CHAPTER 13 TROUBLESHOOTING

COPYRIGHT

©

2002 CANON INC. 2000 CANON iR1600/iR2000 REV.1 JAN. 2002

13-27

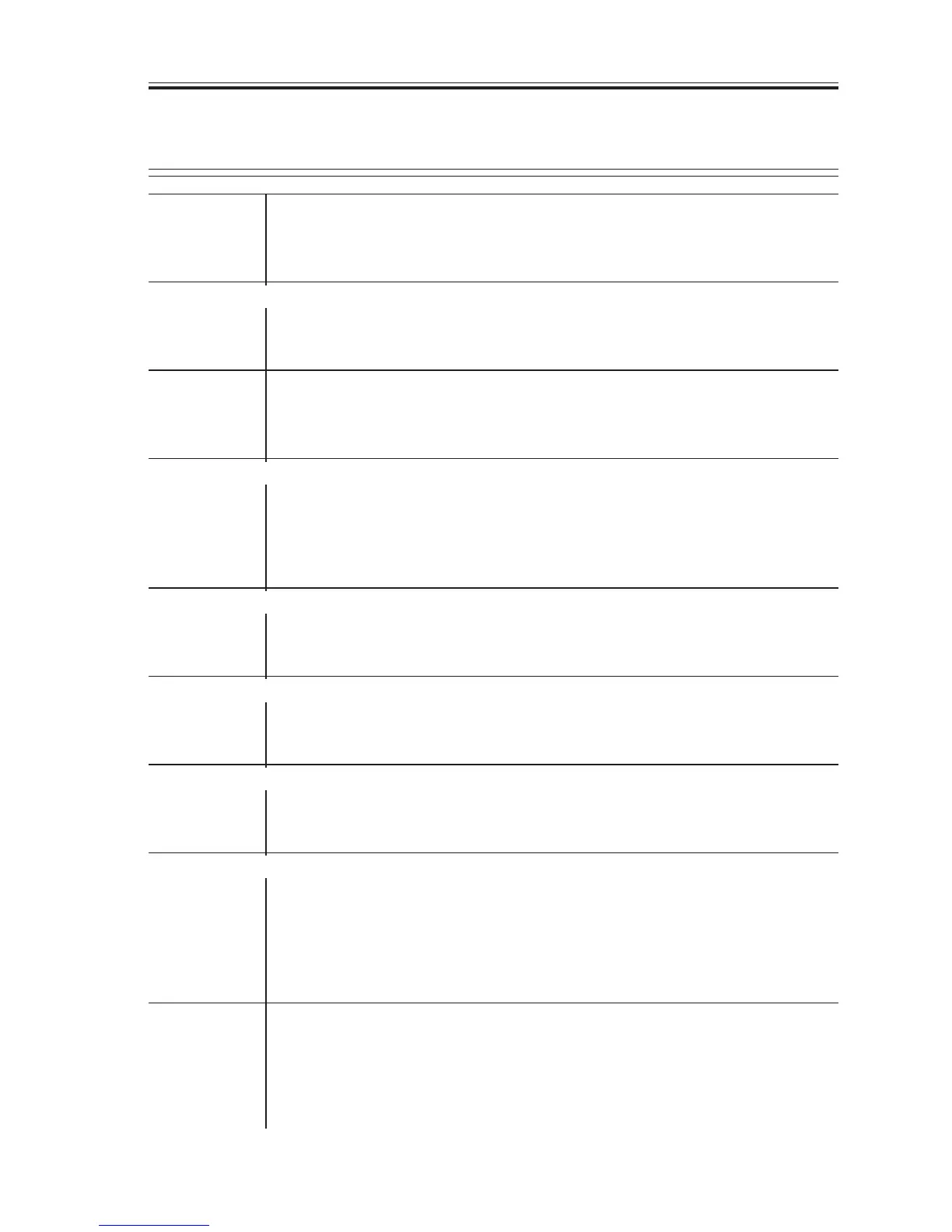

3.3.10 The copy has white strips. (feeding direction)

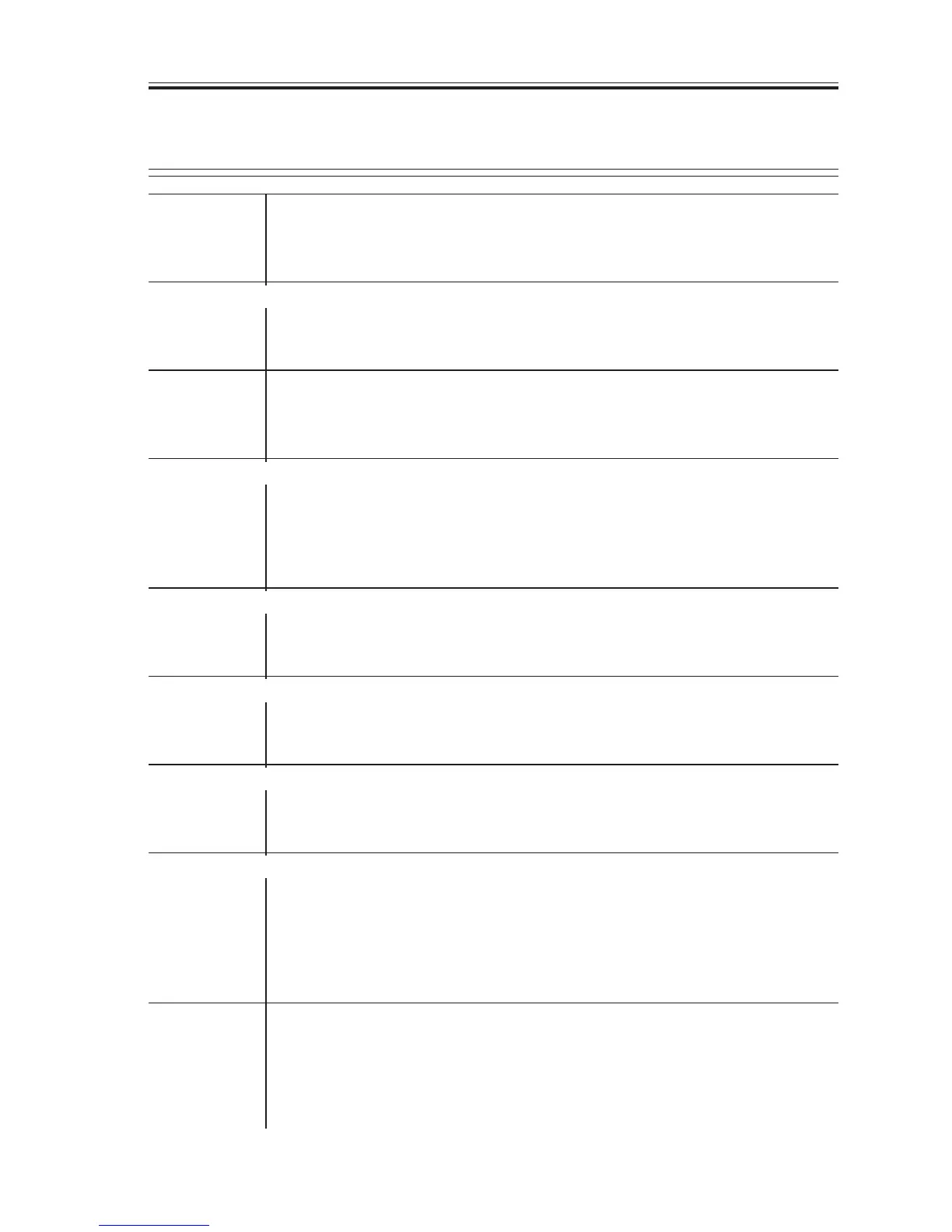

3.3.11 The copy has white lines. (feeding direction)

Machine state

1) Execute ‘PRINT’. Is the output image normal? (See 5.5.5 of Chap-

ter 13.)

YES: Go to step 6.

Developing assembly

2) Is the coating of toner on the developing cylinder even?

NO: Rotate the developing cylinder to see if the coating becomes even.

If not, replace the developing assembly.

Drum unit

3) Is there a scratch or black line in the peripheral direction of the

surface of the photosensitive drum?

YES: Replace the drum unit.

Transfer charging roller, Pre-transfer static eliminator

4) Is the transfer charging roller or the pre-transfer static eliminator

coated with foreign matter?

YES: Clean the transfer roller or the transfer static eliminator. If the fault

is not corrected, replace the transfer charging roller or the transfer

static eliminator.

Fixing assembly

5) Execute fixing roller cleaning in user mode. Is the fault corrected?

YES: End.

NO: Replace the fixing assembly.

Gain auto adjustment

6) Execute gain auto adjustment. Is the problem corrected? (See 2.3.2

of Chapter 13.)

YES: End.

Contact sensor, Standard white plate

7) Clean the rod lens array of the contact sensor and the copyboard

glass (standard white plate). Is the fault corrected?

YES: End.

Shading position correction

8) For shading position correction in service mode, set a level between

‘90’ and ‘72’ for ‘6 SCANNER>7 CCD>parameter ‘19’. Is the fault

corrected?

YES: End.

NO: Replace the copyboard glass. If the fault cannot be corrected, go to

step 9).

CS unit

9) Are the CS unit and the spacers mounted correctly? Also, are the

spacers free of water?

YES: Replace the contact sensor.

NO: Correct the fault. If the fault cannot be corrected, replace the faulty

part.

Loading...

Loading...