OIL PUMP INSTALLATION

EG09E–02

(See page EG–294)

1. INSTALL OIL PUMP

(a) Remove any old packing (FIPG) material and be careful not

to drop and oil on the contact surfaces of the oil pump and

cylinder block.

•Using a razor blade and gasket scraper, remove all the old

packing (FIPG) material from the gasket surfaces and

sealing grooves.

•Thoroughly clean all components to remove all the loose

material.

•Using a non–residue solvent, clean both sealing surfaces.

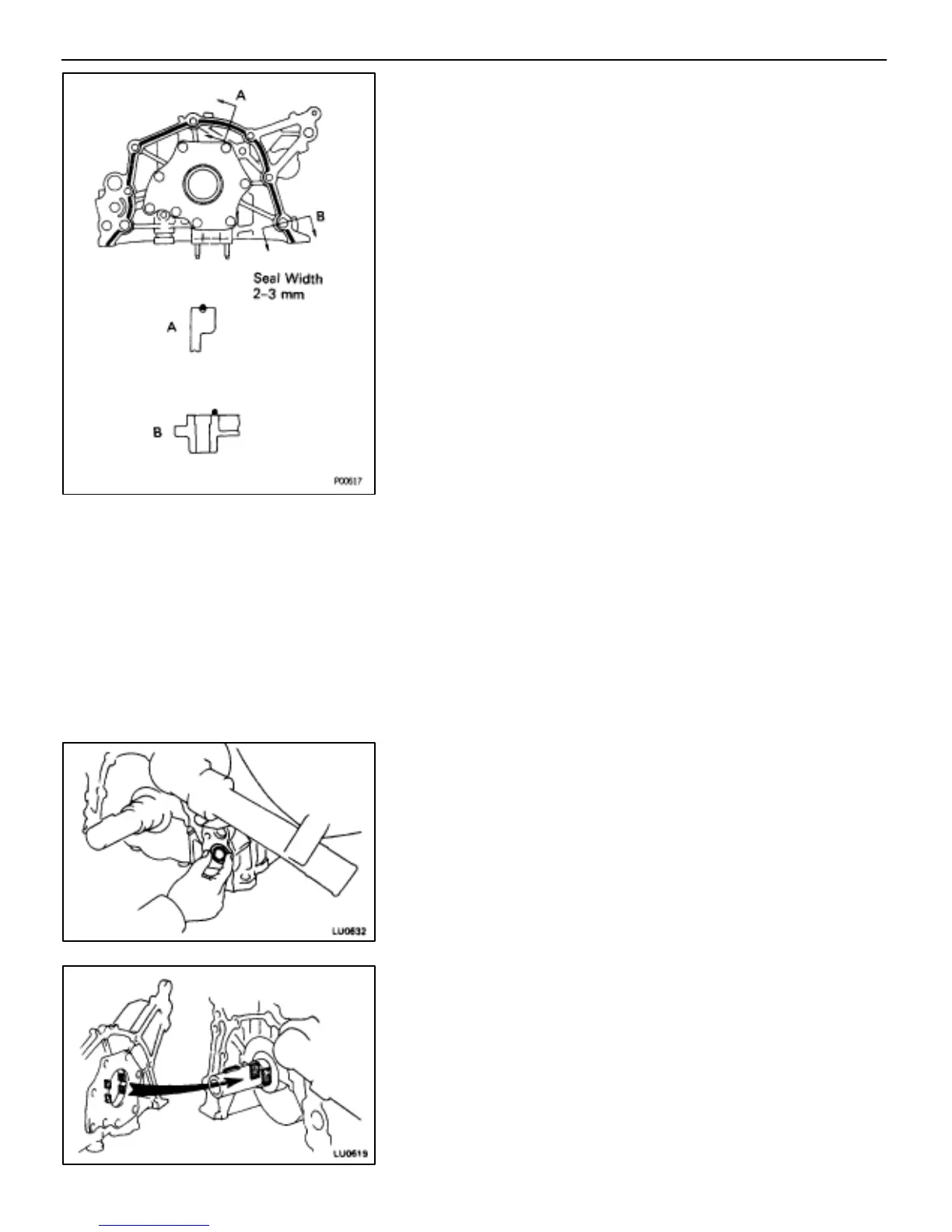

(b) Apply seal packing to the oil pump as shown in the illustration.

