SECTION 2

2-3

3. SEPARATION -- Figure 2

The beater 9, with beater concave 10, strips the straw

from the drum and guides it to the rotary separator 11

and concave 12, which further separates the grain

from the straw.

The straw retarding curtain 13 prevents the rotary

separator from throwing the straw too far onto the

straw walkers 14.

A Straw Flow beater 15 [if installed] improves the

straw transport towards the straw walkers and en-

ables a smoother flow of material in heavy crop condi-

tions.

The straw walkers 14 oscillate, lift and tumble the

straw, permitting the remaining grain to fall through

the walkers and slide down the walker return pans

onto the rear of the grain pan 8.

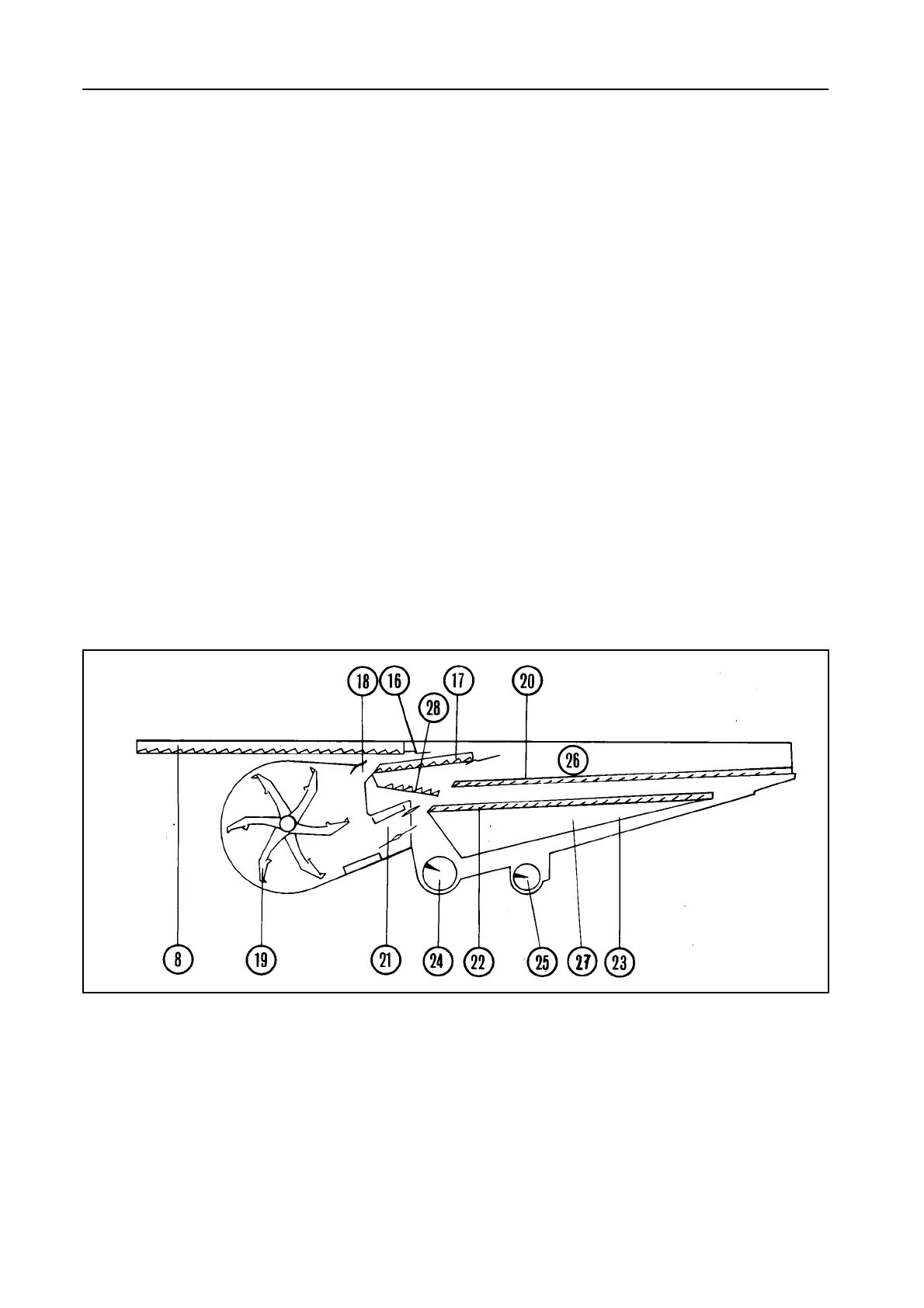

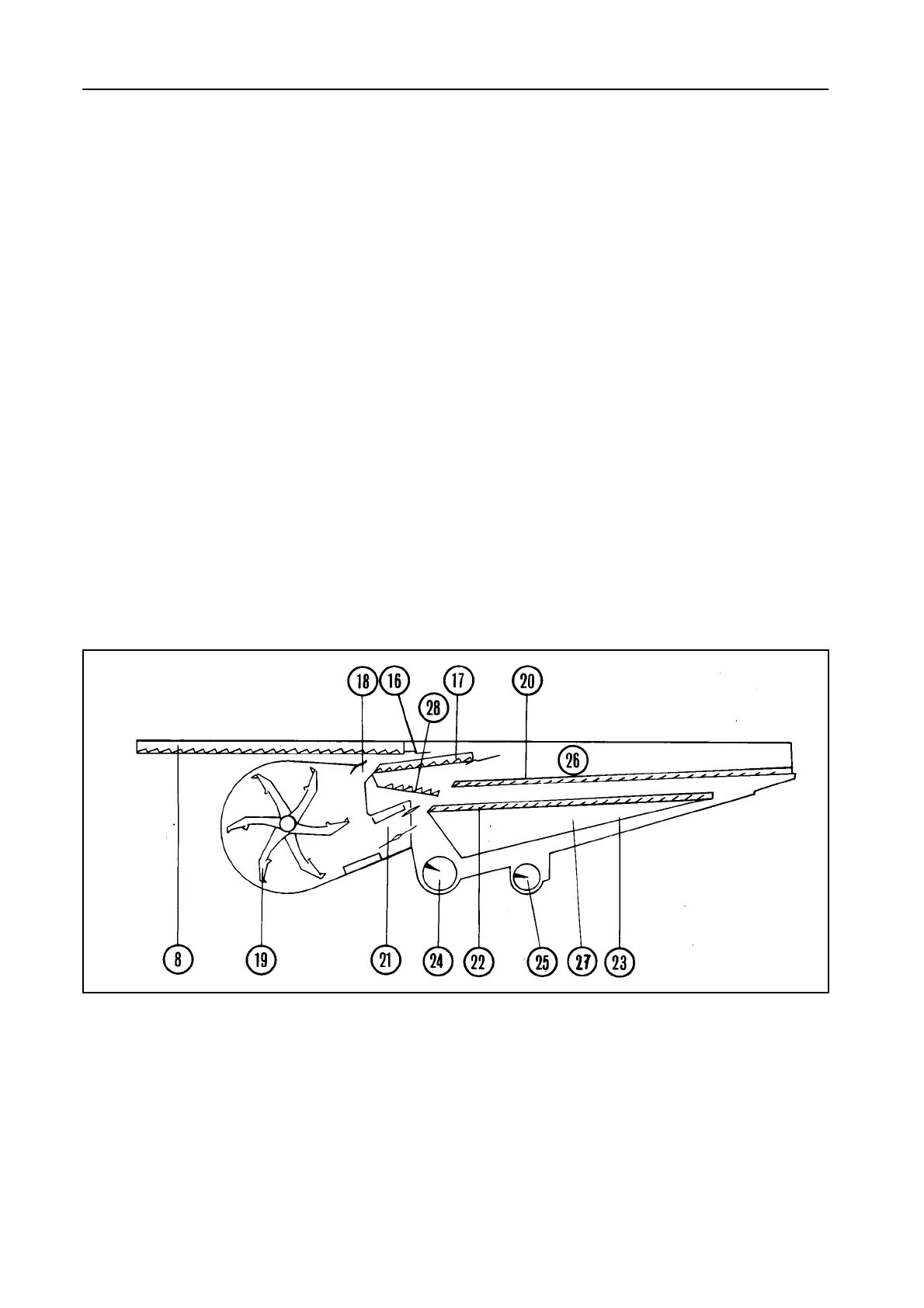

4. CLEANING -- Figures 3 and 4

Units with self-levelling cleaning shoe

The grain and chaf f on the grain pan 8 are transported

to the rear by the reciprocating action of the exclusive

self-levelling cleaning shoe. An electrical actuator en-

sures that the cleaning shoe automatically remains

horizontal in the transverse axis of the machine, even

when operating on side slopes up to 17%. This inno-

vation increases the capacity of the cleaning shoe

considerably when operating in hilly conditions.

Units with fixed cleaning shoe

As the cleaning shoe is not self-levelling, operation on

slight slopes is made possible by the installation of

hillside dividers on the grain pans and the upper sieve.

Hillside dividers are installed as standard equipment

on the grain pan 8 where they ensure an even distri-

bution of the material before it reaches the short grain

pan 28.

3

51590

Loading...

Loading...