ADJUSTMENTS AND MAINTENANCE

5-44

6. Continue pumping until the force needed remains

more or less constant. This allows the fuel to be

drawn into the injection pump.

7. Models TX68-68

PLUS

only:

Press the fuel lift pump piston down and firmly

tighten knurled knob C.

NOTE:

If the engine does not start after performing

the above procedure, it will be necessary to

bleed the fuel injector lines while starting the

engine.

This will allow any air to escape that may be in

the high pressure part of the fuel system.

Take all necessary safety precautions when

working on the engine. Do not bleed the lines

when the engine is warm.

Fuel injection pump and injectors

As the fuel injectors and fuel injection pump have to

be set very accurately on specialized equipment, we

strongly recommend that any repairs on these parts

are carried out by your New Holland dealer.

COOLI NG SYSTEM

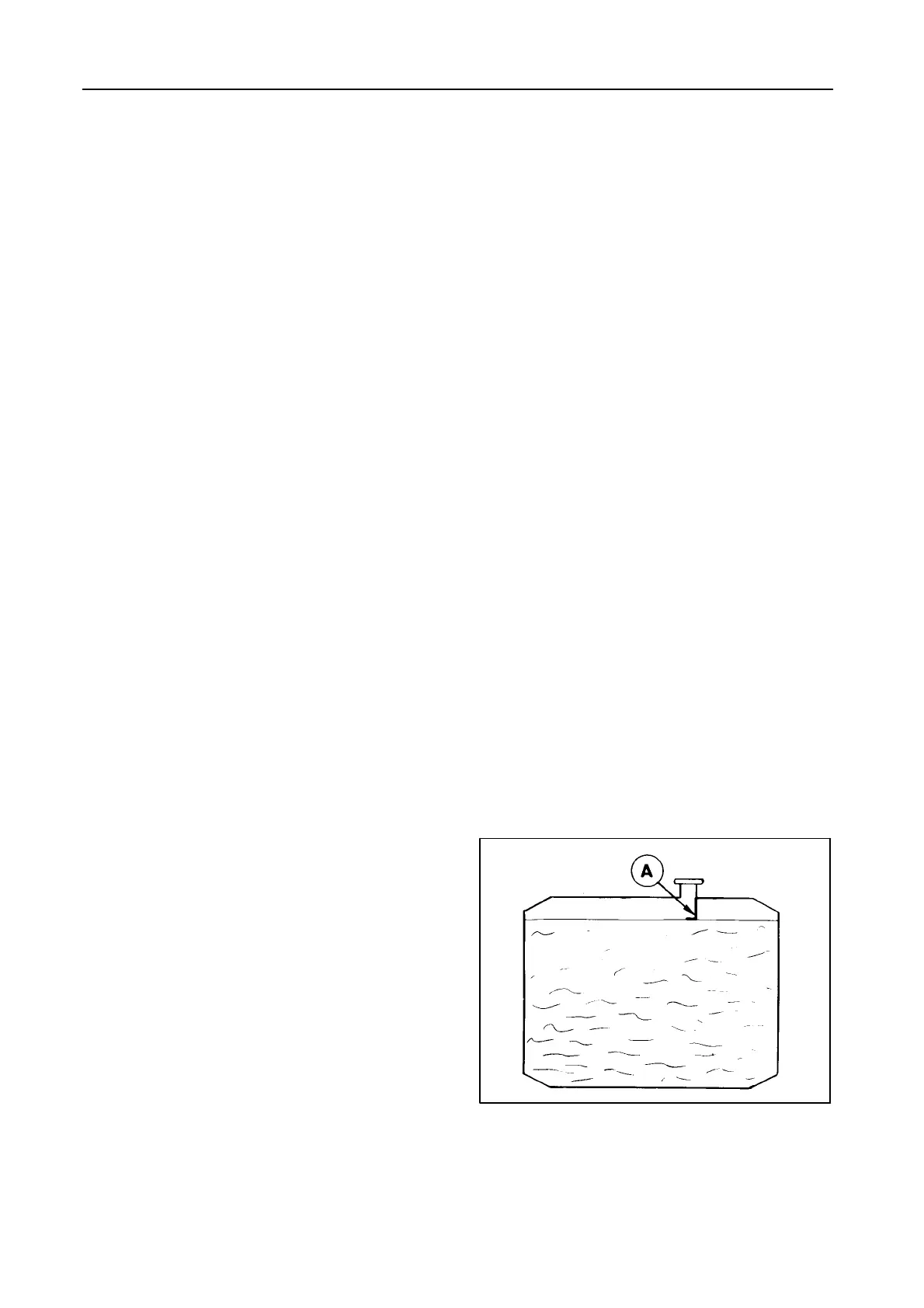

Coolant level -- Figure 82

Daily check the radiator coolant level on the level indi-

cator A when the engine is cold.

ATTENTION:

Under no circumstances should the engine be

started without water in the cooling system.

If the temperature rises too high during operation, or

if the audible alarm sounds, stop the engine immedi-

ately and locate the cause (coolant level, oil level, fan

and rotary dust screen belt tension, dirty radiator or

rotary dust screen, etc.). Refer to Section 6 - TROU-

BLESHOOTING.

82

51514

Loading...

Loading...