(d) Repeat steps (a) through (c) for each cylinder.

NOTICE: This measurement must be done in as short a

time as possible.

Compression pressure:

1,226 kPa (12.5 kgf/cm

2

, 178 psi) or more

Minimum pressure:

981 kPa (10.0 kgf/cm

2

, 142 psi)

Difference between each cylinder:

98 kPa (1.0 kgf/cm

2

, 14 psi) or less

(e) If the cylinder compression in one or more cylinders is low,

pour a small amount of engine oil into the cylinder through the

spark plug hole and repeat steps (a) through (c) for cylinders

with low compression.

•If adding oil helps the compression chances are that the

piston rings and/or cylinder bore are worn or damaged.

•If pressure stays low, a valve may be sticking or seating is

improper, or there may be leakage past the gasket.

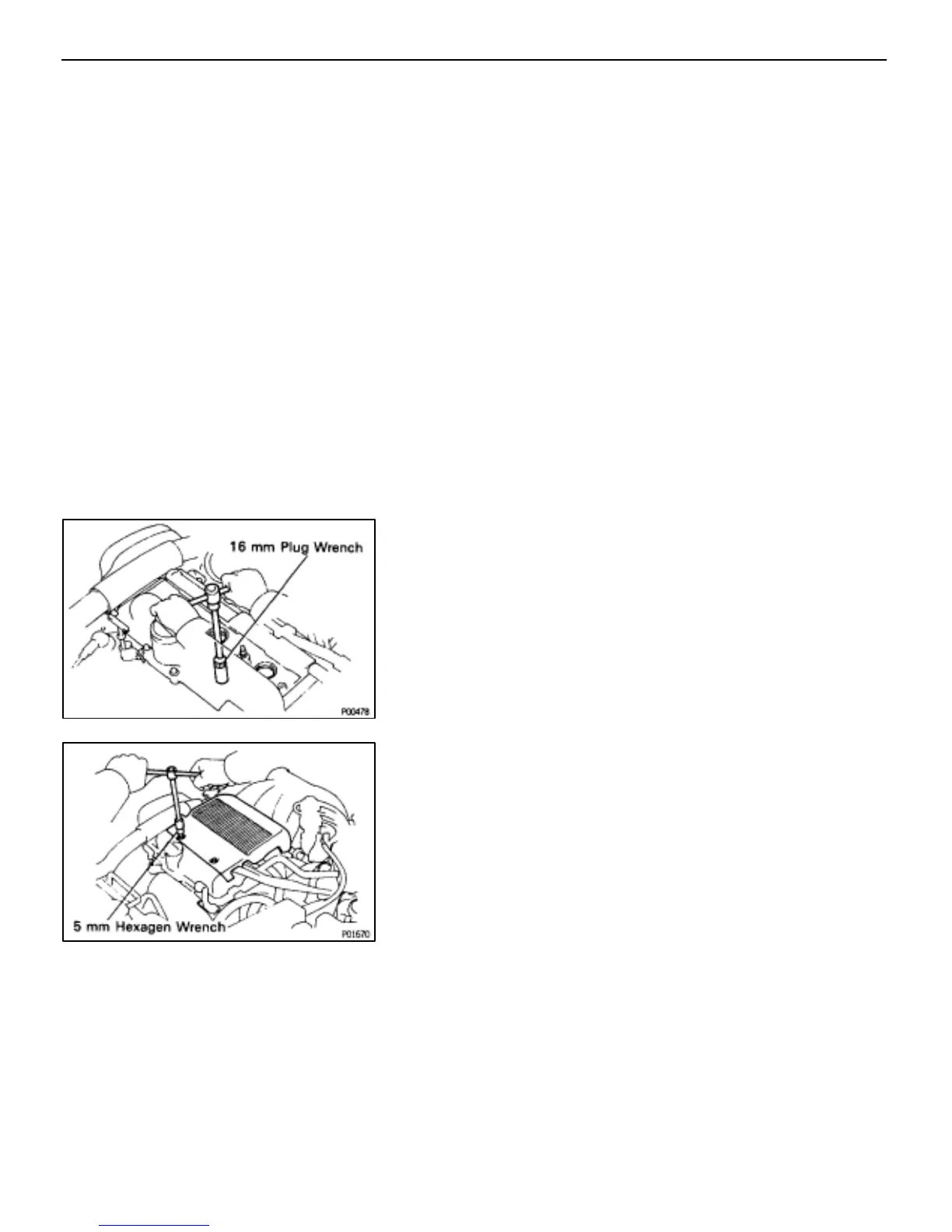

7. REINSTALL SPARK PLUGS

Using a 16 mm plug wrench, install the spark plug.

