U2

scribe. Hold your thumb

ove

r onc edge

of

the clip

when removing

it

to

prevcnI

the clip from springing

out.

5.

Usc a proper size wooden dowel or socket

extension and push out the piston pin.

CAUTION

Be

ca

r

ef

lll when r

emQ\·

j"8

th

e pin to

(II'oid (/amaging llle connecting rod. If

if

is

1I

ecessary to gently

rap

the pin

to

remOl't! it. be SIIre that the

pisto/l

is

properly supported so Ihat lateral

shock is

110/

transmilled

to

the

fowu

cOl/necting

rOll

bearing.

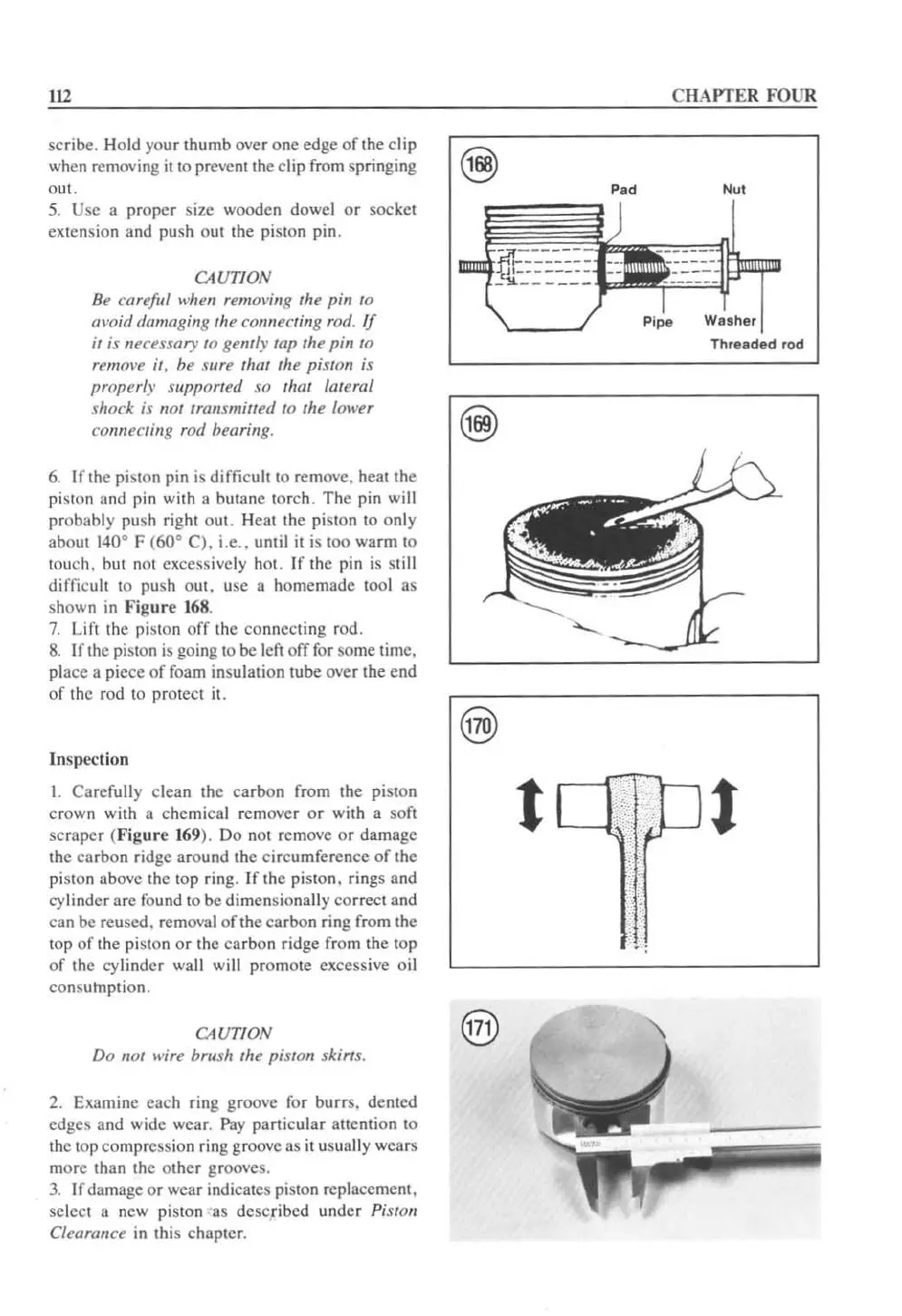

6.

If the piston pin is difficult to remove. heat the

piston and pin with a butane torch. The pin will

probably push right

OUI.

Heal the piston to o

nl

y

about \40" F (60" C). i.e .. until

it

is 100 warm to

lOuch, but not excessi

ve

ly hot. If the pin

is

still

difficult to push out. use a homemade tool as

shown

in

Figure

168

.

7.

Lift the piston

off

the co

nn

ecting rod.

S.

If

th

e

pi

ston

is

going to be left off

for

some lime.

pl

ace a piece of foam insulation tube

ove

r the end

of

the rod to protect it.

