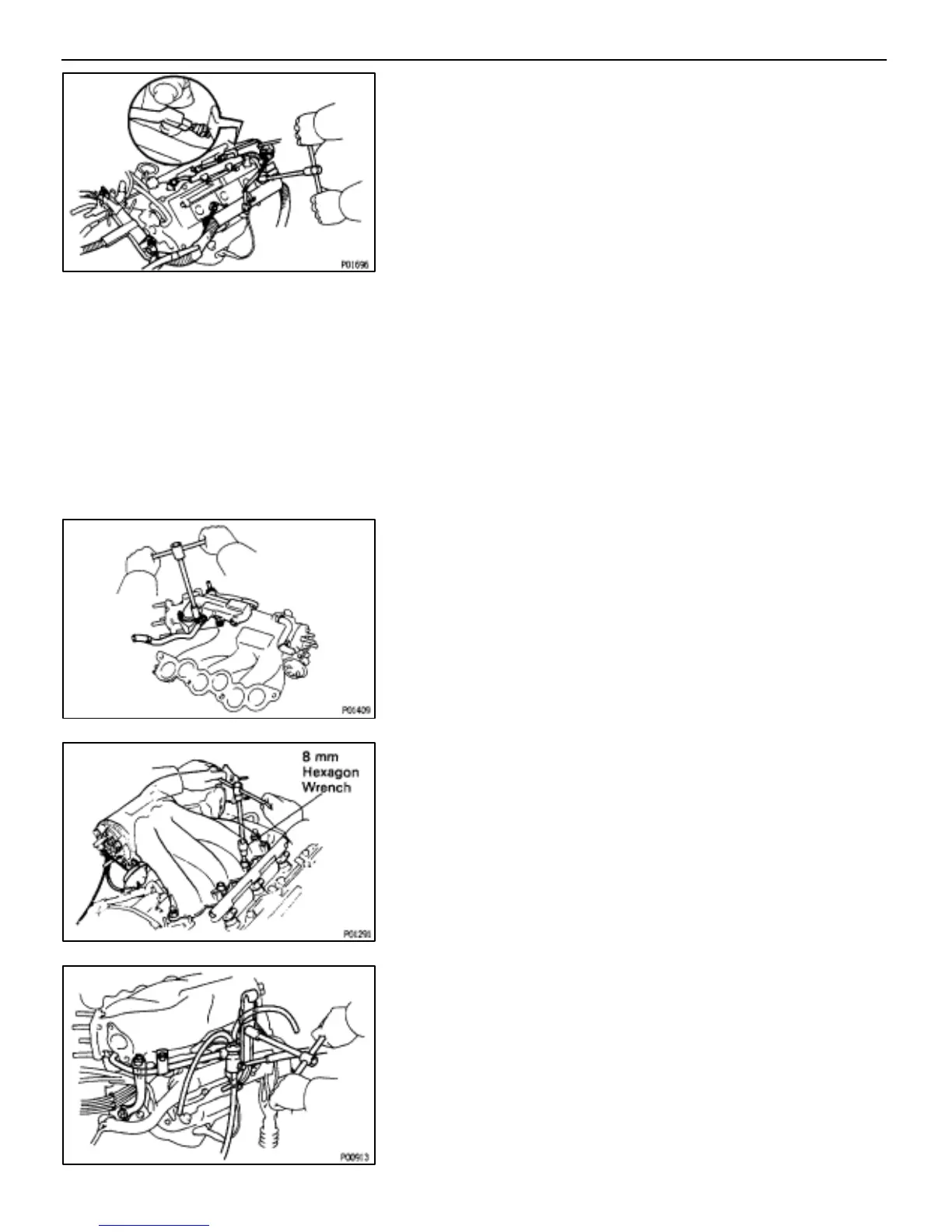

20. CONNECT RH ENGINE WIRE HARNESS

(a) Connect the two clamps, and install the engine wire harness

with the four bolts.

(b) Connect the following connectors:

(1) Three injector connectors

(2) Engine coolant temp. sender gauge connector

(3) Oxygen sensor connector

(4) PS pump connector

(5) Oil pressure switch connector

(6) Engine oil level sensor connector

(7) A/C compressor connector

(8) Engine coolant temp. sensor connector (for hydraulic

cooling fan)

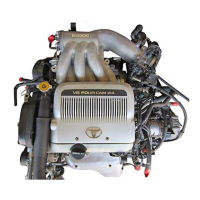

21. INSTALL NO.1 EGR COOLER

Install a new gasket and the No.1 EGR cooler with the bolt

and two nuts.

