ENGINE

The crankcase is made in 2 halves

of

precision

diecast aluminum and is

of

the " thin-wall

ed"

type.

To avoid damage. do not hammer nor pry on any

of

the exterior or inreri

or

projected walls. These

areas

aTC

eas

il

y damaged. They are assembled

without a gasket and 2 locating dowels align the

crankcase halves when they arc bolted together.

Since the crankcase is assembled

wilhoUi

a

gasket. a specific seal

ant-Three-Bond

No.

1216

is

required to seal the case halves together. This

specific

type

of

sealant is the only type specified

by

U.S. Suzuki and is available fr

om

mo

sl

Suzuki

dealers.

It

is

a hardening type

of

sealant but it

retains

it

elasticity even when subjected to cngine

heal.

Other

typ

es

of

seala

nt

. even

th

ose

manufactured

by

Three

Bond, will eventually

become b

ri

tt

le which will lead to an oil leak.

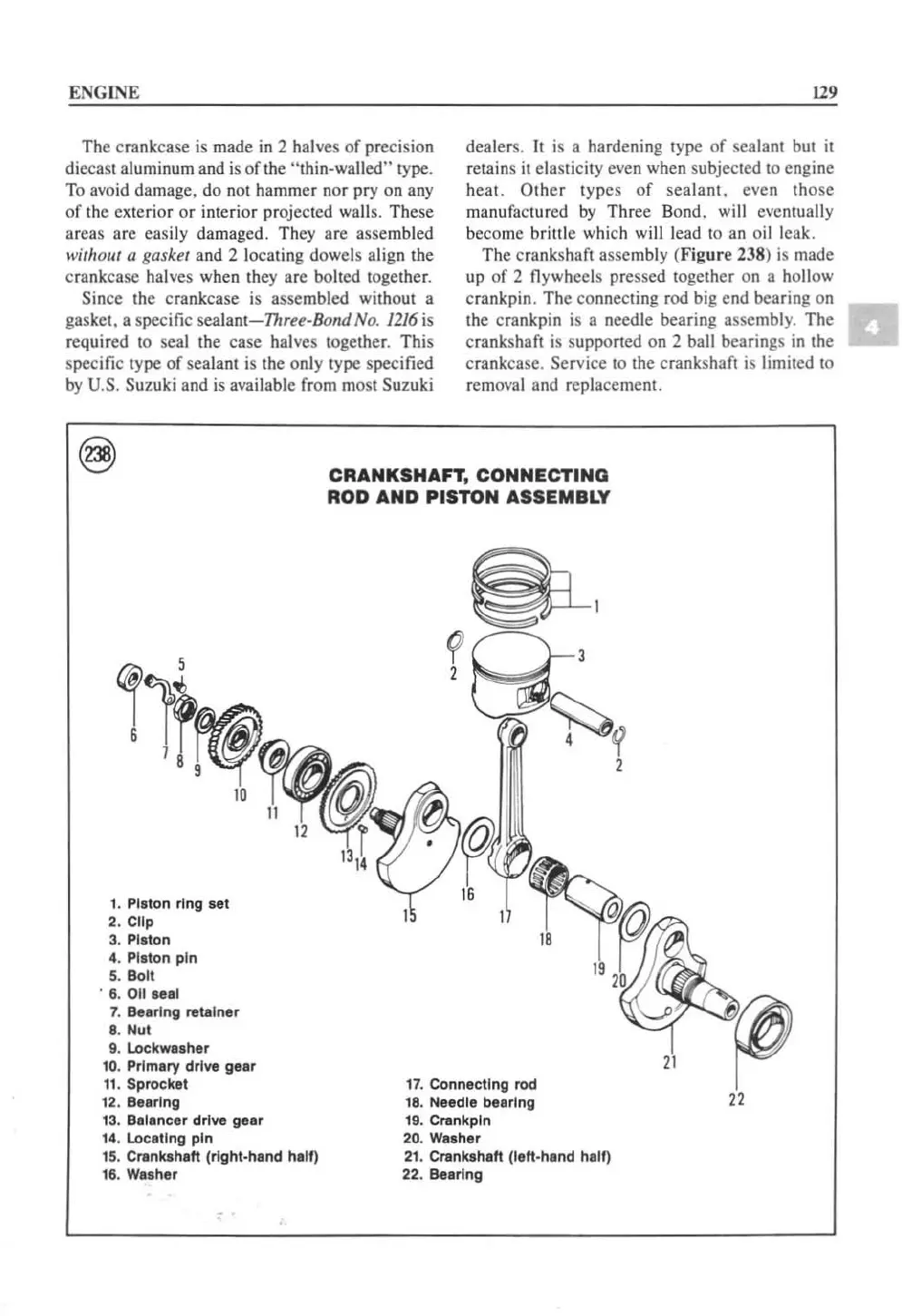

Th

e crankshaft assembly (

Figur

e 238) is made

up

of

2 flywheels pressed together

on

a hollow

crankpin . The

co

nn

ecting rod big end bearing on

the crankpin is a needle bearing assembly.

The

cra

nk

shaft is supported on 2 ball bearings

in

the

crankcase. Service to the crankshaft

is

limited to

removal and replacement.

CRANKSHA".

CONNECTING

ROD

AND

PISTON

ASSEMBLY

1. Pla

ton

ring

..

t

2.

Clip

3. Pla

lon

4. Platon p

in

5.

Bolt

.

6.

Oll

..

al

7. Bearing retlliner

8.

Nut

9.

Lockwalher

10

. Primary drive

gear

11.

Sprocket

17

. Connecting rod

12.

B

ea

ri

ng

18

. Needle bearing

1

3.

Balancer

drive

gear

19

. Crankpln

14.

locating

pin 20. Washer

15

. Crankshaft

(right-hind

hl

lf)

21

. Crankshaft

(Iaft-hlnd

half)

16.

Wa,he,

22. Bearing

Loading...

Loading...