FUEL VAPOR LINES, FUEL TANK AND

TANK CAP INSPECTION

EG08K–01

1. VISUALLY INSPECT LINES AND CONNECTIONS

Look for loose connections, sharp bends or damage.

2. VISUALLY INSPECT FUEL TANK

Look for deformation, cracks or fuel leakage.

3. VISUALLY INSPECT FUEL TANK CAP

Check if the cap and / or gasket are deformed or damaged.

If necessary, repair or replace the cap.

CHARCOAL CANISTER INSPECTION

EG08L–01

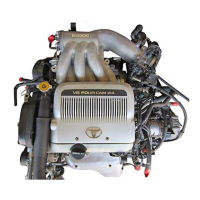

1. REMOVE CHARCOAL CANISTER

2. VISUALLY INSPECT CHARCOAL CANISTER

Look for cracks or damage.

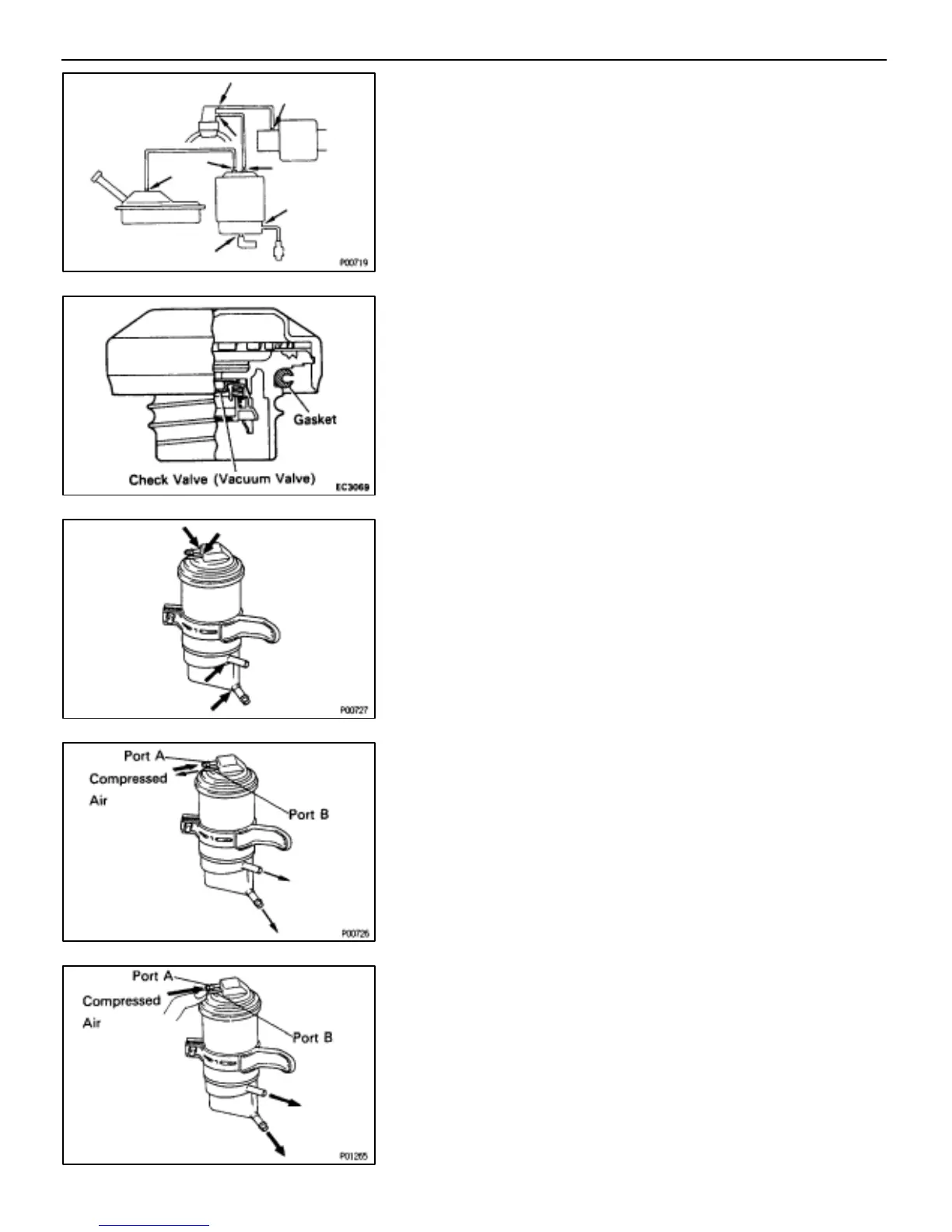

3. CHECK FOR CLOGGED FILTER AND STUCK CHECK

VALVE

(a) Using low pressure compressed air, blow into port A and

check that air flows without resistance from the other ports.

(b) Blow into port B and check that air does not flow from the

other ports.

If a problem is found, replace the charcoal canister.

4. CLEAN FILTER IN CANISTER

Clean the filter by blowing 294 kPa (3 kgf/cm

2

, 43 psi) of com-

pressed air into port A while holding port B closed.

NOTICE:

• Do not attempt to wash the canister.

• No activated carbon should come out.

5. REINSTALL CHARCOAL CANISTER

–ENGINE TROUBLESHOOTING EMISSION CONTROL SYSTEMS

EG–149

Loading...

Loading...