118

1

0.

In

stall the thrust washer (

Figure

188) and the

dri

ve

pin (

Figure

)87).

11

. Align the notch

in

the oil pump drive sprocket

with the drive pin and

in

sta

ll

the o

il

pump drive

sprock

et

(

Figure

186)

onto

the oil pump.

12

. Pull up on the shaft and install the circlip

(Figure

185

) securing the oil pump driven sprocket

to the o

il

pump. Make s

ur

e the circJip is properly

seate

d in the shan groove.

13.

Assemble the crankcase as described

in

this

chap

ter.

Inspection

Replacement parts a

rc

not

avai

la

ble for

th

e oil

pump.

If the

oi

l pump

is

nOI

opcr

aling prope

rl

y.

th

e entire oil pump assem

bl

y

mu

st be replaced.

CAIJTION

Do

liD/try

10

disassemble the

oil

pump

as replacement parts

lI/1d

iockwlIshers

are

nOI al'ailable.

I. ROlate the drive shaft (

Figure

190). If there

is

any binding

or

signs

of

wear: replace the o

il

pump

assembly.

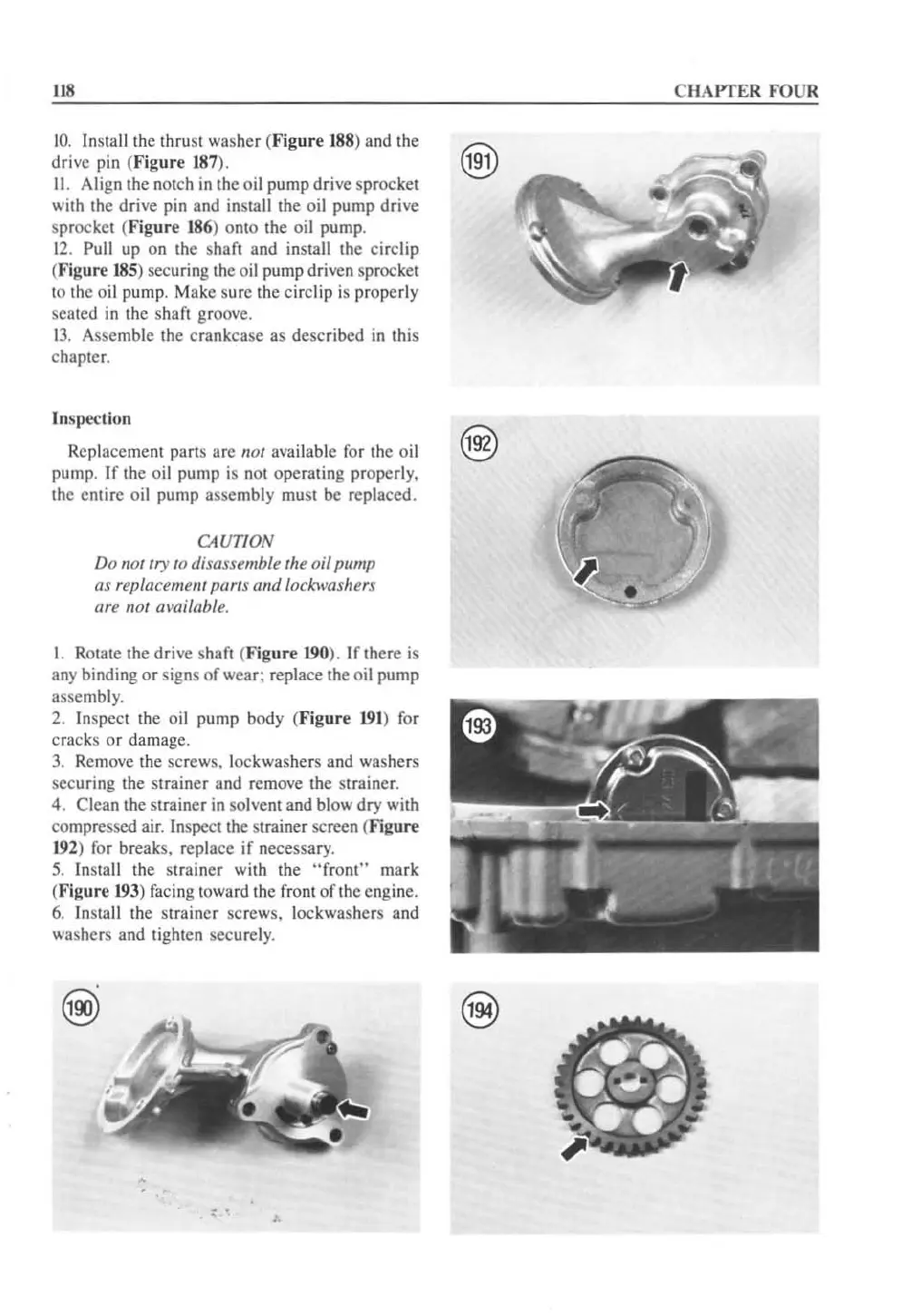

2.

