CLUTCH

@

, .

155

II

.

In

spect the damper

spr

in

gs (

Figure

25). If they

afC

sagged

or

broken the QUier housing

mu

st

be

replaced.

12

.

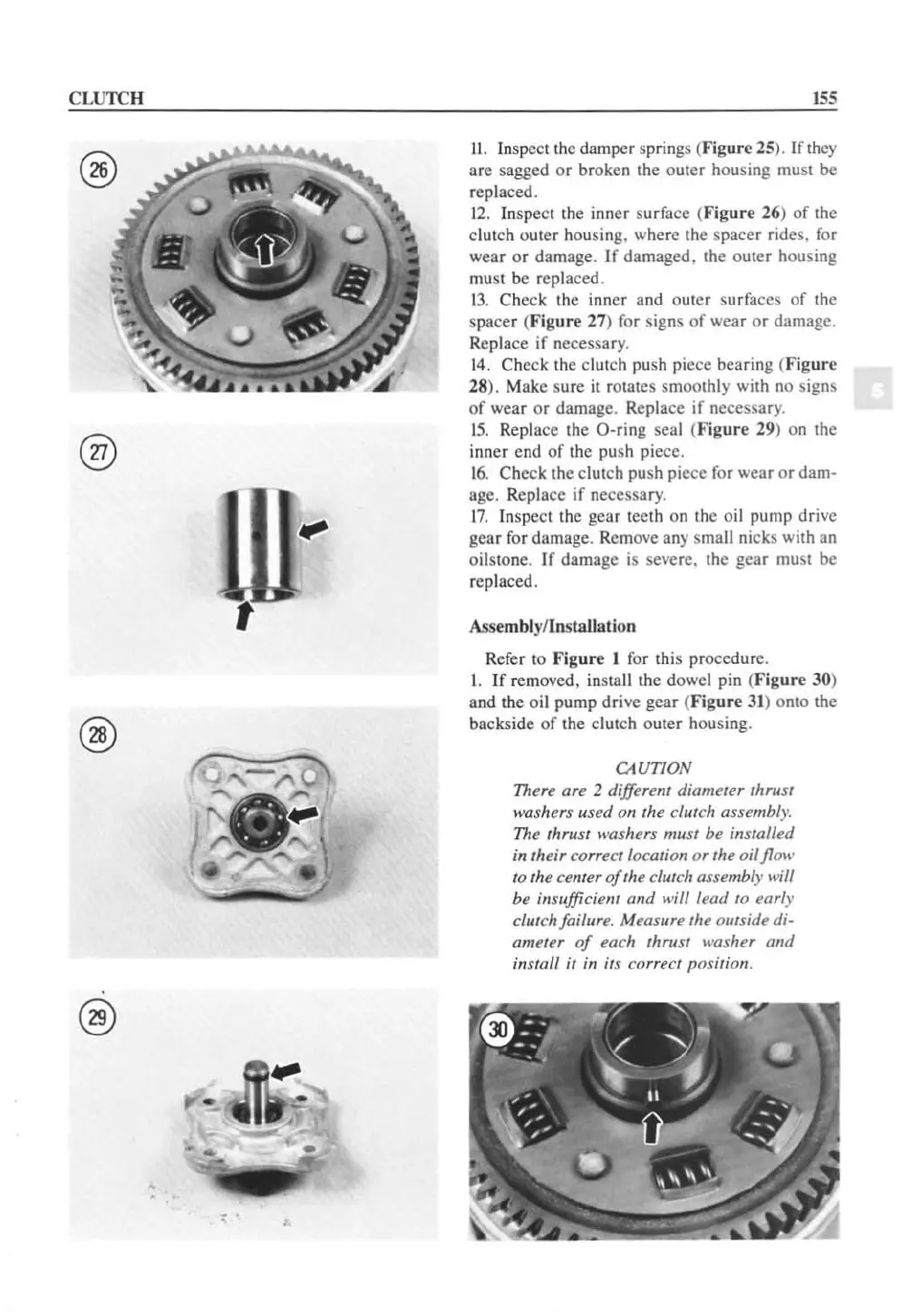

In

s

pe

ct the inner surface (Fig

ur

e 26)

of

the

clutch outer hou

si

n

g.

where the spacer rides. for

wear

or

damage.

Ir

damaged. the ouler housing

must

be

replaced.

1

3.

Check the inner and out

er

surfaces of the

spacer (

Figure

27) for signs

of

wear

or

damage.

Replace if necessary.

14.

Check the clutch push piece bearing (Fig

ur

e

28). Make sure

it

rotates smoothly with no signs

of

wear

or

damage. Replace

if

necessary.

1

5.

Replace the O-ring seal (Figure 29) on the

inner cnd

of

the push piece.

1

6.

