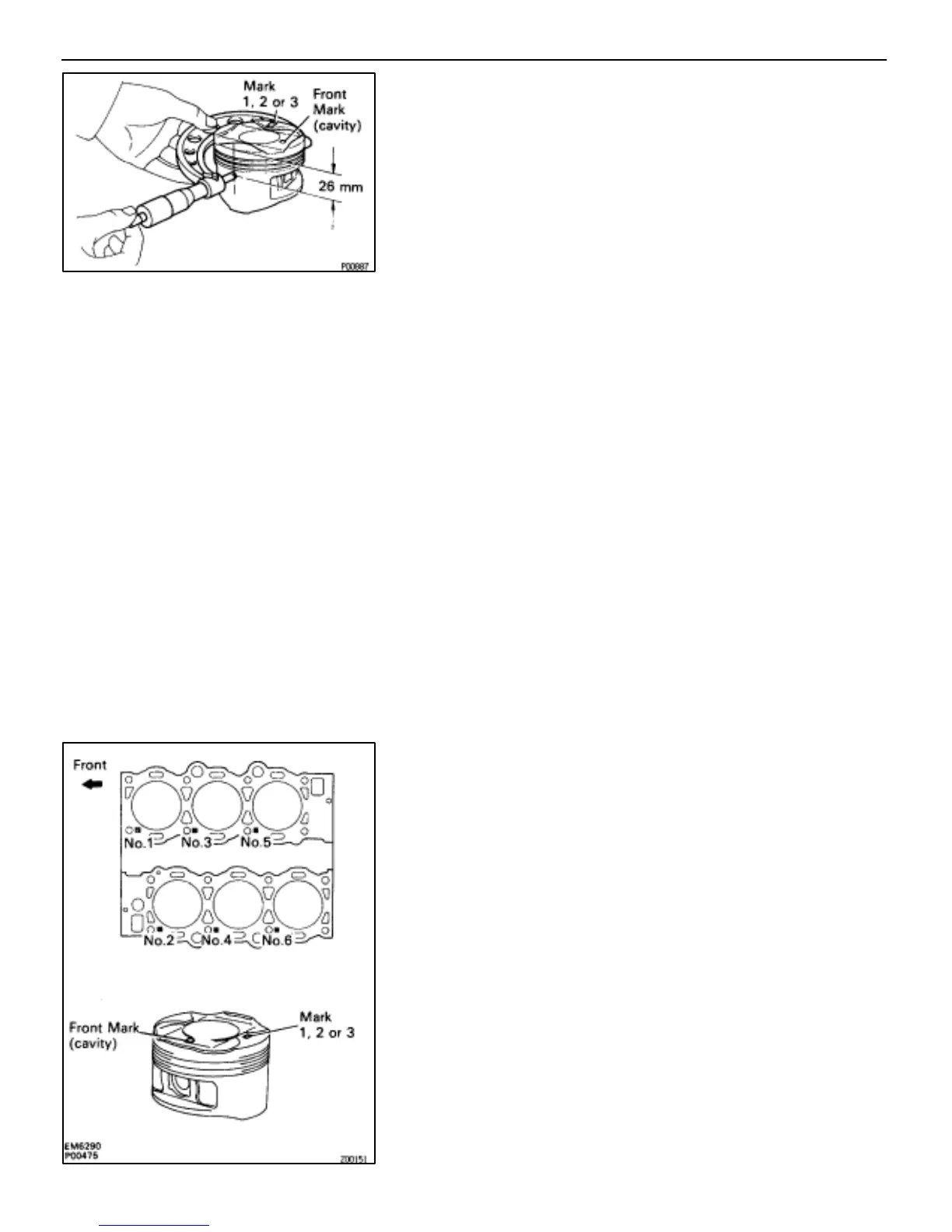

HINT: There are three sizes of the standard diameter, marked

”1”, ”2” and ”3” accordingly. The mark is stamped on the top

of the piston.

(a) Using a micrometer, measure the piston diameter at right

angles to the piston pin center line, 26 mm (1.02 in.) from the

piston head.

Piston diameter:

STD

Mark ”1”

87.360–87.370 mm (3.4394–3.4398 in.)

Mark ”2”

87.370–87.380 mm (3.4398–3.4402 in.)

Mark ”3”

87.380–87.390 mm (3.4402–3.4405 in.)

O/S 0.50

87.410–87.440 mm (3.4413–3.4425 in.)

