ADJUSTMENTS AND MAINTENANCE

5-2

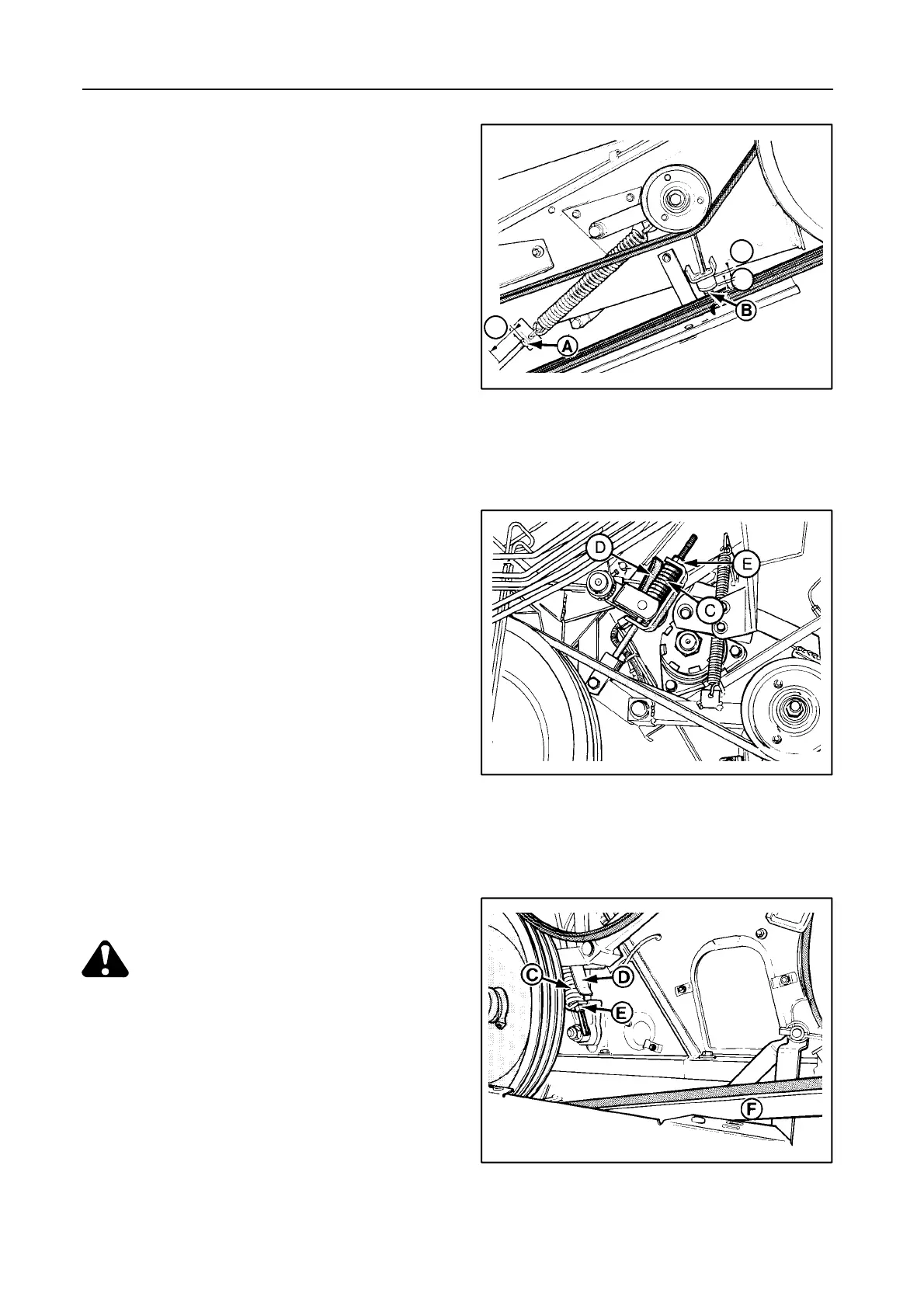

1 HEADER DRIVE BELT -- Figure 2

Correct belt tension:

X = 100 mm for 1HC belt

X = 155 mm for 4HB belt

Adjust with nuts A.

Y should be 0 mm. Adjust with nuts B.

