252

NOTE

Insert a piece

afvinyl

tubing or wood

in the caliper in

pla

ce

of,Ile

brake disc.

That

wa

y

if

the brake fever is

ifllldl'erlenily

squeezed, the

1);

SIOn

wifl

110/

be/arced

OUI

of/he

cylinder.

If/h

is

does happen , the caliper may

hOI'e

to

be

disa

sse

mbled

to

restal

th

e piston

and Ihe

$}

'S

fem

will

hOI

'e

10

be

bled.

By

using

th

e wood. bleeding

th

e brake is

n

o/

necessa

ry

when

installing

th

e

wheel.

In

sta

ll

ation

I. Make s

ur

e

the

ax

le bearing surfa

ces

oflhe

fork

sliders and axle

ar

c free from

burr

s and n

ic

ks.

2. Remove the vinyllubing or

pi

eces of wood from

the brake caliper.

3.

Position the wheel

in

place and carefully insert

th

e brake disc between the brake pads in the caliper

asse

mbly

.

4. Make sure the wheel spac

er

is

in

place on

eac

h

side

of

th

e hub.

5.

Apply a light coat

of

grease to the front altle.

In

sert the front axle from the left-hand side through

the wheel hub.

6.

Tighten the front axle to the torque speci

fi

cation

listed

in

Table

I.

7.

In

stall the front caliper assembly as described

under

Fr

o

nt

Brake Caliper RemoWll/lnstaliation

in

Chapter Ele

ve

n.

8. Remove the wood block(s) from under the

engine and frame.

9.

With the front brake applied, push do

wn

hard

on the handlebars and pump the forks several times

to

se

at the front altle.

10.

Tighten the front axle and front axle pinch bolt

to the torque specification listed in Table

I.

11.

After the wheel

is

completely installed. rotate

it several times to make sure that

it rotates freely.

Apply the front

brake as many times as necessary

to make sure the brake pads are against the brake

disc correctly.

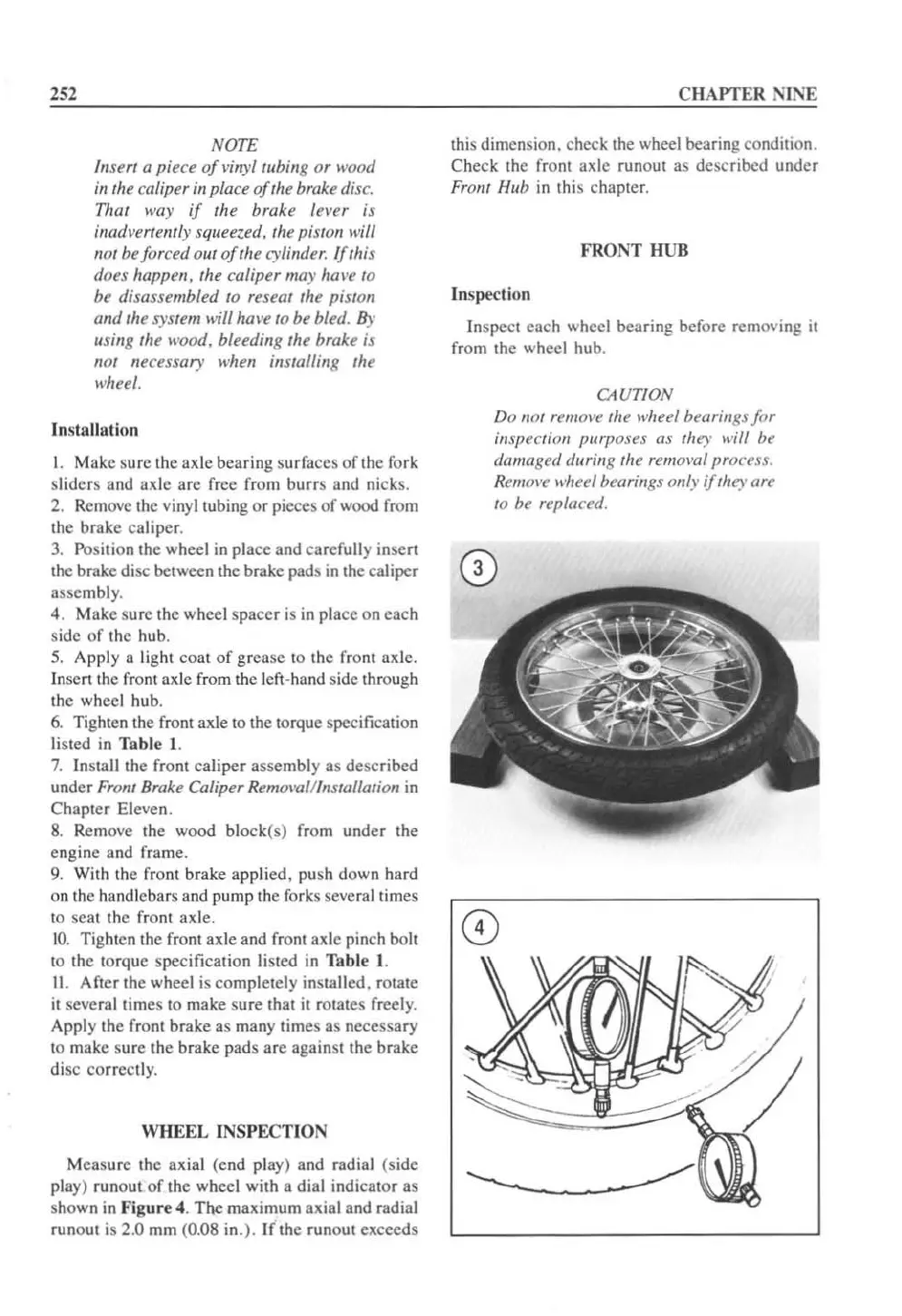

WHEEL INSPECTION

Meas

ur

e the axial

(e

nd play) and radi

al

(side

play)

runoul

of

the wheel with a dial indicator as

sho

wn

in

Figure

4.

The

maximum axial and radial

runout is

2.0 mm (0.08

in

.). If the runout eltceeds

CHAPTER NINE

this dimension, check the wheel bea

ri

ng

condition.

Check the front axle runout as described under

Fro

nt

Hub

in

this chapter.

FRONT

HUB

Inspection

In

spect each wheel bearing before removing

it

from the wheel hub.

CAUTION

Do

1101

remOl·e Ihe wheel

hearings/or

inspection

purposes

as

Ill

ey will

be

(lomo

ged

during llle rem

om/,Jrocess.

Remove wi/eel

beari

ll

gs only

if

tltey

are

10

be

replace(J.

Loading...

Loading...