284

REAR HUB

In

spection

In

spect each wheel bearing before removing

it

from the wheel hub.

GlUTtON

Do not remove the wheel bearings

for

inspection purposes as they will be

damaged

(Juri

ng the remol'al process.

RemOl'e

wheel bearings only

if

they are

to

be replaced.

l. P

er

form Sleps 1

·7

of

Disassembly

in

this

chapter.

2.

Turn each bearing

by

hand. Make sure

the bearings turn smoothl

y.

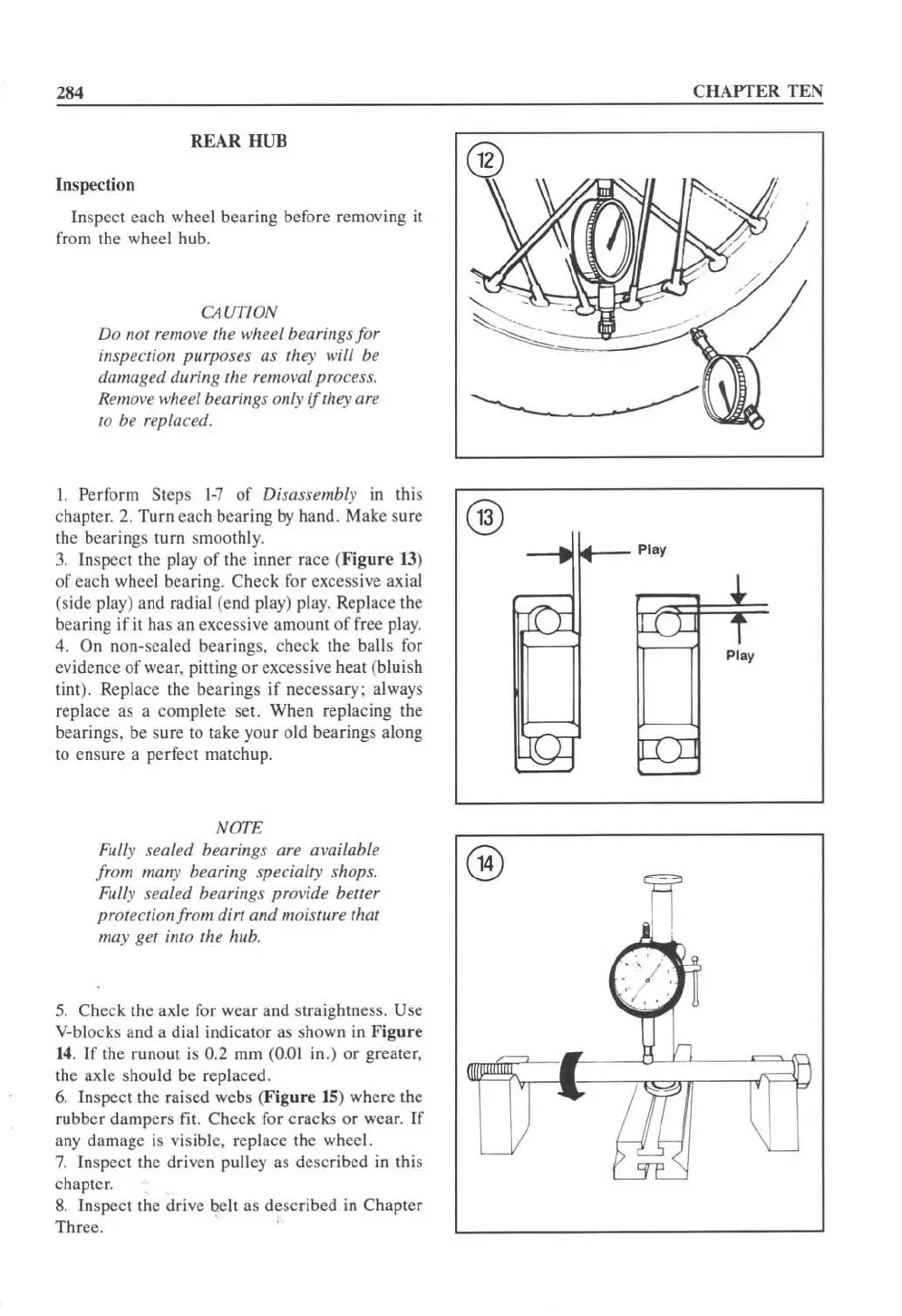

3.

In

spect the play of the inner race

(F

igure

13

)

of

each wheel bearing. Check for excessive axial

(side play) and radial (cnd play) play. Replace the

bearing

if it has

an

excessive amount of frec play.

4.

On non-scaled bearings. check the ba

ll

s for

evidence

of

wear, pitting

or

excessive heat (bluish

tint). Replace the bearings

if

necessary: always

rcplace as a complcte

SCI. When replacing the

bearings. be sure to take

yo

ur old bearings along

to ensure a perfect matchup.

