OPERATION

2-2

2

51512

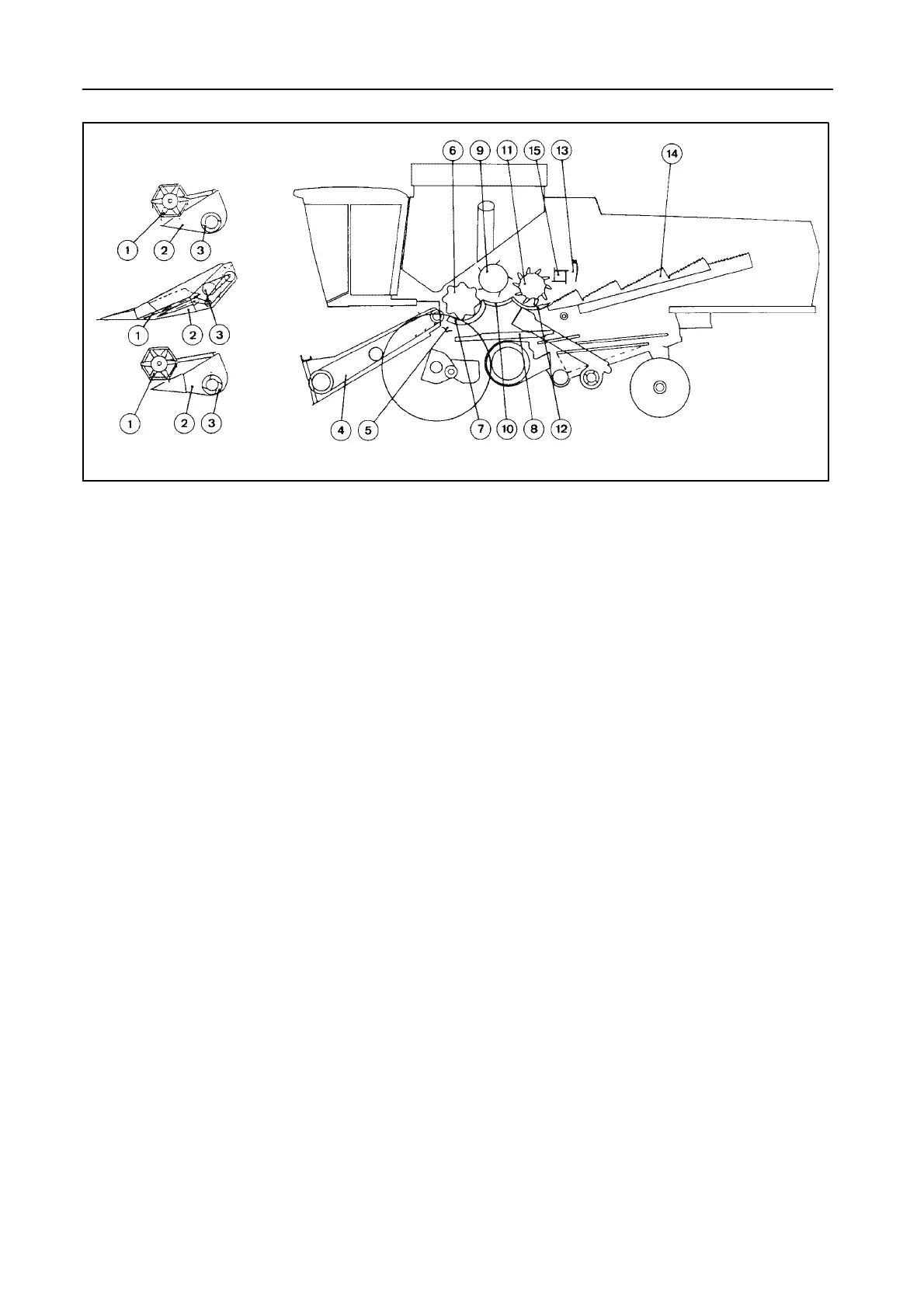

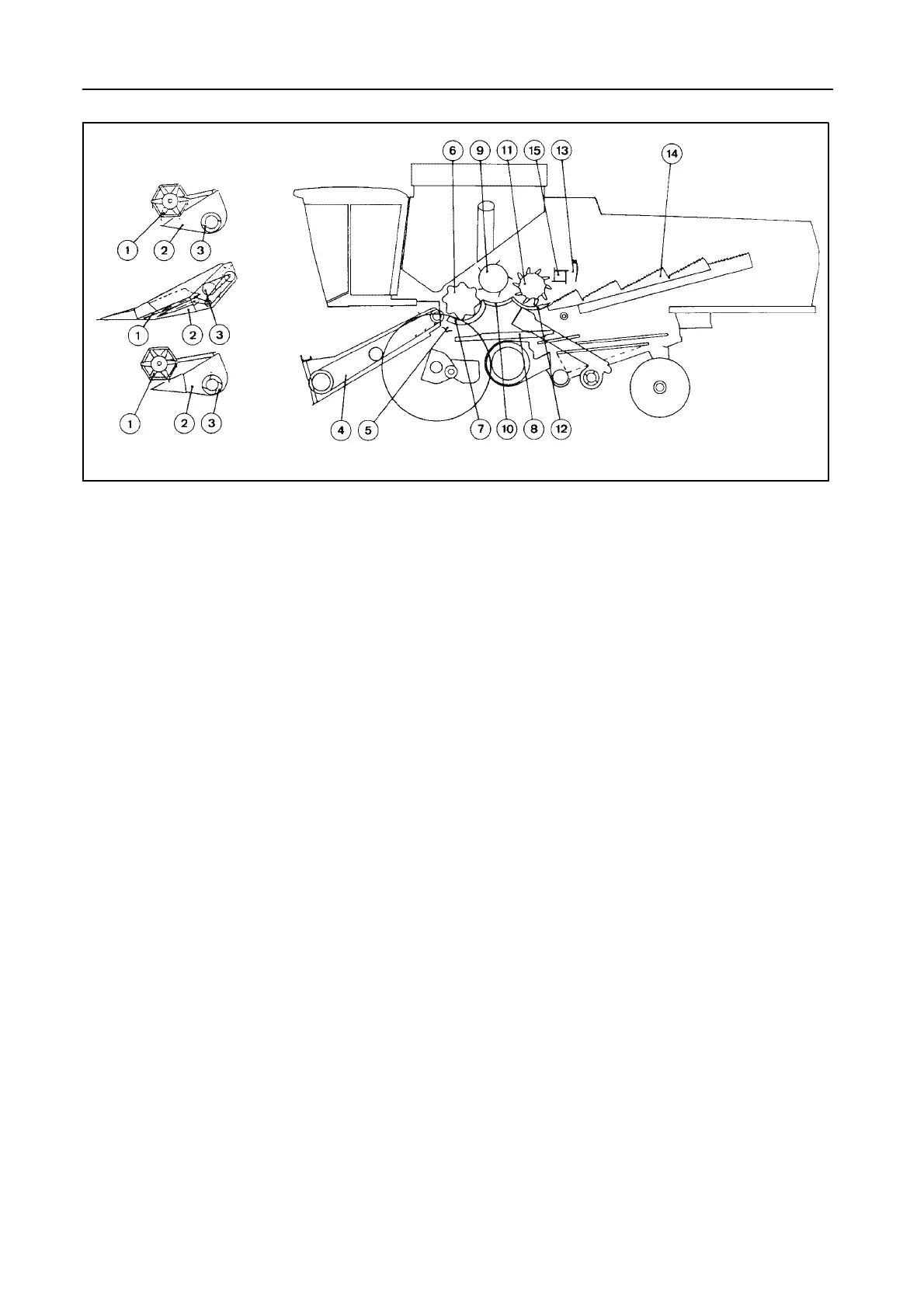

1. FEEDING -- Figure 2

The reel 1 (on the grain or flex header) or the gather-

ing chain (on the maize header) feeds the crop/cobs

into the header 2 towards the auger 3. The auger 3

feeds the crop into the front of the straw elevator 4.

Models with lateral flotation only:

The straw elevator head pivots on the elevator frame

which enables the header to follow deviations in slope

of up to 3° on either side, relative to the base unit posi-

tion.

The crop is then carried up the straw elevator where it

is fed over the stone trap 5 into the drum and concave

area. At this point the feeding is complete and the

threshing starts.

The stone trap 5 is designed to trap stones and other

foreign objects which may cause damage to internal

parts of the combine.

2. THRESHING -- Figure 2

As the drum 6 rotates, it rubs the crop against the bars

of concave 7. This rubbing action threshes approxi-

mately 90% of the grain from the straw.

S Clean grain falls onto the grain pan 8.

S Straw (and a little grain) are guided to the beater 9.

S De-awning plates can be swung up underneath

the concave to increase the rubbing action when

threshing winter barley or difficult-to-thresh crops.

S Rasp bars [accessory] can be installed on the

front part of the concave to improve the threshing

efficiency (especially important in wheat) and to

avoid white caps.

Loading...

Loading...