ADJUSTMENTS AND MAINTENANCE

5-18

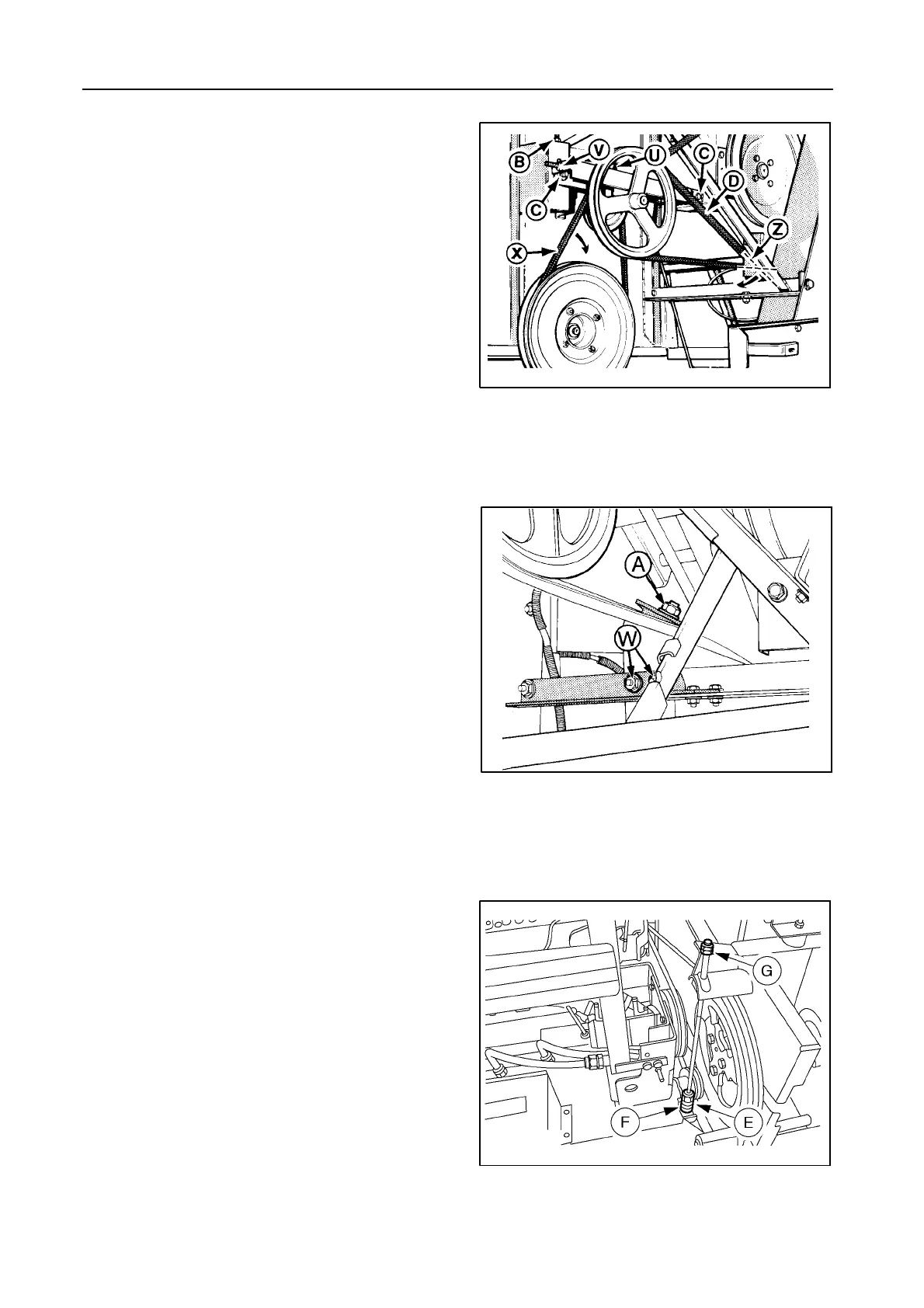

21 STRAW WALKER INTERMEDIATE SHAFT

DRIVE BELT -- Figures 33 and 34

The belt tension is correct when belt D can be de-

flected 14 mm at Z when applying a force of 17 N.

