82

faced

ma

ll

et. If necessary. gelllly pry the head

~

loose with a broad-lipped screwdriver.

~

CAUTION

Remember Ihe

COOlillgjillS

are/ragile

and

may he damaged

if

tapped 011

or

prittl

/00

hard. Never use a metal

hammer.

28.

Liflthe

cy

linder head

st

raight up and

off

the

cyli

nd

er and crankcase studs. Guide the camshaft

chain through the opening in the cylinder head and

relic the wire

to

the exterior

of

the engine. This

will

prevent the drive chain from falling down into

the crankcase.

29. Remove the

cy

lind

er

head gasket and discard

it. Don', lose the locating dowels.

30.

Inspect the cylinder head cover, the

cy

li

nder

head and camshaft

as

described in this chapler.

Installation

1.

If removed,

in

stall the locating dowel in the

cy

linder.

2.

Insta

ll

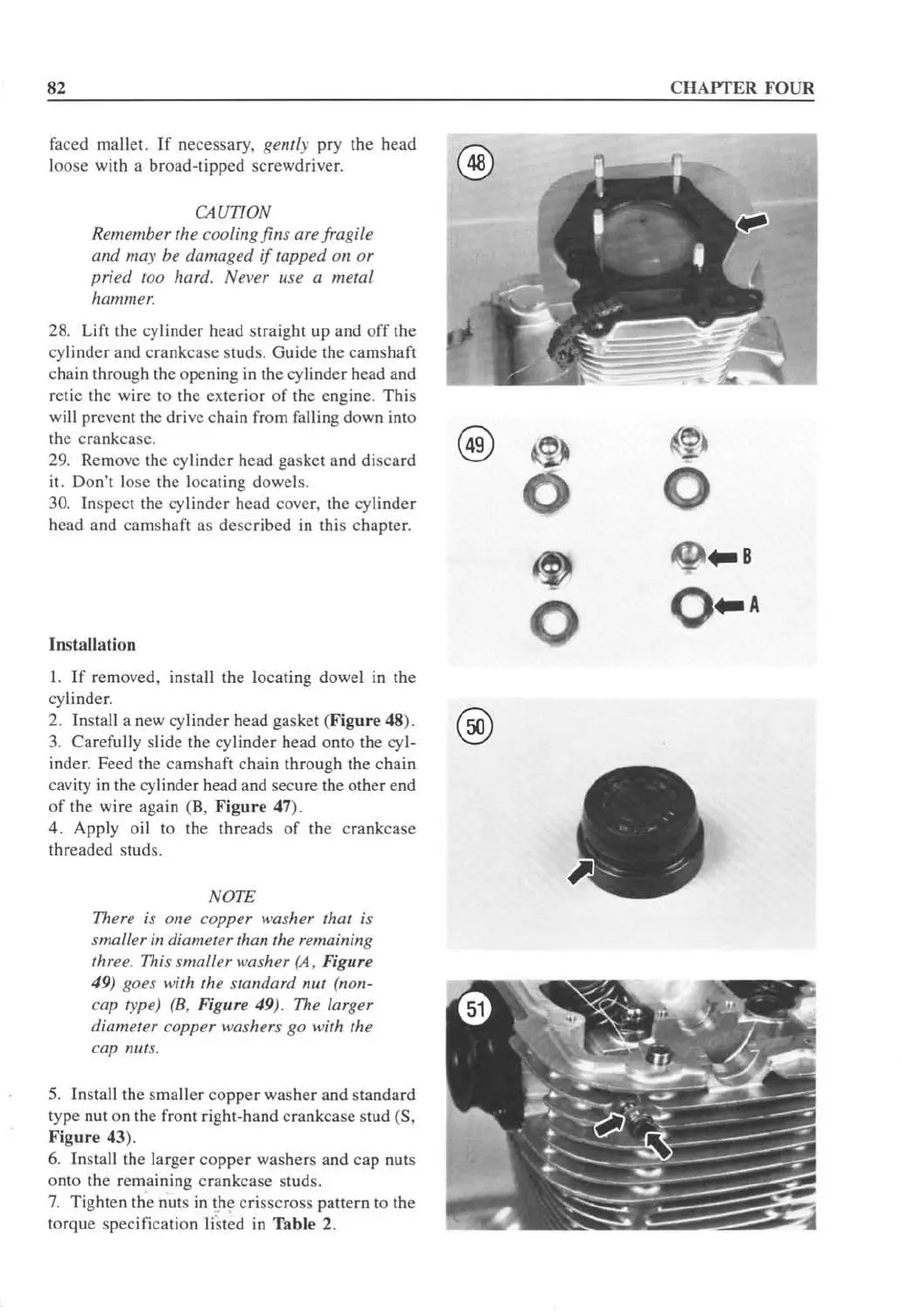

a new cylinder head gasket (

Figure

48).

f"5(i\

3.

