FIELD OPERATION

4-36

ROTARY SEPARATOR

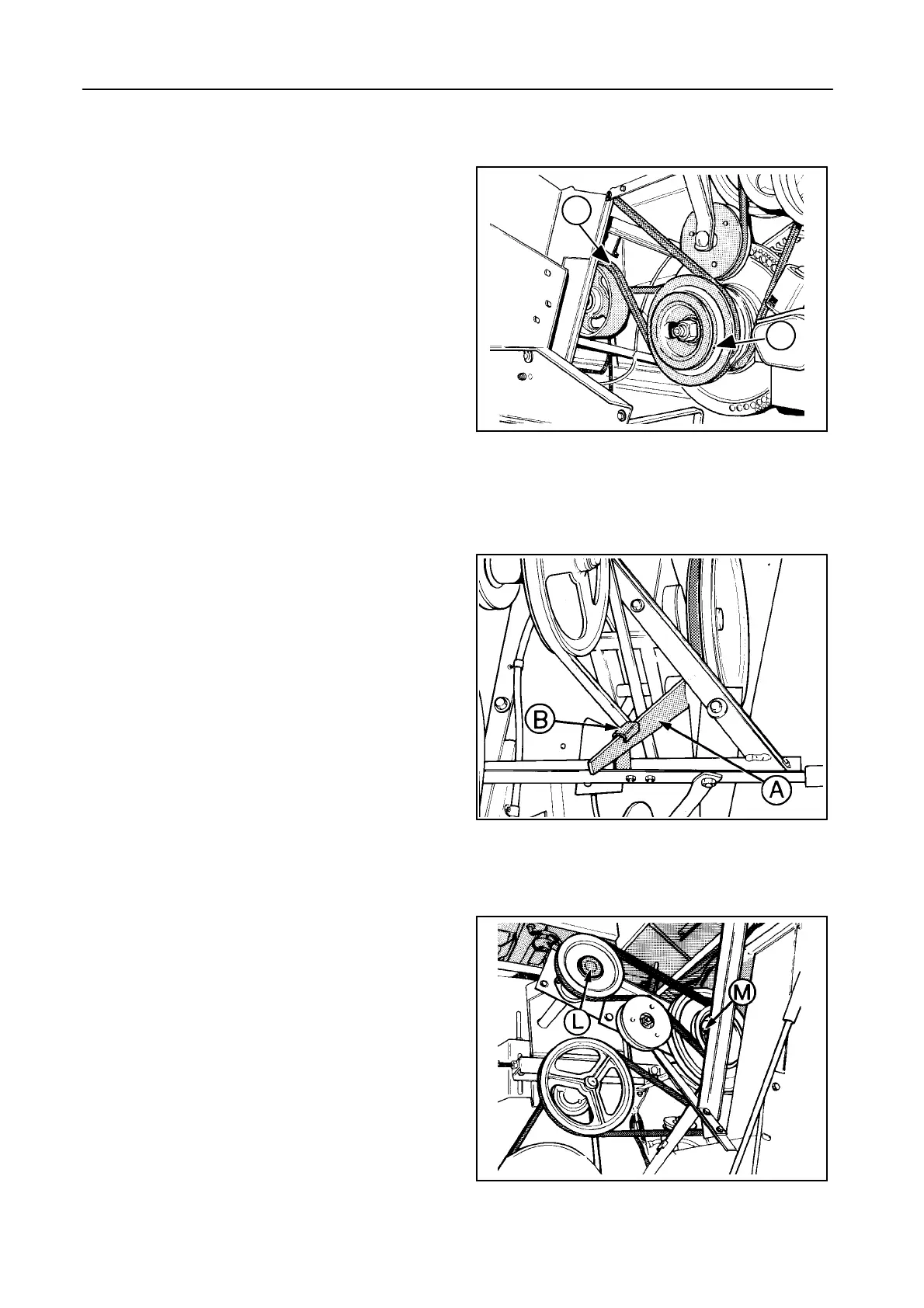

ROTARY SEPARATOR SPEED -- Figures 53 and 54

The rotary separator is driven by pulley V which has a

double groove for an alternative speed:

S 760 rpm is the factory-set speed which is suit-

able for most crops such as barley, oats, rye,

wheat, rice, grass seed, etc.

S 400 rpm is for harvesting maize, beans, peas,

soya, sunflower, oil seed rape, etc.

To change the speed, proceed as follows:

1. Move lever A out of hook B and upwards.

This will move the idler C downwards and loosen

the belt tension.

2. Install the belt in the other grooves of both pulleys.

3. Move lever A downwards and secure the lever in

hook B as shown.