Adjust with rod V after loosening the three bolts

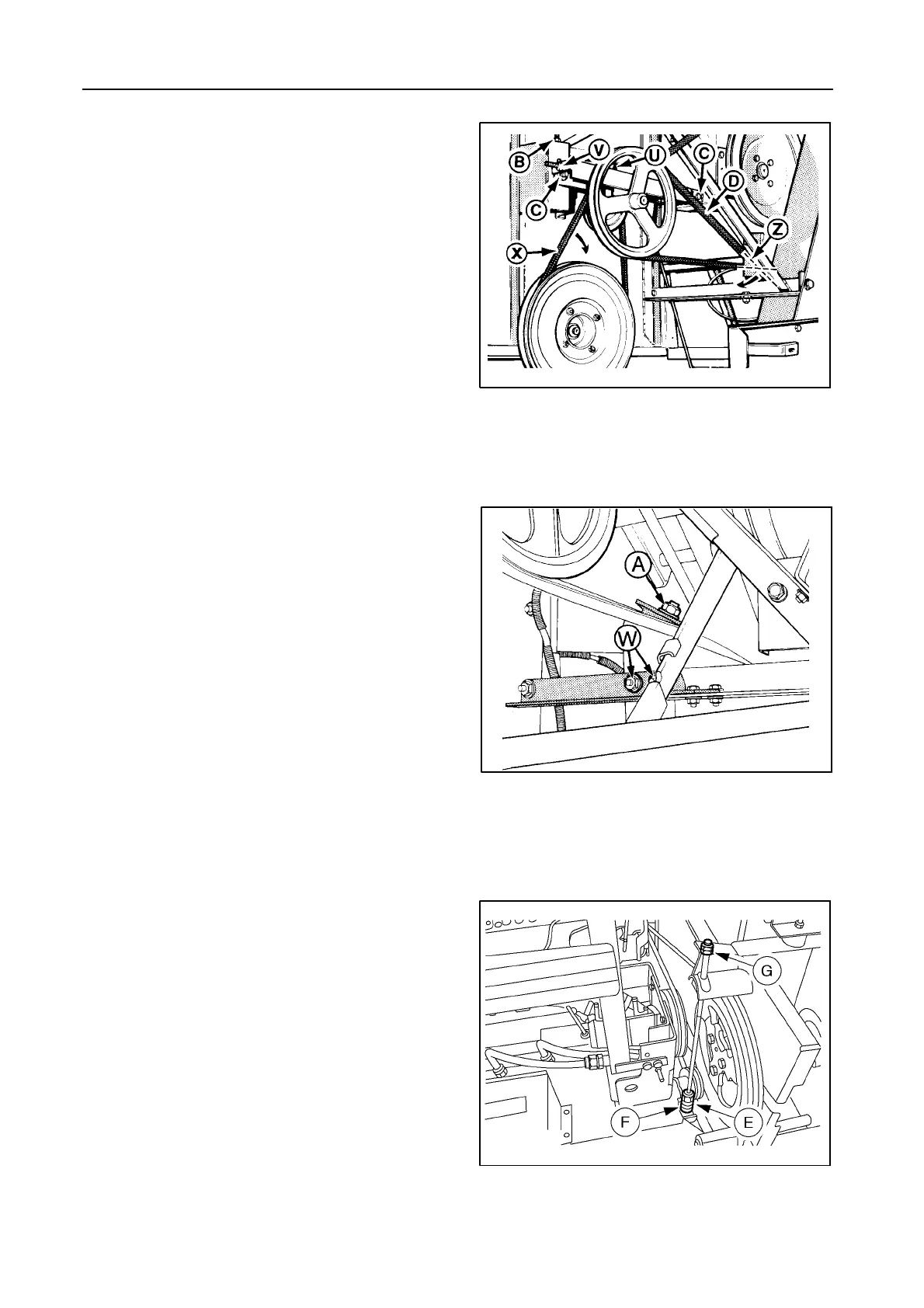

U. Loosen bolts W and adjust pulley A and its

support slightly downwards [forming an angle of

approximately 35° with the straight line between

the two pulleys -- front pulley upper side and rear

pulley lower side (view from the rear)], so that a

clearance of 2 to 3 mm exists between both belt

halves. Retighten bolts W .

22 STRAW WALKER DRIVE BELT -- Figure 33

The belt tension is correct when the belt can be

deflected 5 mm when applying a force of 41 N

halfway between the pulleys at X .

Adjust with rod B after loosening bolts C.

Retighten bolts C.

NOTE:

Adjustments of the straw walker drive belt and

the straw walker intermediate shaft drive belt

should be carried out together.

23 COOLING SYSTEM INTERMEDIAT E SHAFT

DRIVE BELT -- Figure 35

Correct belt tension:

Spring length E = indicator plate length F.

Adjust with nut G.

33

34

42920

21082

35

54738

Loading...

Loading...