6

FASTENERS

The materials and designs

of

the various

fa

steners used on

yo

ur Suzuki are not arrived at

by chance or accident.

Fa

stener design determines

the

type

of

lool required to work the

fas

tener. Fas-

tener material is carefully selected to decrease the

possibility

of

physical failure.

Thr

ea

ds

Nuts. bolls a

nd

screws arc manufactured

in

a

wide range of thread pallcrns. To join a

nu

t and

bolt. the diameter of the bolt and the diameter

of

the hole

in

the

nUl

mu

st

be

the same. It is

ju

st as

important that the threads on both

be

properly

matched .

The best way to tell

if

the threads on 2

fas

teners

are matched

is

to turn the n

Ul

on the bo

lt

(or

the

bolt into

th

e threaded hole in the piece

of

equipment), with your fingers o

nl

y.

Be sure both

pieces

are

clean.

If

much force

is

required. check

the thread co

nd

ition on each fastener. If the thread

condition

is

good. but the

fas

tener

jam

s. the threads

are not compatible. A thread pitch gauge (

Figure

7) can also

be

used to determine pitch. Suzuki

motor

cycl

es are manufactured with metric standard

fastener

s.

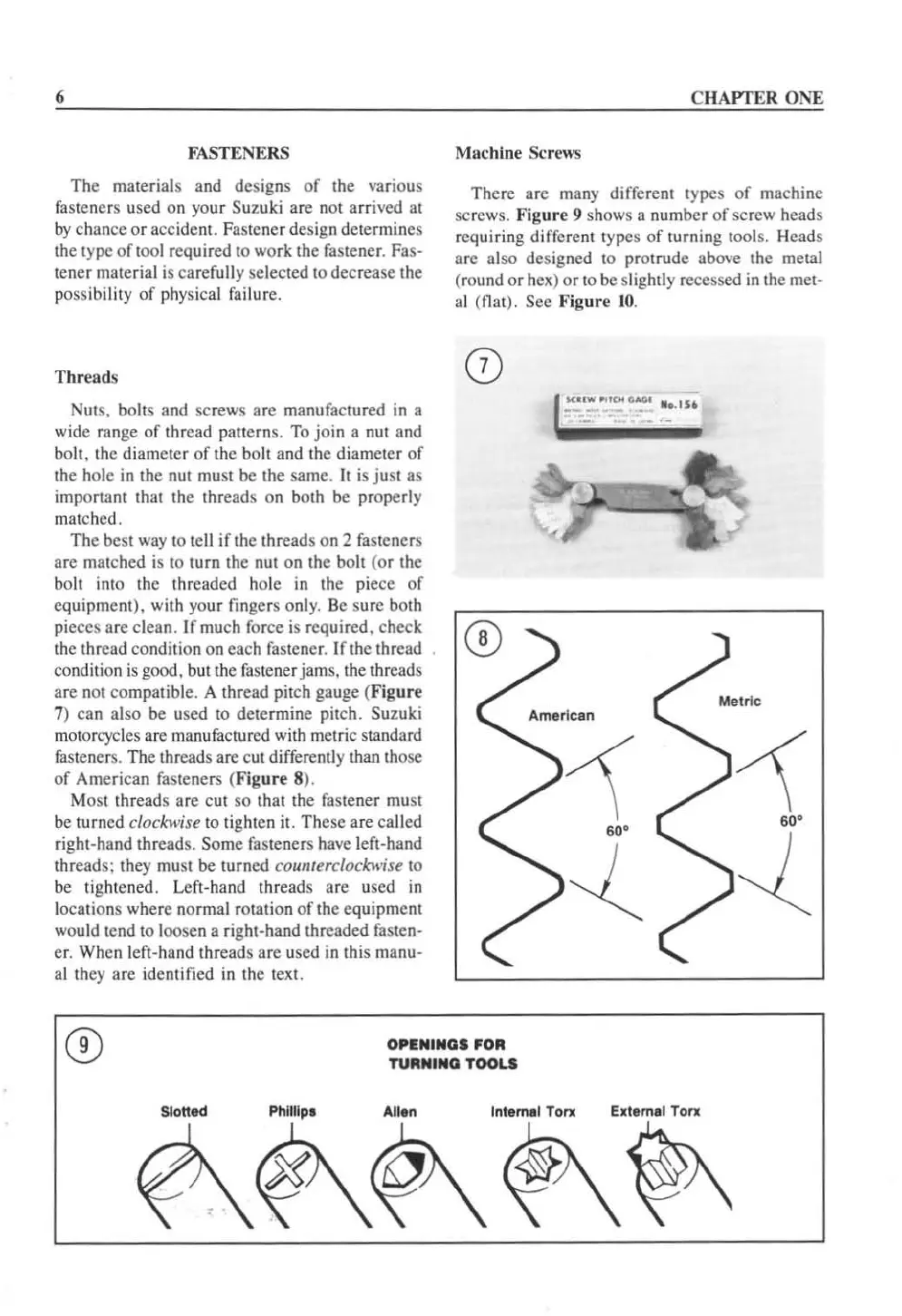

The threads are c

ut

differently than those

of

American fasteners (

Figu

re 8).

Most th reads

are

cut so that the fastener must

be turned

clockwise to tighten it. These

are

ca

ll

ed

right·hand threads. Some fasteners have left-hand

threads; they must be turned coumerclockwise to

be tightened. Left·hand

thr

eads

are

used

in

locations where n

or

mal rotation of the equipment

would tend to loosen a r

ig

ht-hand threaded fasten-

er. When left-hand

thr

eads are u

se

d

in

this ma

nu

-

al they

arc

identified in the text.

CHAPTER ONE

Machi

ne Screws

There arc many different types

of

machine

screws. Fig

ur

e 9 shows a number

of

scr

ew

heads

requiring

diff

erent types of turning tool

s.

Heads

are

also designed to protrude above the metal

(round

or

hex)

or

to

be

s

li

gh

tl

y recessed

in

th

e mel-

al

(nat). See

Figure

10

.

i

.0·

~

i

.0

·

~

OPENINGS

'-OR

TURNING

TOOLS

Slotted Phillip. Allen

Intemll

Ton:

~~~

Loading...

Loading...