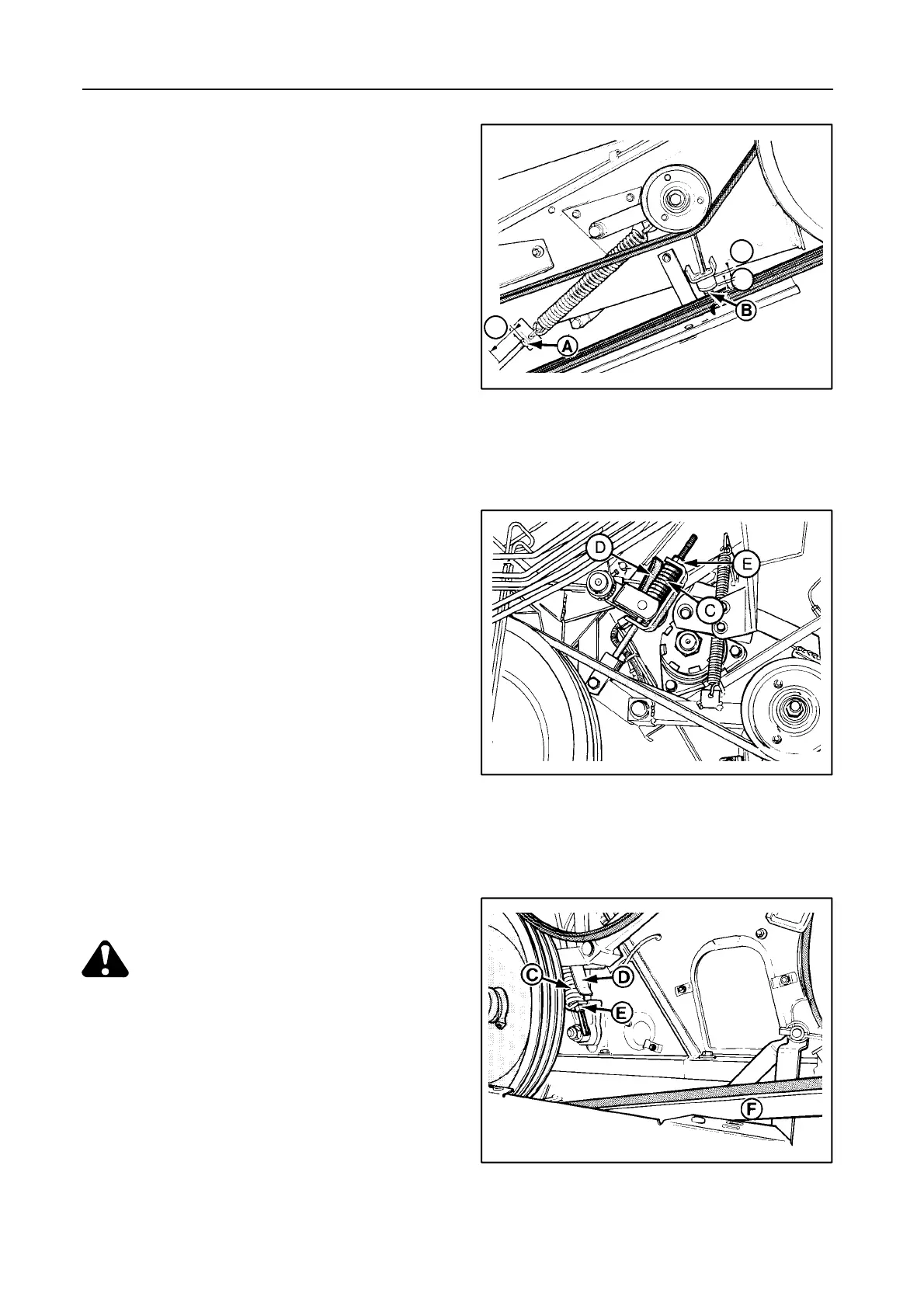

2 STRA W ELEVATOR AND HEADER ENGAG-

ING BELT

Models TX62-63 -- Figure 3

Models TX64

PLUS

-65

PLUS

-66-67-68-68

PLUS

--

Figure 4

Correct belt tension (in engaged position):

Spring length C = indicator plate length D.

Adjust with nuts E.

Adjust the belt guide F so that it is at a maximum

distance of 7 mm from the engaged belt, through-

out the belt guide circumference.

Proceed as follows to check and adjust the ten-

sion of the straw elevator and header engaging

belt, of the threshing mechanism engaging belt

(item 4) and of the unloading system engaging

belt (item 3).

CAUTION:

For header, threshing and unloading

system:

Make sure nobody is near the combine

when disengaging the drive belt, even

when the engine is not running!

Make sure nobody is near the combine

when restarting the engine as some com-

ponents may rotate for a while.

2

3

30214

30215

4

55036

TX64

PLUS

-65

PLUS

-66-67-68-68

PLUS

Y

Y

X

TX62-63

Loading...

Loading...