ENGINE

®

@

89

warpage. Replace the cylinder head cove r if the

gasket

su

rf

ace is warped

to

or

beyond the service

limit listed

in

Table I.

4. Disassemb

le

and inspcctthe rocker arms

as

de·

scribed

in

this chapter.

Camshaft Inspection

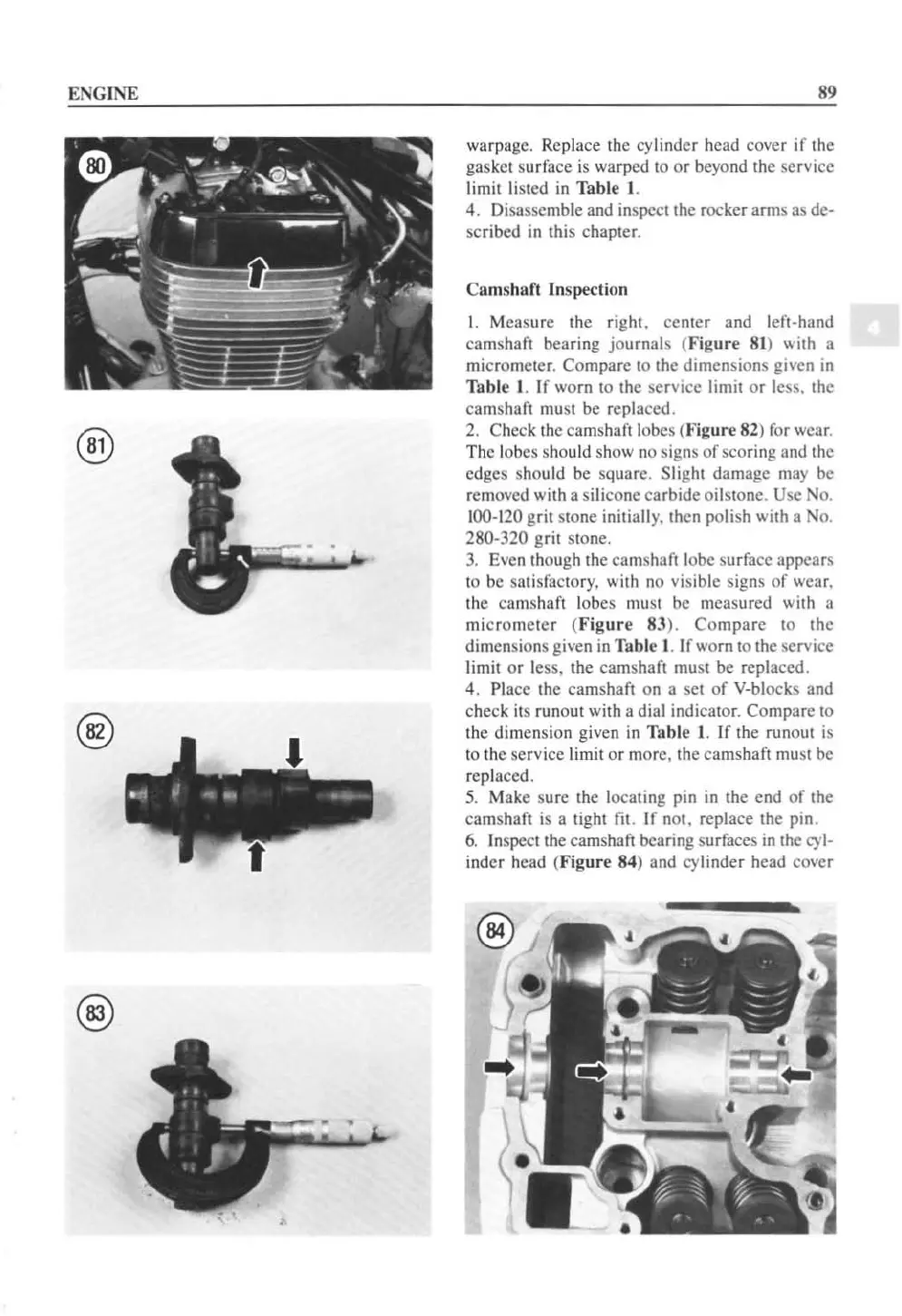

1.

Measure the right. center and left·hand

camshaft bearing journals (Figure

81

) with a

mi

crometer. Compare

to

the dimensions given

in

Table

l.

If worn

to

the service limit or

le

ss. the

camshaft

mu

st be replaced.

