SECTION 6

6-3

THRESHING, SEPARATION AND CLEANING

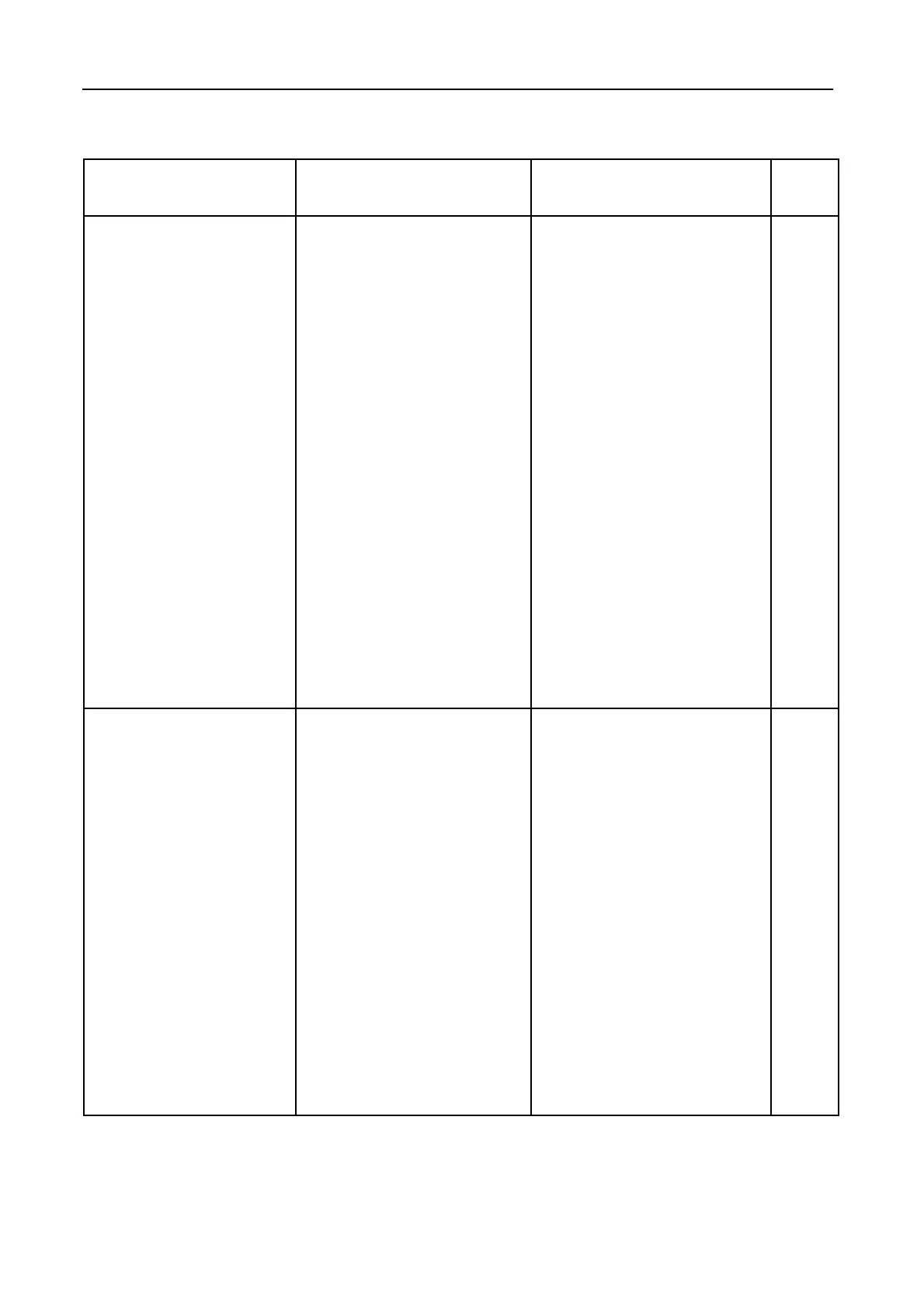

CONCERN POSSIBLE CAUSE CORRECTION PAGE

Excessive cracked grain in

tank.

Drum speed too high. Reduce drum speed and/or open

concave slightly.

4-27

Excessive tailings. See the concern described under

‘‘Excessive tailings’’, below.

--

Concave clogged, or openings

blocked by de-awning plates.

Clean concave and open de-awn-

ing plates.

4-32

Concave not parallel to drum. Adjust concave parallel to the

drum.

4-28

Grain being cracked in elevator. Adjust grain elevator chain ten-

sion.

5-25

Clearance between drum and

concave too small.

Increase concave clearance.

Reduce drum speed slightly.

4-28

Uneven feeding, or wads enter-

ing drum.

Adjust straw elevator chain.

