210

by

the aiternalOr is rectified to direct

cur

ren!. The

vo

ltage regulator maintains the voltage to the

cleclrical load (lights. ignition. etc.)

at

a constant

voltage regardle

ss

of

varia lions

in

cngine speed and

load.

Chargi

ng System

Output

Test

Whenever charging system trouble

is

suspected.

make sure the battery is fully charged and in

good

condition before going any further. Clean and test

the banery as described

in

Chapter Three. Make

sure all elect

ri

cal connectors are tight and free

of

corrosion.

I. Star! the engi

ne

and let

it

reach normal

operat

in

g temperature. Shut off the engine.

2. Remove the seat as described

in

Chapler

Twelve.

3.

Remove both the right· and left-hand frame

cove

rs (Figure 2),

4. Conncct a portable tachometer following the

manufacturer's instructions.

5.

Turn the headlight

dimmer

switch to the

HI

position.

6.

Start the eng

in

e and let

it

id

le.

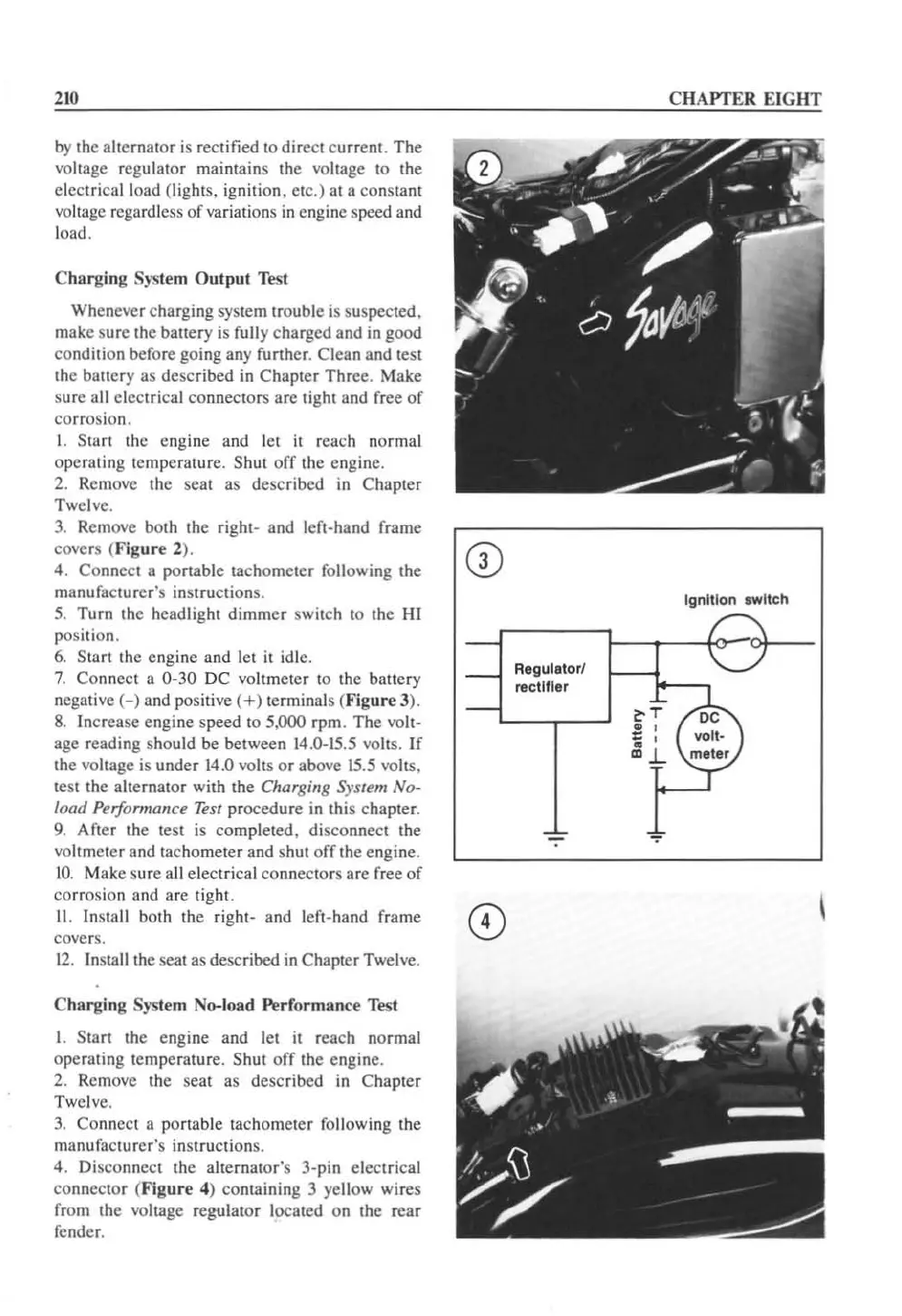

7.

Connect a 0-30 DC voltmeter to the battery

negative

(-)

and positive

(+)

terminals (

Figure

J).

8.

Increase engine speed to 5,000 rpm. The volt-

age reading should be between

14

.0-15.5 volts. If

the voltage is under 14.0 volts

or

above

15

.5 volts.

test the alternator with the Charging System No-

load

Performance

Test

procedure in this chapter.

9.

After the test is completed, disconnect the

voltmeter and tachometer and shut

off

the engine.

10.

Make sure all electrical connectors are

fr

ee

of

corrosion and are tight.

11.

Install both the right- and left-hand frame

covers.

12

.

In

sta

ll

the seat as described

in

Chapter Twelve.

Ch

arging

System No-l

oad

Performance Test

1.

Start the engine and let

it

reach normal

operating temperature. Shut

off

the engine.

2. Remove the seat as described

in

Chapter

Twelve.

3.

Co

nn

ect a portable tachometer following the

manufacturer's instructions.

4. Disconnect the alternator's 3-pin electrical

connector (

Figure

4) containing 3 yellow wires

from the voltage regulat

or

located on the rear

fender.

Regutatorl

rectilier

CHAPTER EI

GHT

tgnltlon

_I

tch

Loading...

Loading...