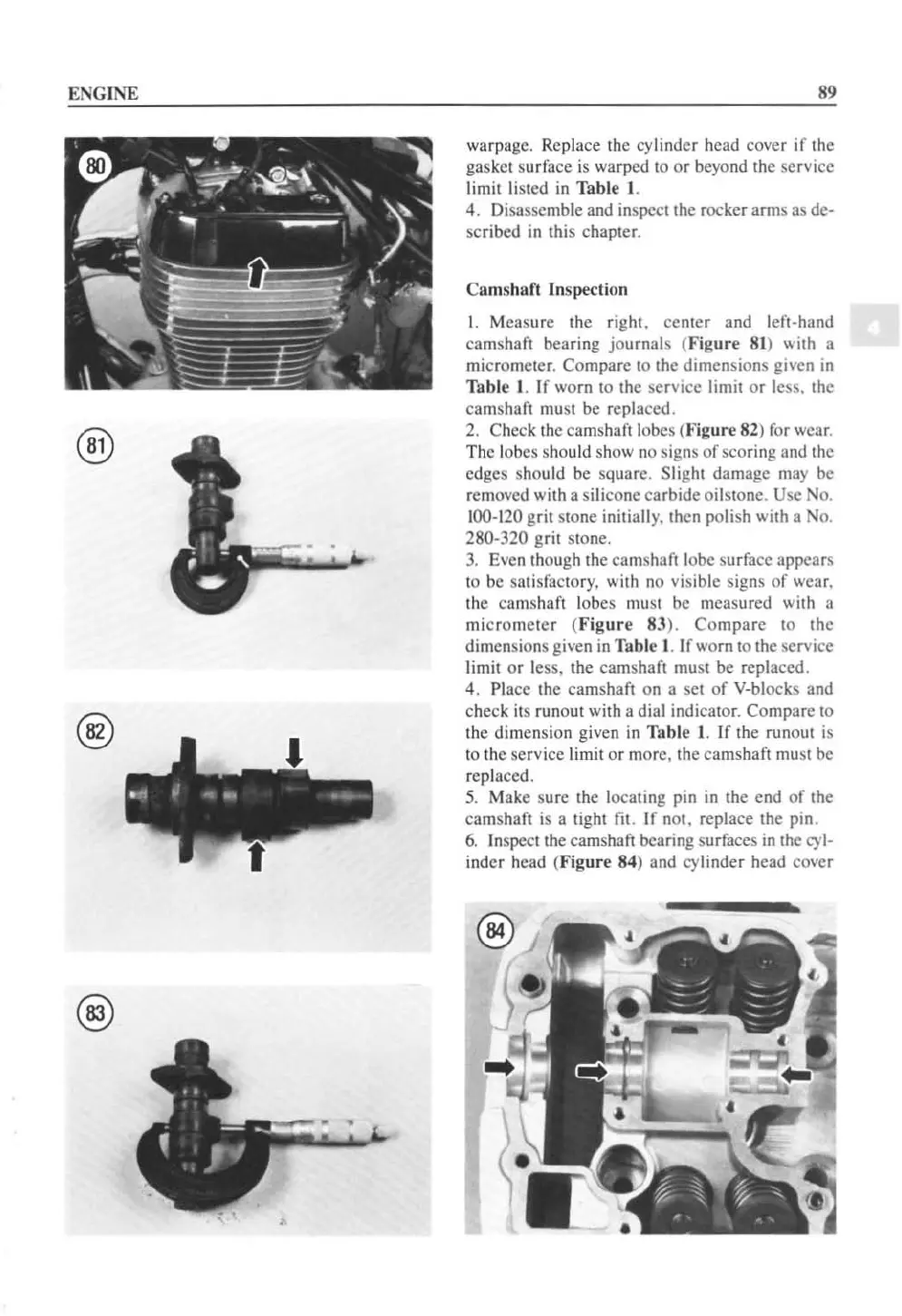

2.

Check the camshaft lobes (I"igure 82)

for

wear.

Th

e lobes should show

no

signs

of

scoring and the

edges should be square.

Sl

ight damage

may

be

removed with a

si

li

cone carbide oilstone. Use No.

100·120

grit stone initiall

y.

then polish with a No.

280-320 grit stone.

3.

Even though the camshaft lobe

su

rfa

ce

appears

to

be

satisfactory, with

no

visible signs

of

wear,

the cams

ha

ft

lobes must

be

measured with a

micrometer (

Figure

83). Compare to the

dimensions given

in

Table I. If worn

to

the service

limit

or

less, the camshaft must be replaced.

4. Place the camshaft on a set

of

V-blocks and

check its runout with a dia l indi

ca

tor.

Compare

to

the dimension given

in

Table

l.

If the runout is

to

the

se

rvice lim

it

or more. the camshaft must

be

replaced.

5. Make sure the locating pin

in

the end

of

the

camshaft is a tight fit. If not. replace the pin.

6.

In

spect the cams

haft

bearing surfaces

in

the cyl·

inder head (Figure 84) and

cy

linder head cover

®

Loading...

Loading...