NOTE

Fully

sealed bearings are available

from many bearing specialty shops.

Fully sealed bearings provide better

protecliollfrom dirt and moisture that

may

get into the hub.

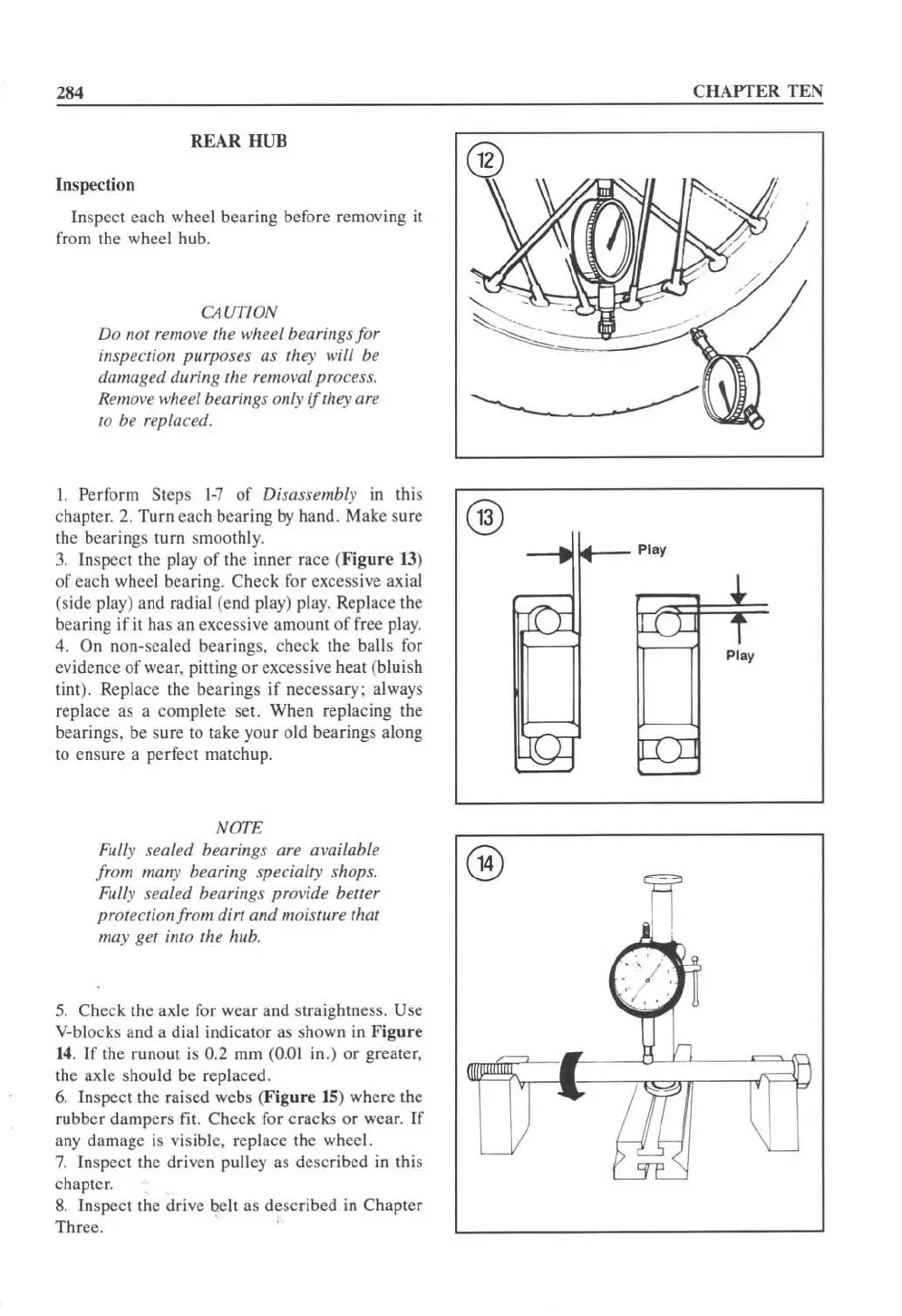

5.

Check the axle for wear and straightness. Use

V-blocks and a dial indicator as shown

in

Figure

14

. If the runout is 0.2 mm (0.01 in.)

or

greater,

the axle should

be replaced .

6.

Inspect the rai sed webs (

Figur

e

IS

) where the

rubber dampers fit. Check for cracks

or

wear.

If

any damage

is

visible, replace the wheel.

7.

In

spect the driven pulley as described

in

this

chapter.

8.

Inspect the drive

be

lt

as described

in

Chapter

Three.

CHAPTER TEN

@

Play

Play

®

Loading...

Loading...