214

14.

Ti

ghten the cover bolts securely.

WARNING

Be

sure

10

secure the alternator

e/eclri

caJ

cable

and

emission control

hoses back to the frame as shown

in

Fi

gure

/0.

If

the electrical cable is not

secured as shown, it will more orer and

the drive

belt

wj{f

rub on it.

Th

e drive

bell

will wear (llrollgh Ihe insulation

and

all

electrical short or open will

occ

ur.

1

5,

Install the tie wrap

(F

igur

e

10

) securing the

alternator electrical cable and emission control

hoses

to

the frame.

16.

Make sure the electrical co

nn

ector

is

free

of

corrosion and

is

tight.

17.

Fill the engine with the recommended type and

quantity of oil as described und

er

Engine Oil and

@4

Filter Change in Chapter Three.

Rotor Testing

The rotor

is

permanently magnetized and cannot

be

tested except

by

replacement of a rotor known

to

be

good. A rotor can

lo

se magnetism fr

om

o

ld

age

or

a sharp blow. If defective, the rotor must

be

replaced: it cannot be remagnetized.

Rotor Removal/Installation

NOTE

This

procedure

is

shoWTJ

with the

engine remove frolll the

frame

and

partially disassembletl

for

clarity. It is

not necessary to remove the engine to

remove the rotor assembly.

\.

Remove

the stator assembly

as

described in this

chapter.

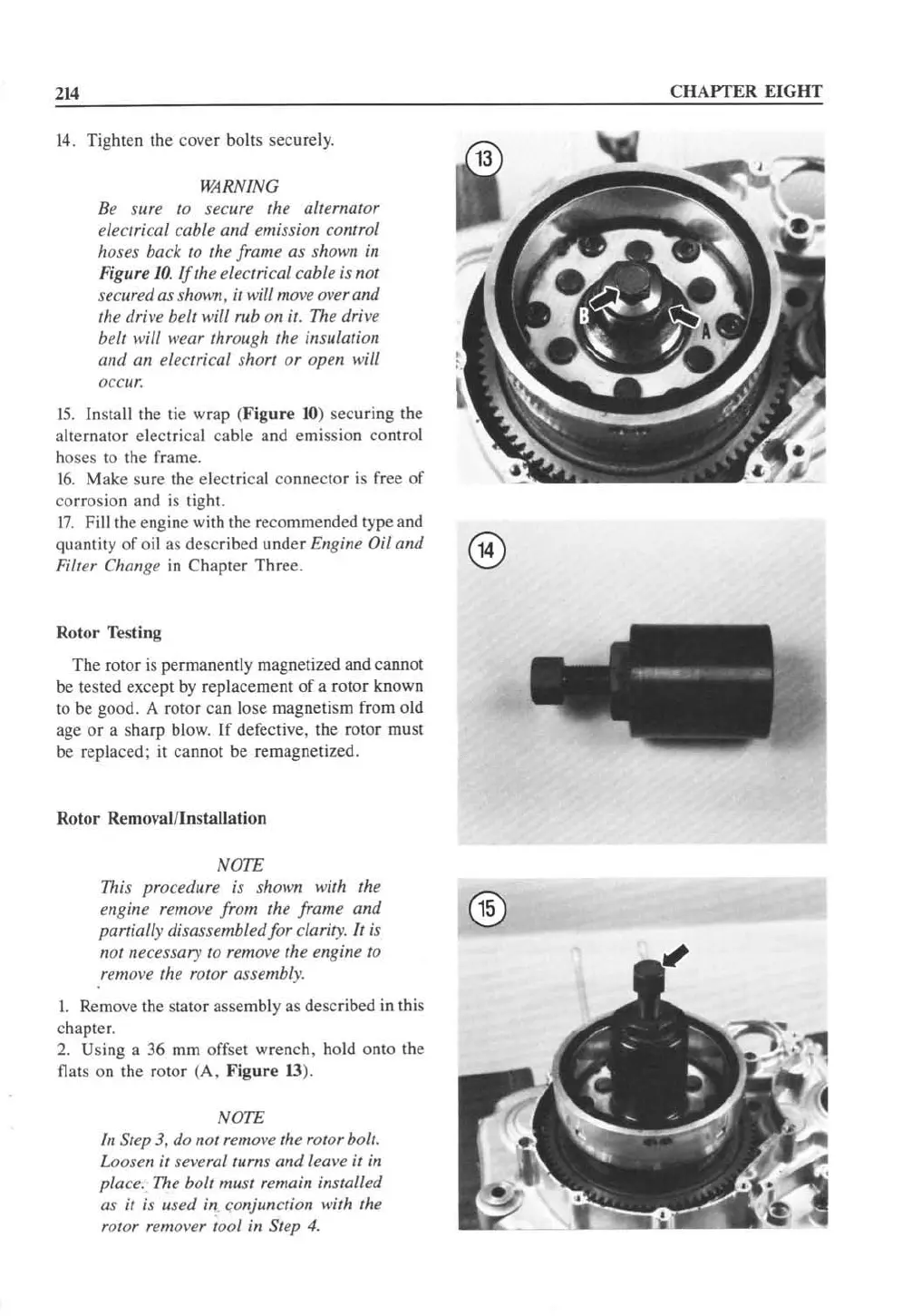

2.

Us

in

g a 36

mm

of

fset

wrench, hold onto the

Oat

s on

th

e rotor (A. Figure

13

).

NOTE

In

Step

3,

do

not

remo~'e

the rotor bolt.

Loosen it

severallll

rns

and

leave it in

place. The

bolt

must remain installed

as

it is usetl

in

(o

njunction with the

rotor

remover tool in Step

4.

CHAPTER EIGHT

Loading...

Loading...