Torque: 18 N⋅m (180 kgf⋅cm, 13 ft⋅lbf)

8. RECONNECT HIGH–TENSION CORDS TO SPARK

PLUGS

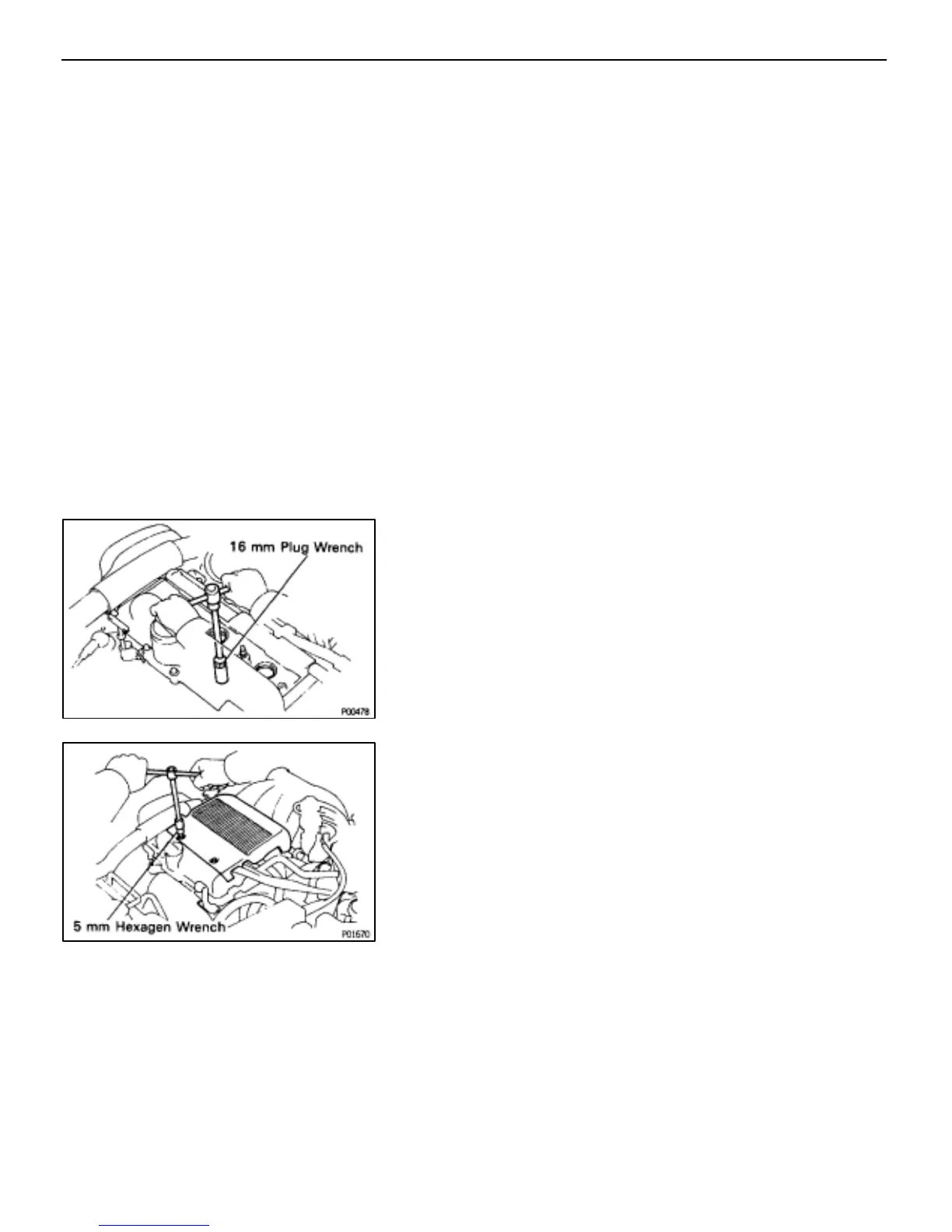

9. REINSTALL V–BANK COVER

Using a 5 mm hexagon wrench, install the V–bank cover with

the two nuts.

10. RECONNECT DISTRIBUTOR CONNECTOR

EG–28

–ENGINE TROUBLESHOOTING ENGINE MECHANICAL

Loading...

Loading...