In

spect the oil pump body (

Figure

191)

for

cracks or damage.

3.

Remove the screws. lock

wa

shers and washers

securing the strainer and remove the strainer.

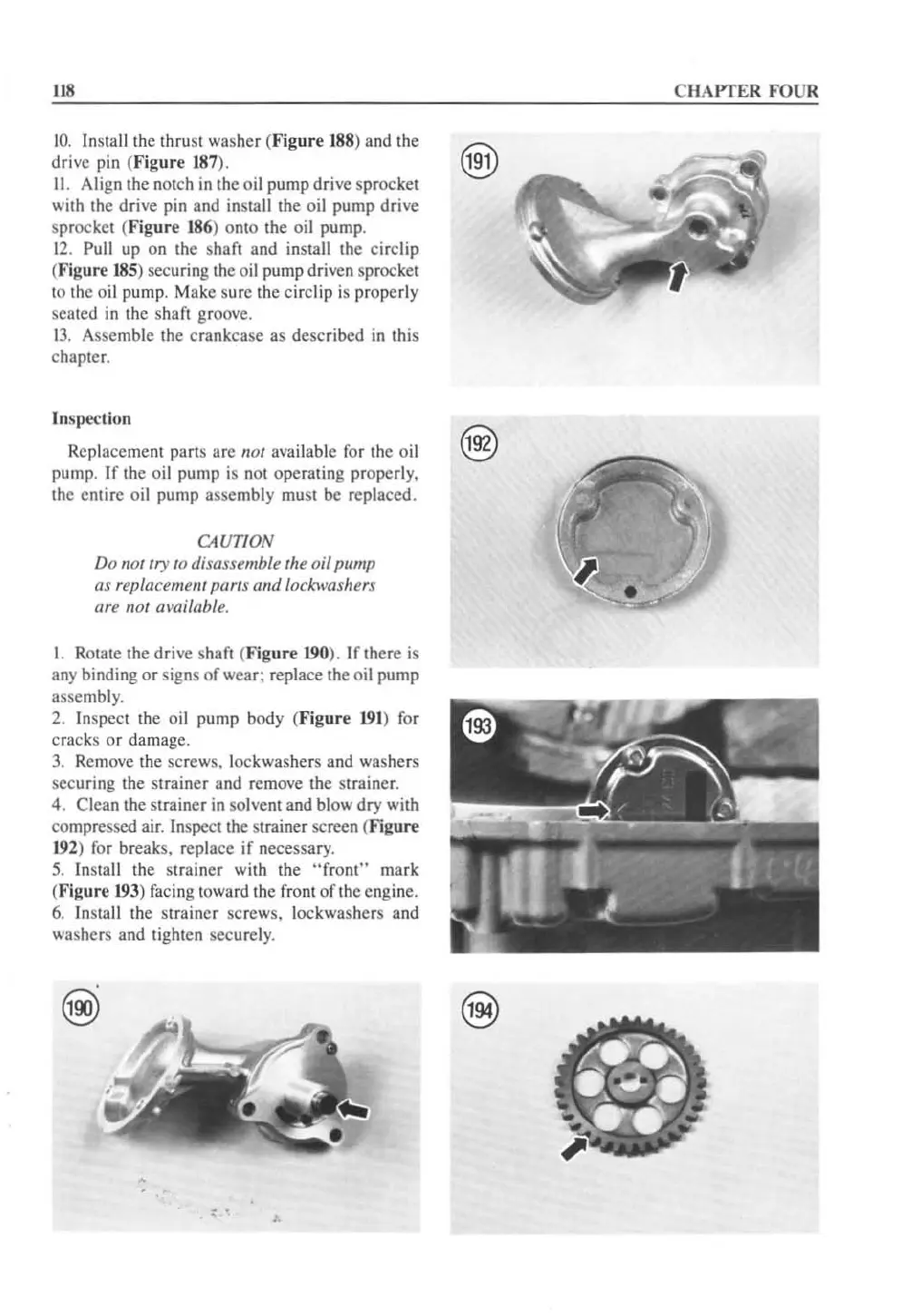

4. Clean the strainer

in

so

lv

ent and blow dry with

compressed air.

In

spect the

st

rainer screen (Figure

192

) for breaks. replace if necessary.

5.

Install the str

ai

ner with the

"front"

mark

(Figure

193

) fac

in

g toward the front

of

the en

gi

ne.

6.

In

stall the strainer screws. lock

wa

shers and

washers and tighten securel

y.

, .

CHAPTER FOUR

Loading...

Loading...