Torque: 18 N⋅m (185 kgf⋅cm, 13 ft⋅lbf)

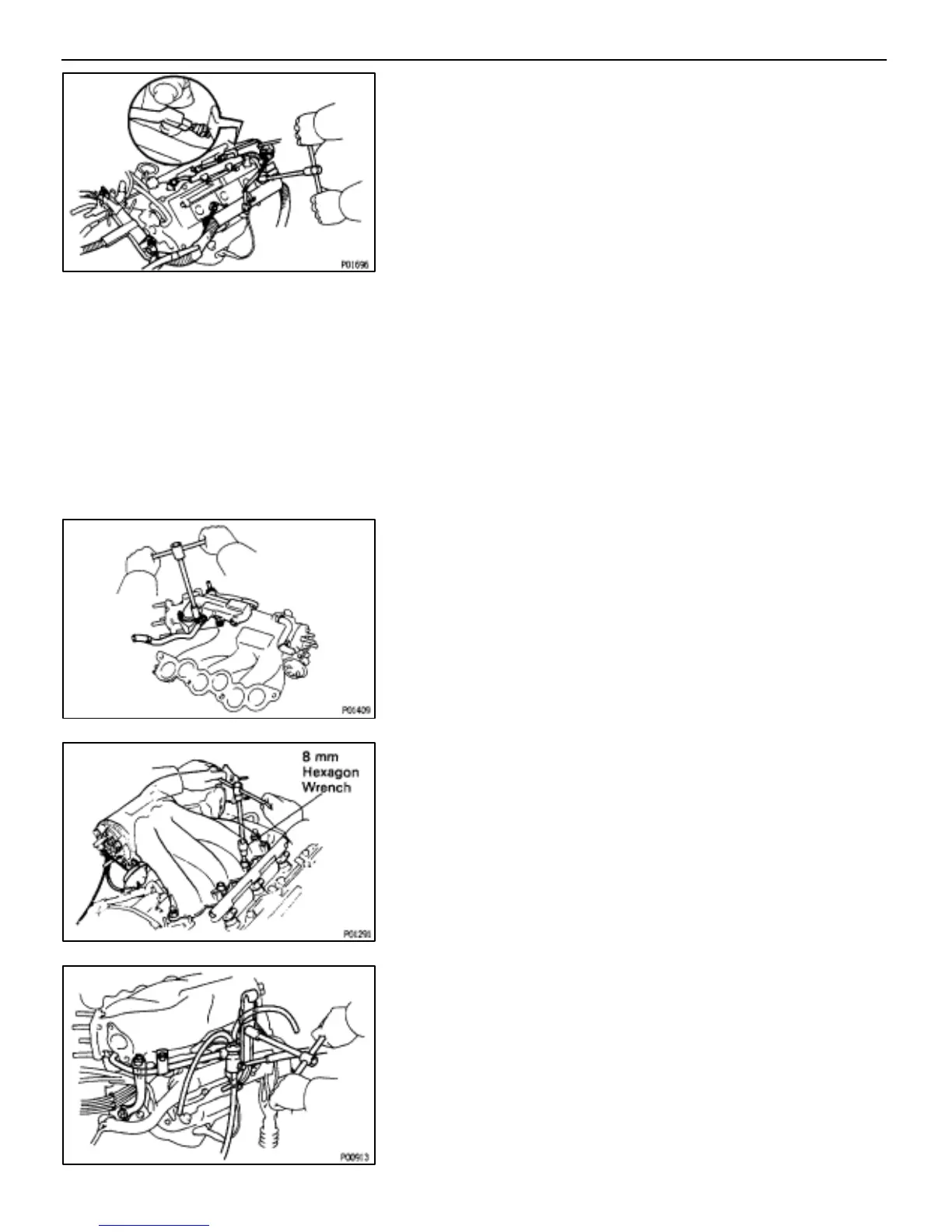

22. INSTALL AIR INTAKE CHAMBER

(a) Using 8 mm hexagon wrench, install a new gasket and the air

intake chamber with the two bolts and nuts.

Uniformly tighten the bolts and nuts in several passes.

Torque: 43 N⋅m (440 kgf⋅cm, 32 ft⋅lbf)

(b) Connect the two ground straps with the nut.

Torque: 13 N⋅m (130 kgf⋅cm, 9 ft⋅lbf)

(c) Connect the hydraulic pressure pipe with the bolt.

Torque: 20 N⋅m (200 kgf⋅cm, 14 ft⋅lbf)

(d) Install the air intake chamber stay.

Torque: 39 N⋅m (400 kgf⋅cm, 29 ft⋅lbf)

(e) Install the No.1 engine hanger.

Torque: 39 N⋅m (400 kgf⋅cm, 29 ft⋅lbf)

(f) Connect the PS ACV with the nut.

–ENGINE TROUBLESHOOTING ENGINE MECHANICAL

EG–83

Loading...

Loading...