Seal packing:

Part No. 08826–00080 or equivalent

•Install a nozzle that has been cut to a 2–3 mm (0.08–0.12

in.) opening.

HINT: Avoid applying an excessive amount to the surface.

•Parts must be assembled within 5 minutes of application.

Otherwise the material must be removed and reapplied.

•Immediately remove nozzle from the tube and reinstall cap.

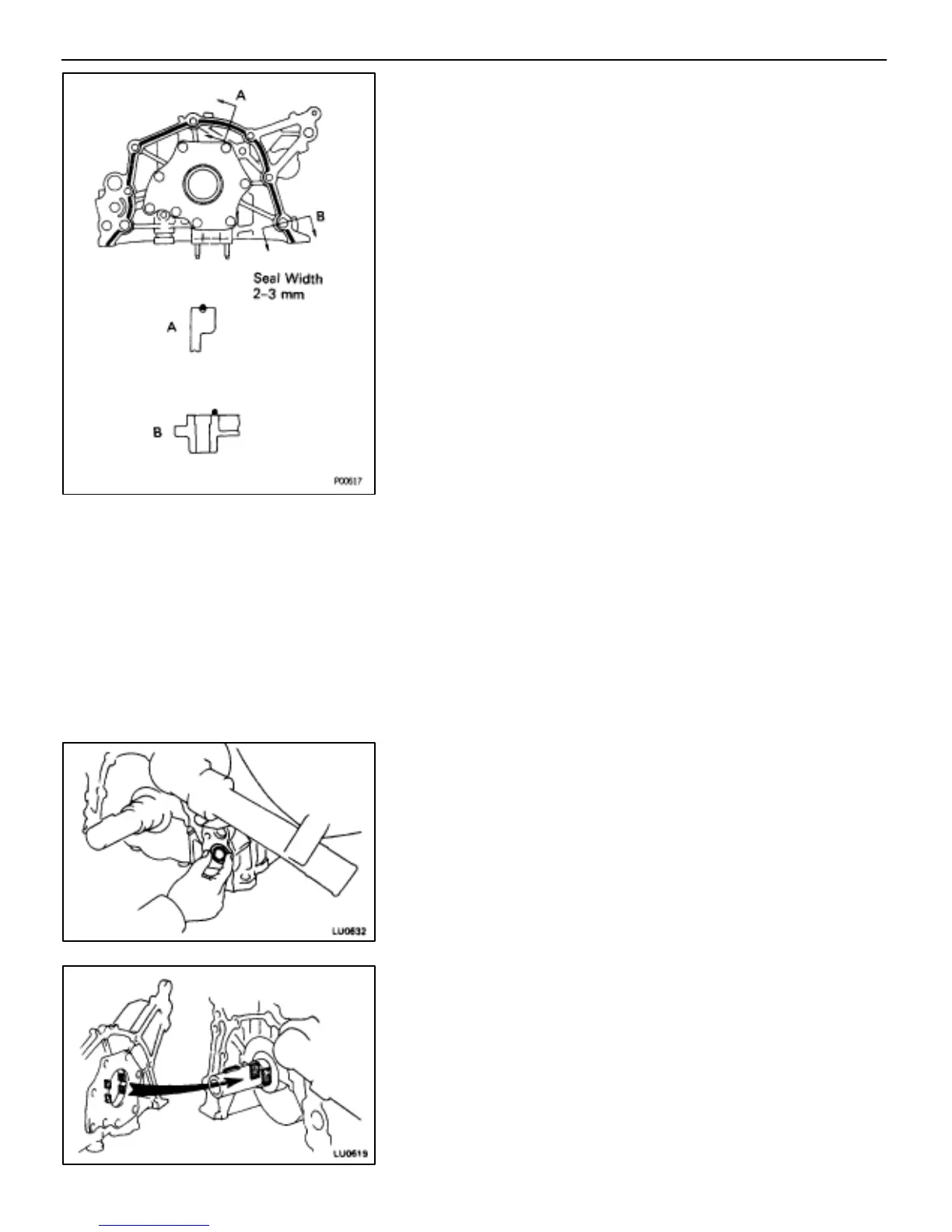

(c) Place a new O–ring in position on the cylinder block.

(d) Engage the spline teeth of the oil pump drive gear with the

large teeth of the crankshaft, and slide.

EG–302

–ENGINE TROUBLESHOOTING LUBRICATION SYSTEM

Loading...

Loading...