4. Check the belt tension and adjust, if necessary

(refer to Section 5 - ADJUSTMENTS AND MAIN-

TENANCE, paragraph headed ‘‘Belts and

chains’’).

The rotary separator is accessible through the cover

which is situated underneath the grain tank.

CONCAVE POSITION

Refer to paragraph headed ‘ ‘ Multi-thresh system’’.

40843

53

40845

54

C

V

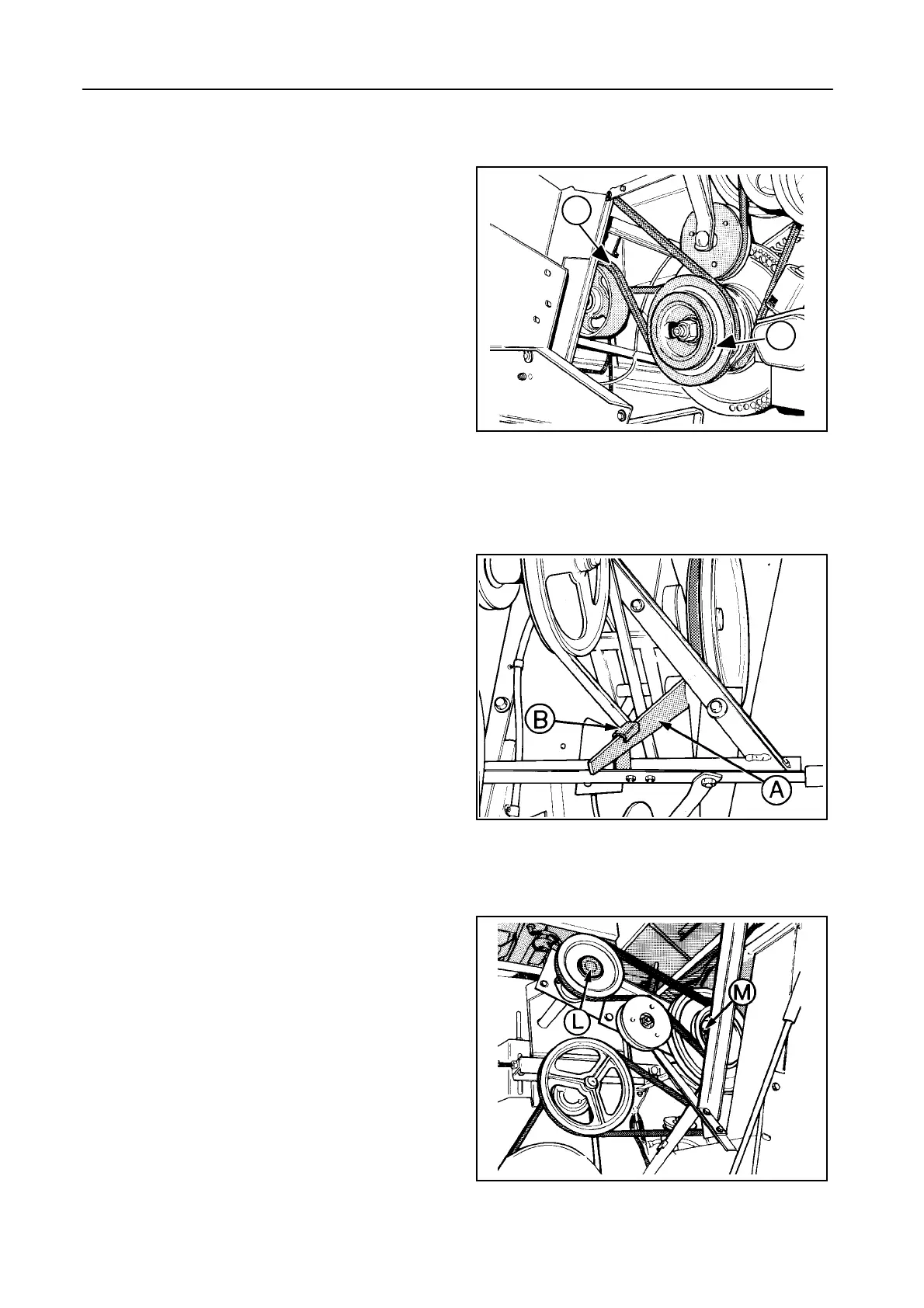

STRAW FLOW BEATER [i f installed] -- Figure 55

The function of the Straw Flow beater L is to improve

the combine throughput capacity in specific condi-

tions (heavy green, damp straw).

On combines equipped with a Straw Flow beater L

and operating in severe crop conditions (very dry or

brittle), the rotary separator M, and so the Straw Flow

beater L, can be set on low rpm speed (400 rpm) if the

straw breaks up too easily.

30217

55

Loading...

Loading...