Carefully slide the cylinder head onto the cyl-

~

inder. Feed the camshaft chain through the chain

cavity

in

the cylinder head and secure the other end

of

the wire again (

B,

Figure

47).

4. Apply oil to the

th

reads of the crankcase

threaded studs.

NOTE

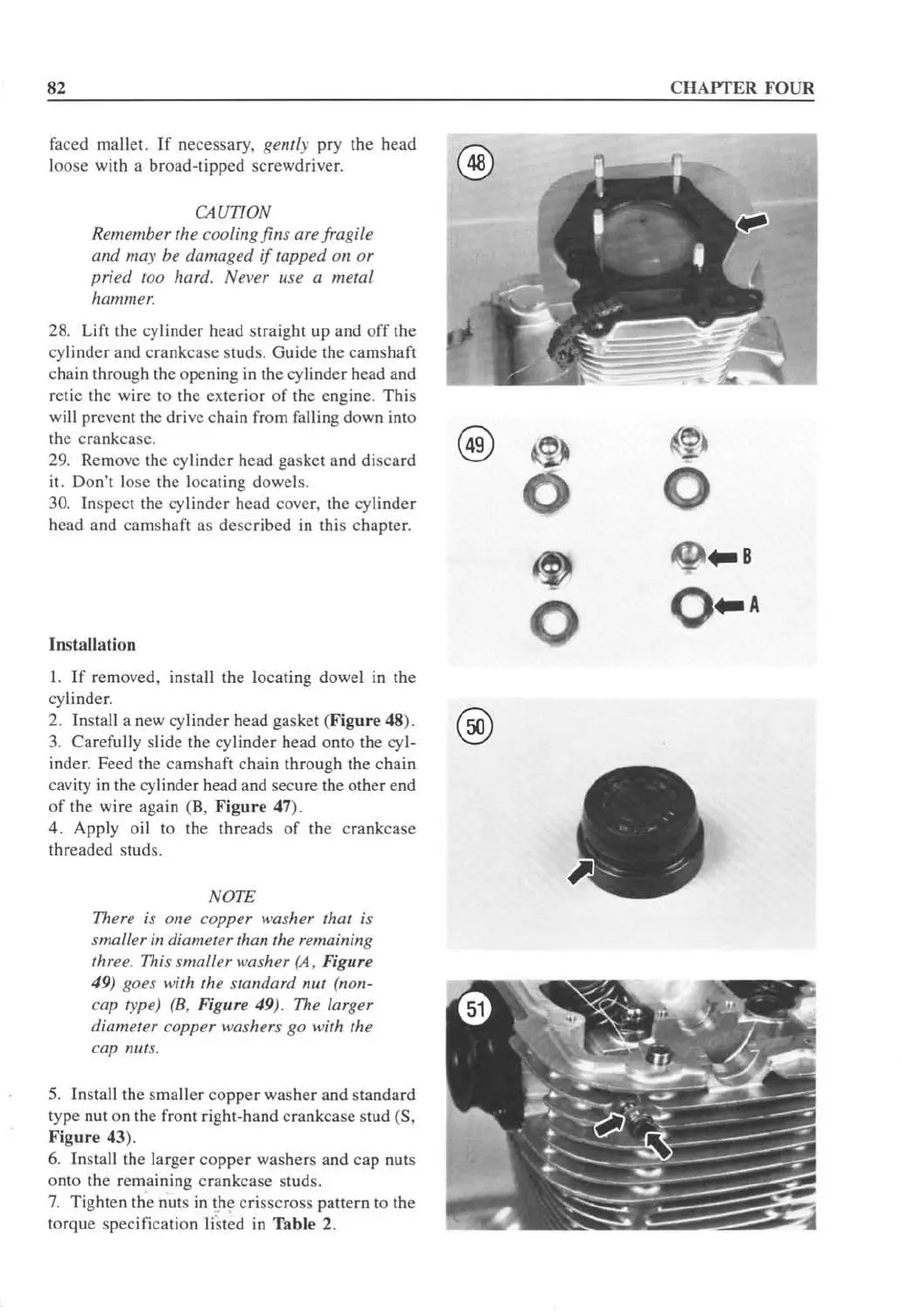

There is

one

copper

washer that is

smaller

in

diameter Ihan the remaining

Ihree.

nlis

smaller

washer (A, Figure

49) goes with the standard nut (non-

cap

rype) (8, Figure 49).

The

larger

diamet

er

copper

washers

go

with the

cap

nuts.

5.

In

stall the smaller

cop

per washer and standard

type nut on the front right-hand crankcase stud

(5.

Fi

gu

re 43).

6.

Insta

ll

the larger copper washers and cap nuts

onto the remaining crankcase st

ud

s.

7.

Tighten the nuts

in

~he

crisscross pattern

10

the

torque speci

fi

cation

li

sted

in

Table

2.

•

o

CHAPTER

FOUR

~

"B

0 " A

Loading...

Loading...