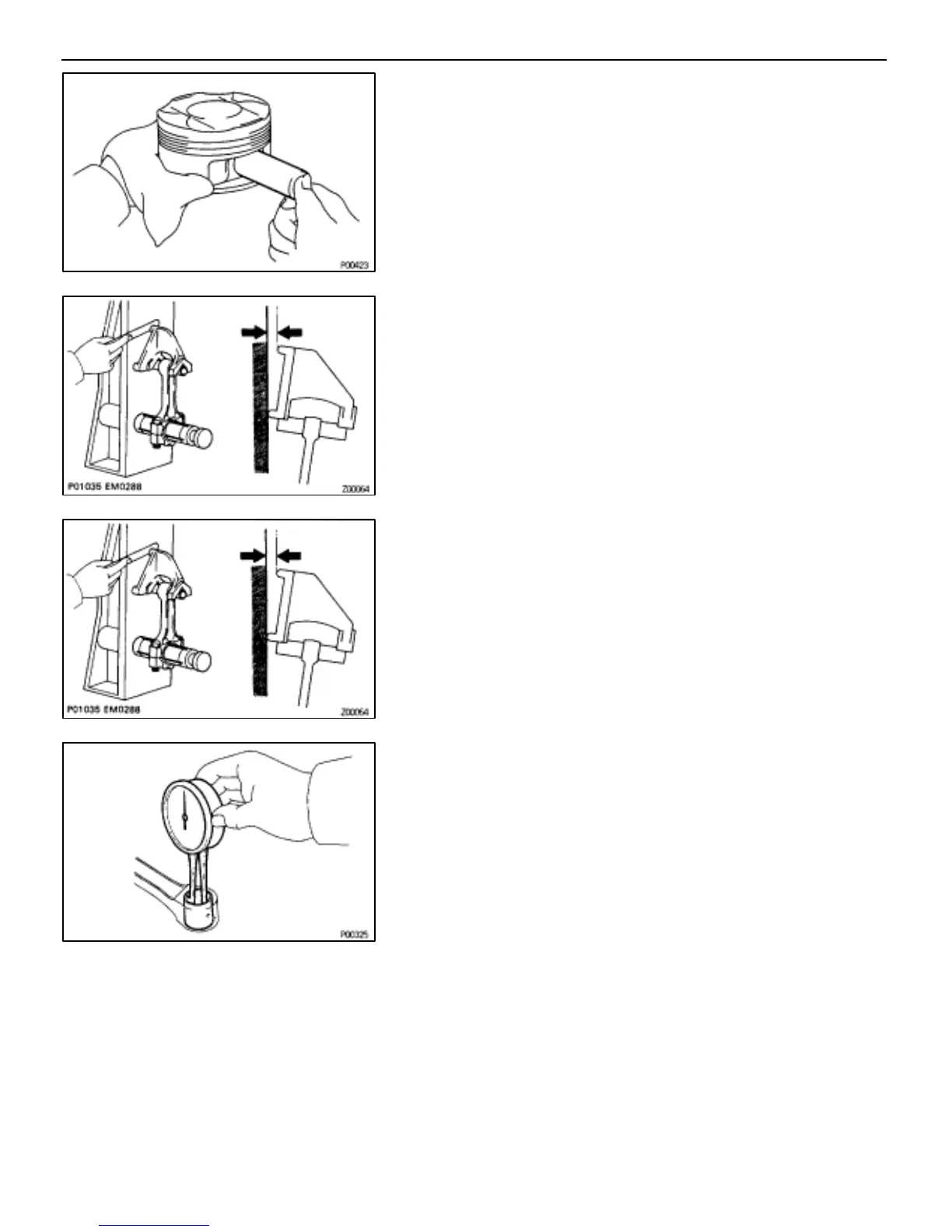

D. Inspect piston pin fit

At 60°C (140°F), you should be able to push the piston pin

into the piston pin hole with your thumb.

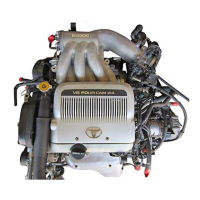

3. INSPECT CONNECTING ROD

A. Inspect connecting rod alignment

Using a rod aligner and thickness gauge, check the connect-

ing rod alignment.

•Check for bend.

Maximum bend:

0.05 mm (0.0020 in.) per 100 mm (3.94 in.)

If bend is greater than maximum, replace the connecting rod

assembly.

•Check for twist.

Maximum twist:

0.15 mm (0.0059 in.) per 100 mm (3.94 in.)

If twist is greater than maximum, replace the connecting rod

assembly.