Inspection

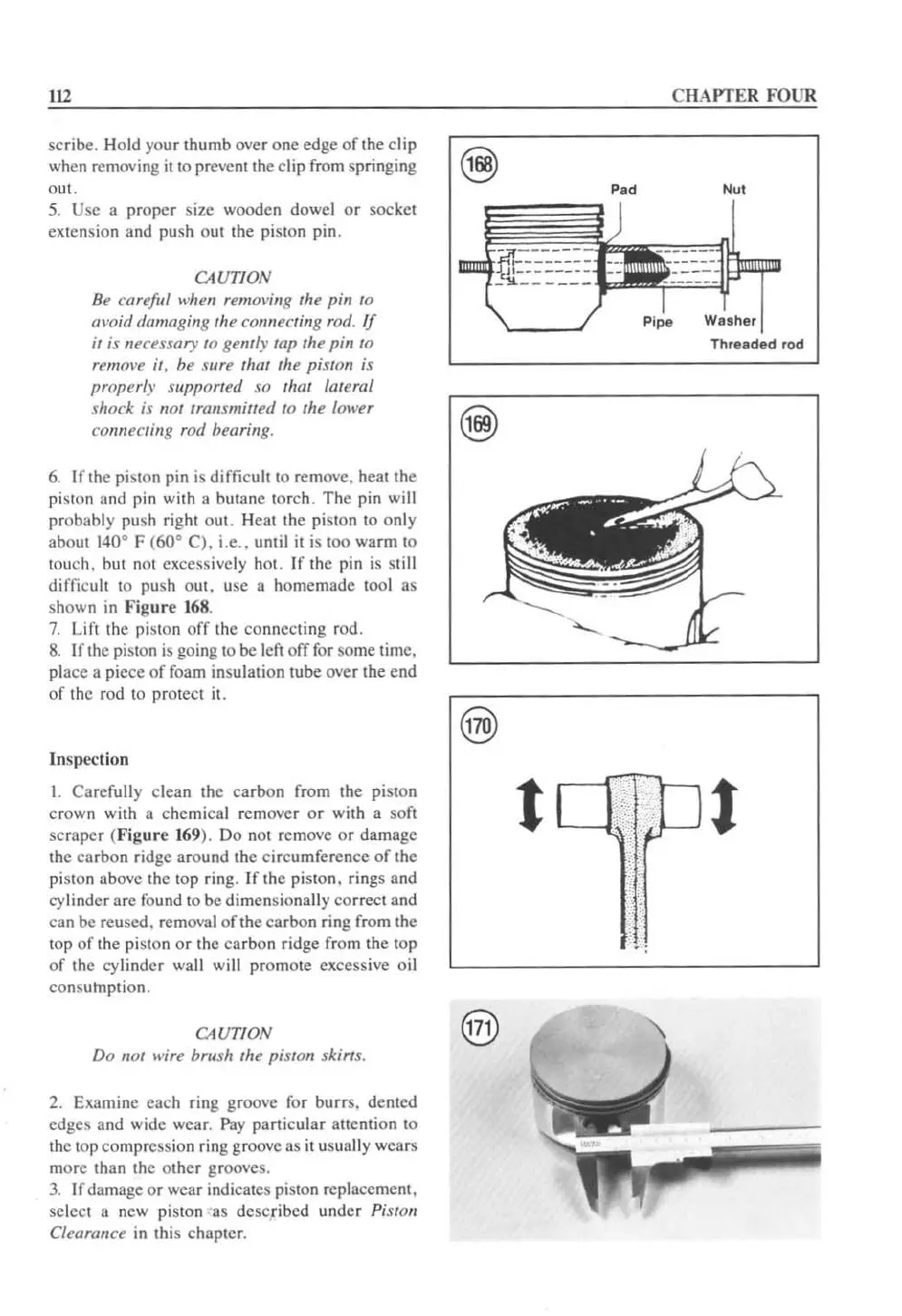

I.

Ca

refully clean the carbon

fr

om the piston

crown with a chemical remover or with a soft

scraper (I'

igure

16

9). Do not remove or damage

the carbon ridge arou

nd

the circumference

of

the

piston above the top rin

g.

If the

pi

ston. rings and

cylinder are found to be dimensio

na

ll

y correct and

can

be

reused. rem

ova

l

of

the carbon ring from the

top

of

the piston or the carbon ridge from

th

e

tOp

of

the

cy

linder wall will promote excess

iv

e oil

consutnption.

CAUT

IO

N

Do not wire brush the piston skirt

s.

2. Examine each ring groove for burrs. dented

edges a

nd

wide wear.

Pa

y particular anent ion to

the

lOp

compression ring groove as it usua

ll

y wears

more than the

other

grooves.

3.

If da

ma

ge or wear indicates piston replaceme

nt

.

select a new

pi

ston ·as described under Piston

Clearance

in

this chaptcr.

CHAPTER FOUR

P

••

""

Threaded rod

Df

. ,

Loading...

Loading...