(b) Measure the cylinder bore diameter in the thrust directions.

(See step 5 on page EG–108)

(c) Subtract the piston diameter measurement from the cylinder

bore diameter measurement.

Standard oil clearance:

0.13–0.15 mm (0.0051–0.0059 in.)

Maximum oil clearance:

0.17 mm (0.0067 in.)

If the oil clearance is greater than maximum, replace all the

six pistons. If necessary, rebore all the six cylinders or replace

the cylinder block.

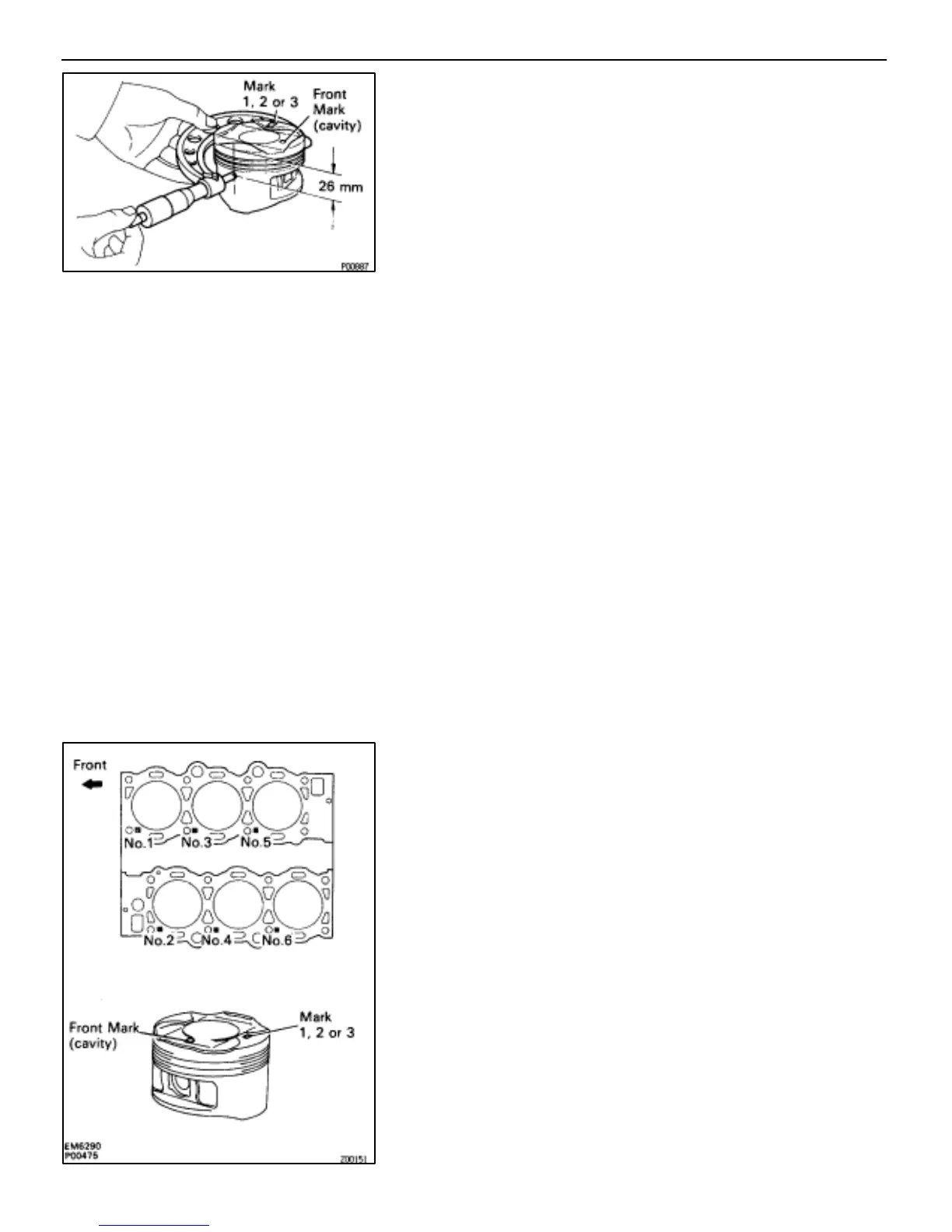

HINT (Use new cylinder block): Use a piston with the same

number mark as the standard bore diameter marked on the

cylinder block.

–ENGINE TROUBLESHOOTING ENGINE MECHANICAL

EG–111

Loading...

Loading...