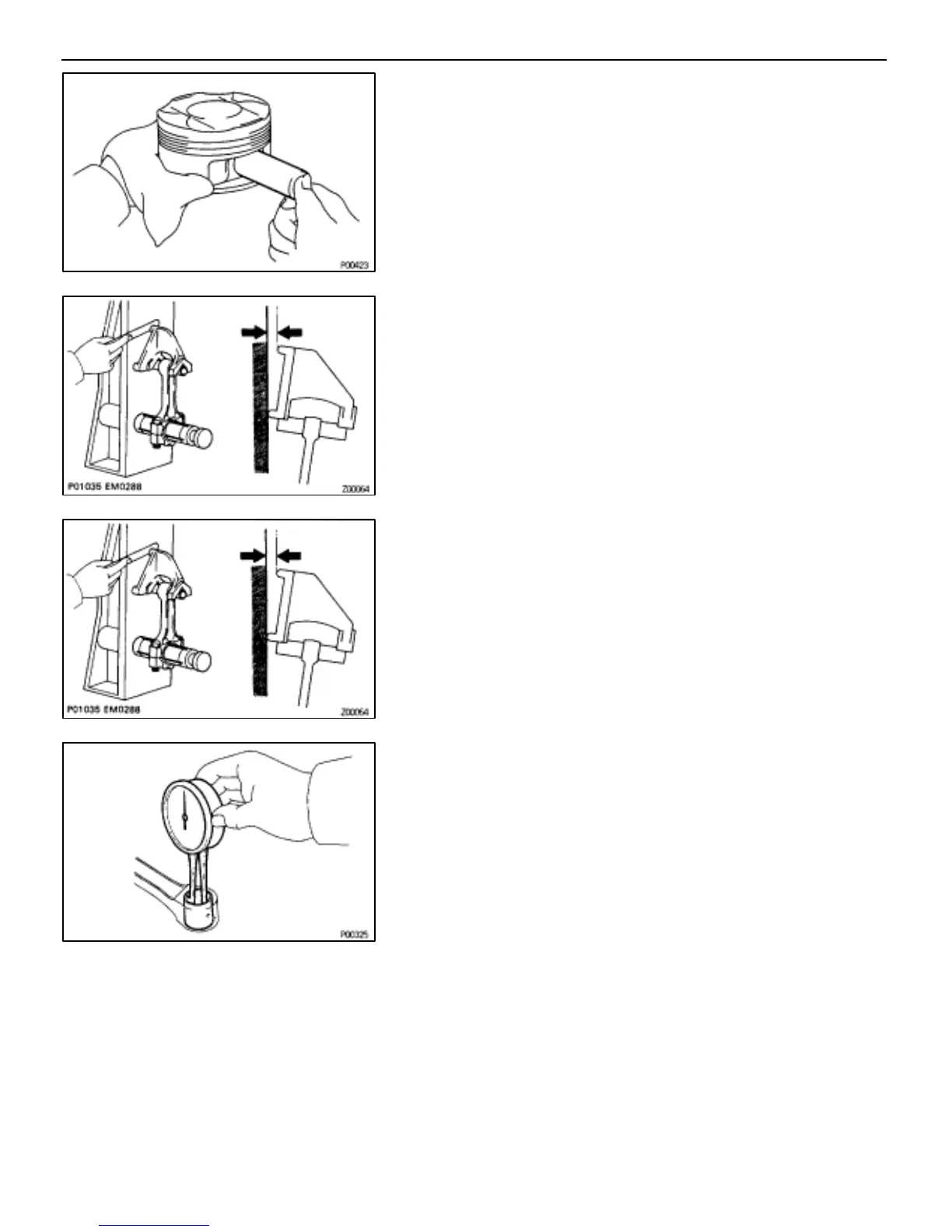

B. Inspect piston pin oil clearance

(a) Using a caliper gauge, measure the inside diameter of the

connecting rod bushing.

Bushing inside diameter:

22.005–22.014 mm (0.8663–0.8667 in.)

(b) Using a micrometer, measure the piston pin diameter.

Piston pin diameter:

21.997–22.006 mm (0.8660–0.8664 in.)

(c) Subtract the piston pin diameter measurement from the

bushing inside diameter measurement.

Standard oil clearance:

0.005–0.011 mm (0.0002–0.0004 in.)

Maximum oil clearance:

0.05 mm (0.0020 in.)

If the oil clearance is greater than maximum, replace the

bushing. If necessary, replace the piston and piston pin as a

set.

–ENGINE TROUBLESHOOTING ENGINE MECHANICAL

EG–113

Loading...

Loading...