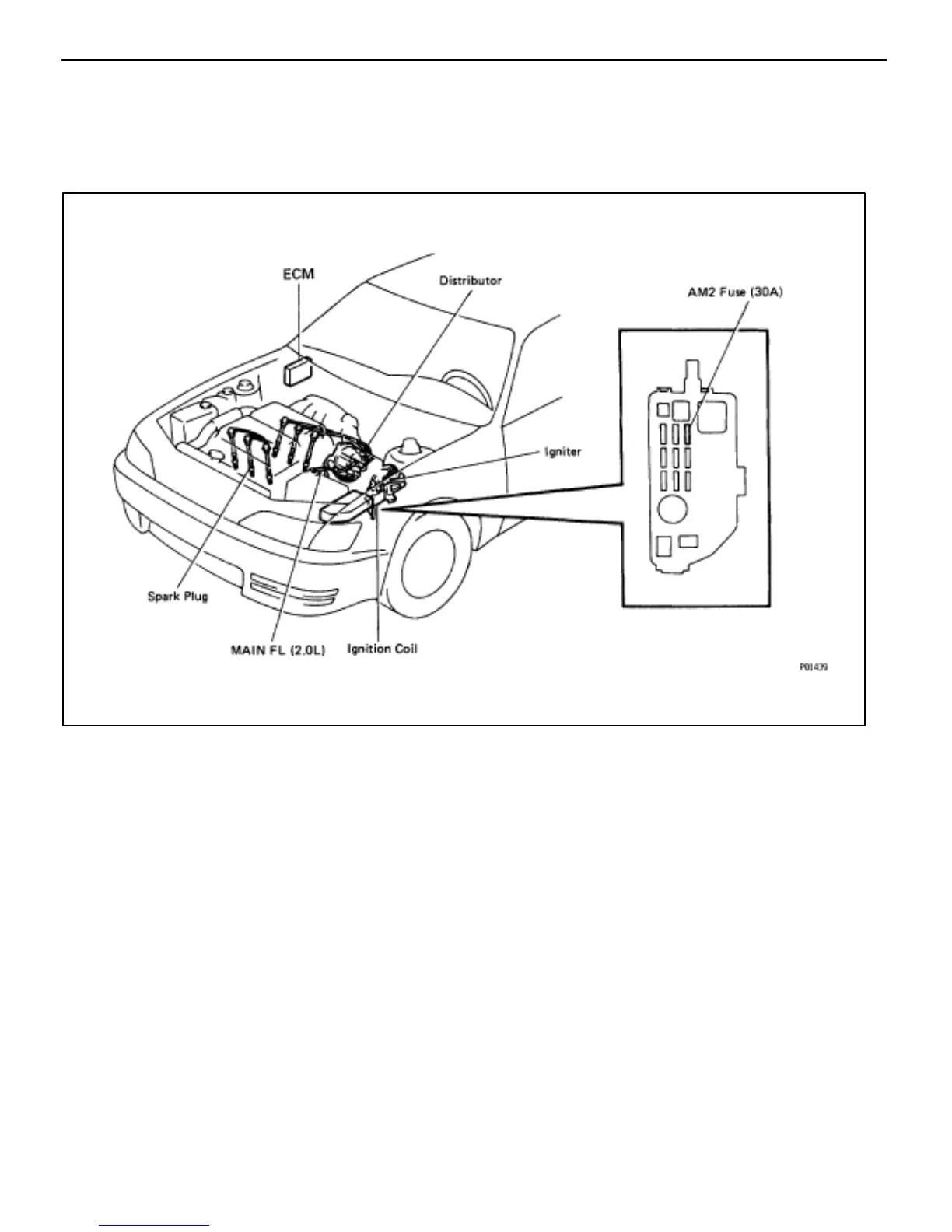

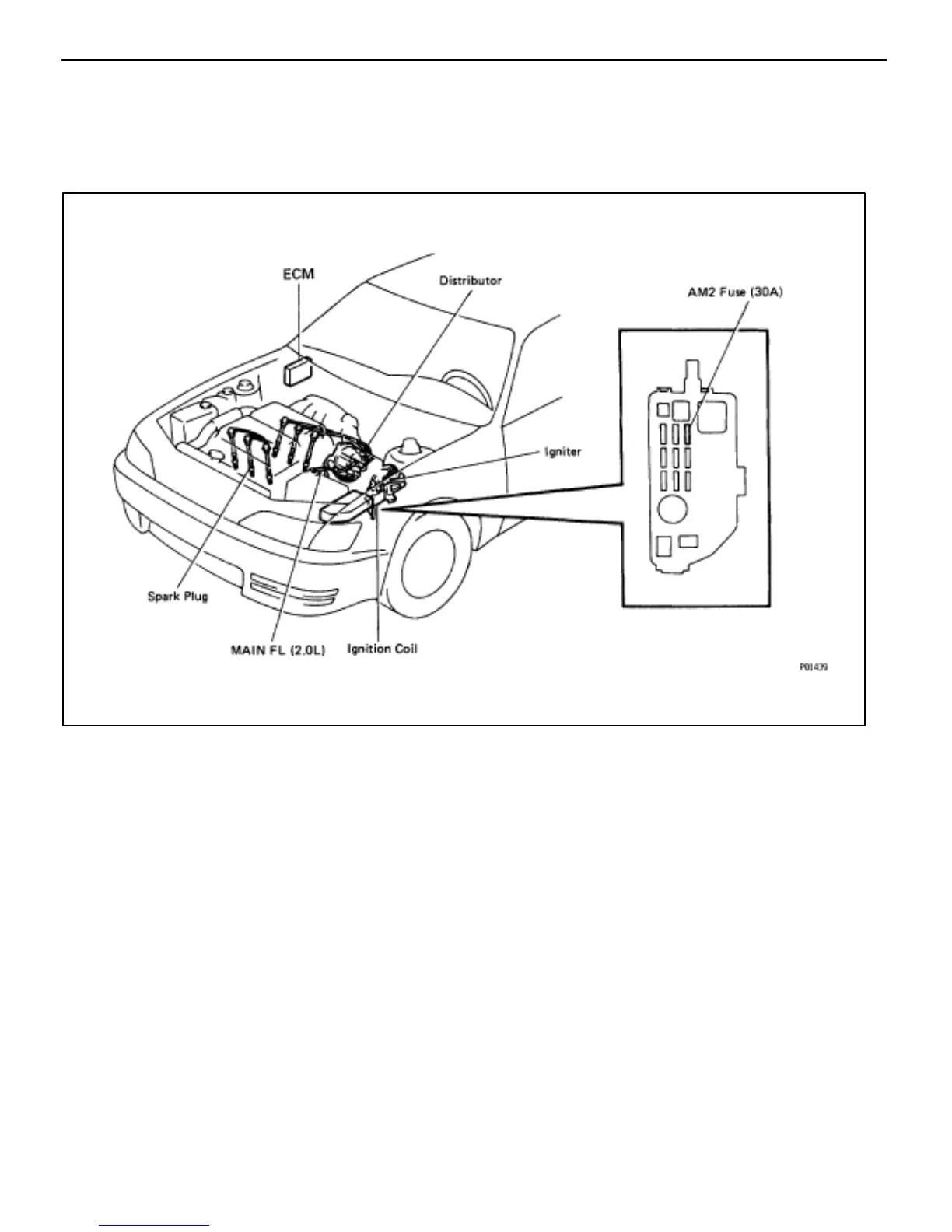

DESCRIPTION

IG018–02

The ECM is programmed with data for optimum ignition timing under any and all operating conditions. Us-

ing data provided by sensors which monitor various engine functions (rpm, intake air volume, eng, temper-

ature, etc.), the microcomputer (ECM) triggers the spark at precisely the right instant.

The ECM monitors the engine condition by signals from each sensor, calculates the ignition timing and

sends an ignition signal to the igniter. High voltage from the ignition is distributed to each spark plug in the

appropriate order to generate a spark between the electrodes, which ignites the air–fuel mixture.

IGNITER

The igniter temporarily interrupts the primary current with the ignition signal (IGT signal) from the ECM and

generates sparks at the spark plug. Also, as a fail–safe measure, when ignition occurs an ignition confirma-

tion signal (IGF signal) is sent to the ECM.

IGNITION COIL

The ignition coil uses a closed core coil with the primary coil wrapped around the core and the secondary

coil wrapped around the primary coil. This allows the generation of a high voltage sufficient to cause a spark

to jump across the spark plug gap.

DISTRIBUTOR

This correctly distributes high voltage to the spark plug of each cylinder in the specified ignition order.

PICKUP COILS

The NE coil detects the crankshaft position, and the G1 and G2 coils detect the camshaft position.

IG–2

–IGNITION SYSTEM DESCRIPTION

Loading...

Loading...