Check the clutch push pie

ce

for wear

or

dam-

age. Replace

if

necessary.

1

7.

Inspect the gear teeth on the oil pump drive

gear for damage. Remove any small nicks with an

oilstone. If damage is severe. the gear must

be

replaced.

Assemblyf

In

sta

ll

ation

Refer to

Figure

1 for this procedure.

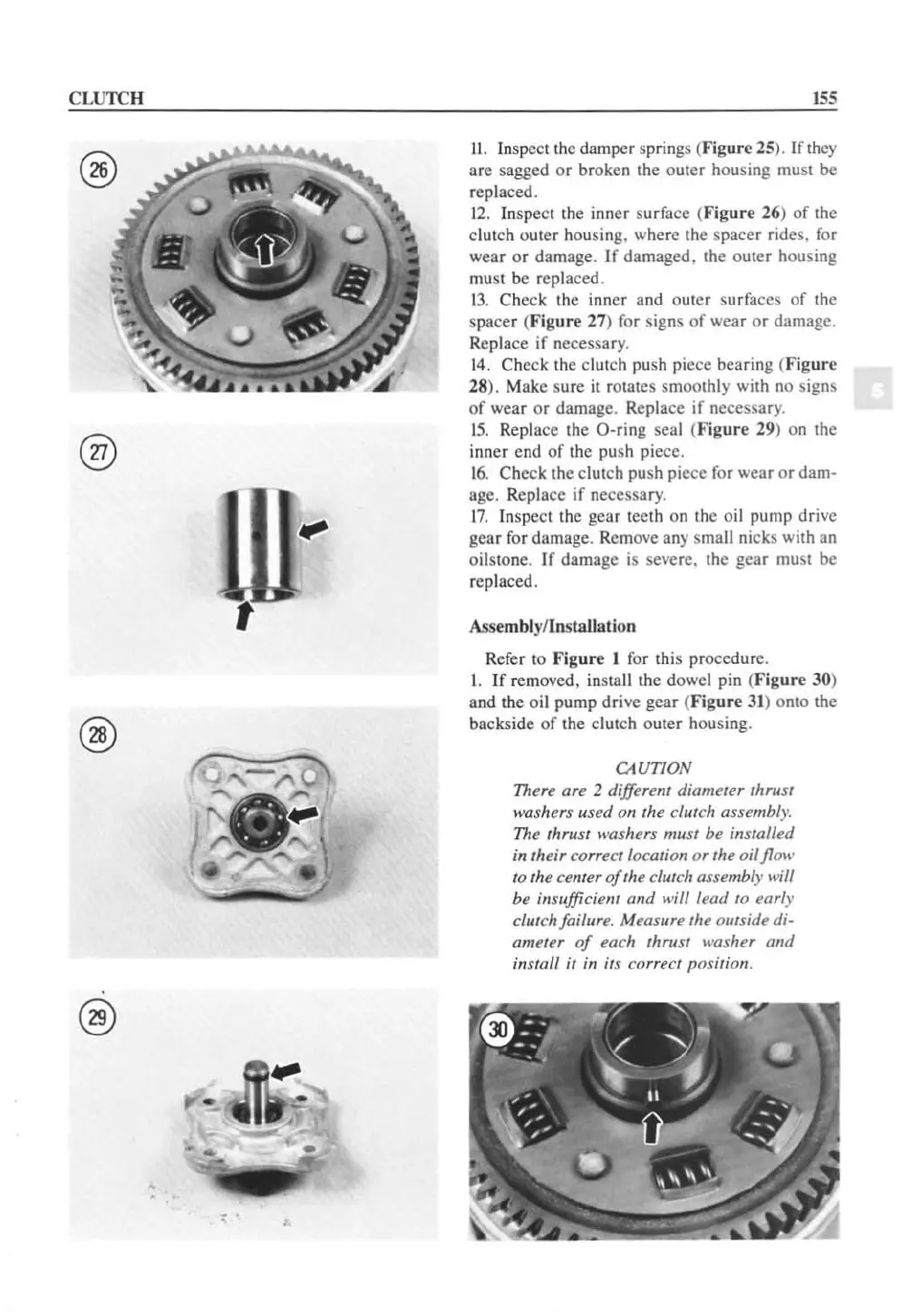

I. If removed, insta

ll

the dowel pin (

Figure

30)

and the oil pump drive gear (

Figure

31

) onto the

backside

of

the clutch outer housing.

CAUTION

There are 2 different diameter thrust

washers used on the clut

ch

assembly.

The thrust washers

mllst be installed

in their correct location

or

the

oilflow

to

the center

of

the clutch assembly

lI'ill

be insufficient alld will lead

to

early

clutch failure. Measure the outside

di-

ameter

of

each thrust washer

and

ins

ta

ll it

in

its correct position.

Loading...

Loading...