Check feed auger height and

retractable finger adjustment.

4-18

Separate

Header

Manual

Not enough material entering

combine.

Lower header and increase

ground speed.

--

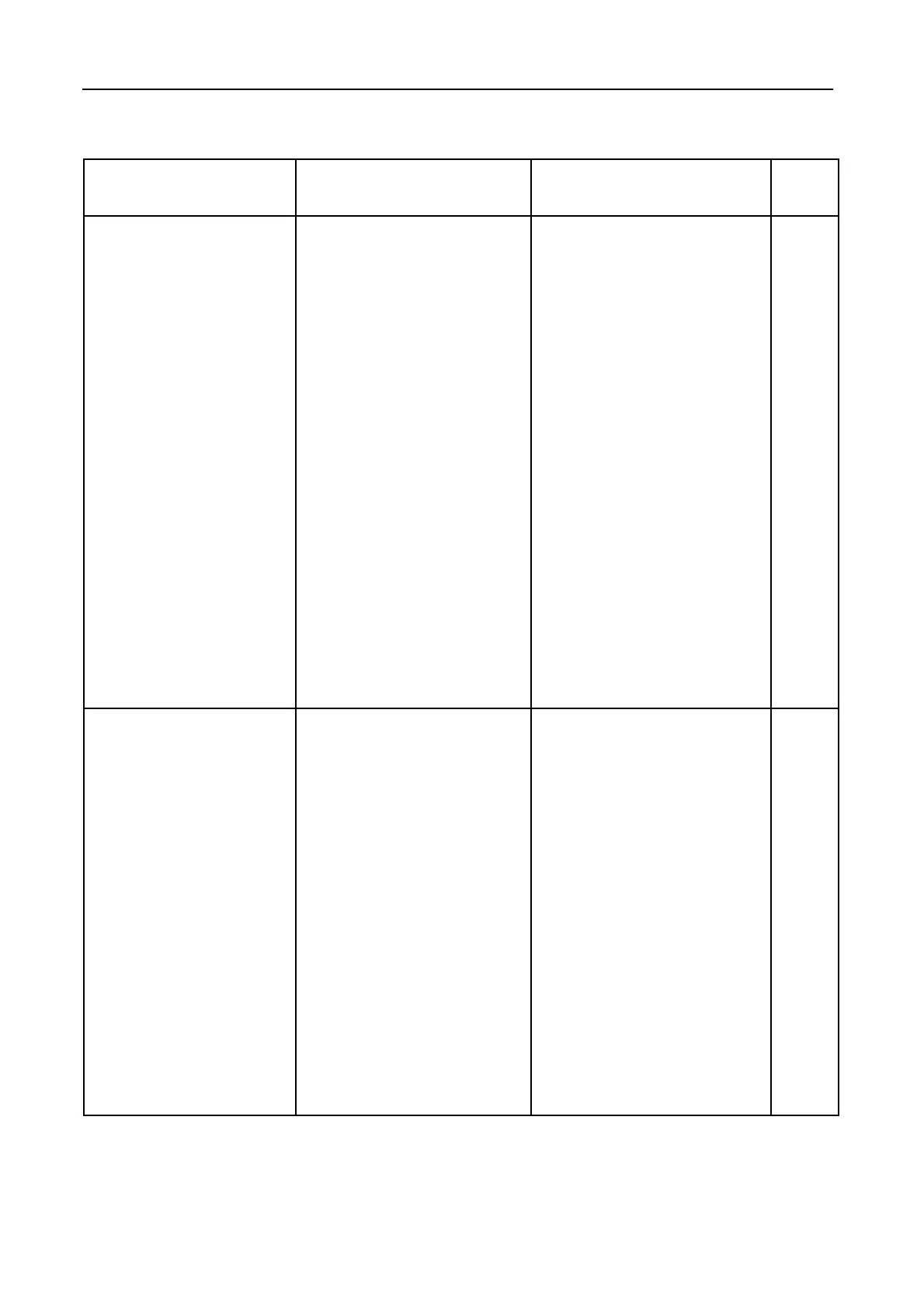

Grain loss over Twin Flow

rotor.

Straw walkers running at incor-

rect speed.

Check speed of intermediate

shaft. Correct speed is 800 rpm

(with empty machine).

--

Straw walkers overloaded due to

excessive ground speed.

Reduce ground speed to de-

crease amount of material enter-

ing combine. Raise header. In-

crease concave-to- drum clear-

ance if straw walkers have be-

come clogged due to the straw be-

ing broken up excessively. (It may

be necessary to reduce concave-

to-drum clearance if overloading

is the result of imcomplete thresh-

ing. In this case, it may be desir-

able to increase the drum speed).

--

Loading...

Loading...